Novel chuck

A chuck, a new type of technology, applied in the direction of the chuck, can solve the problems of increasing the burden on the spindle and bearing of the machine tool, affecting the processing accuracy of the product, affecting the stability of the machine tool, etc., and achieving convenient and clear adjustment, reduced overall weight, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

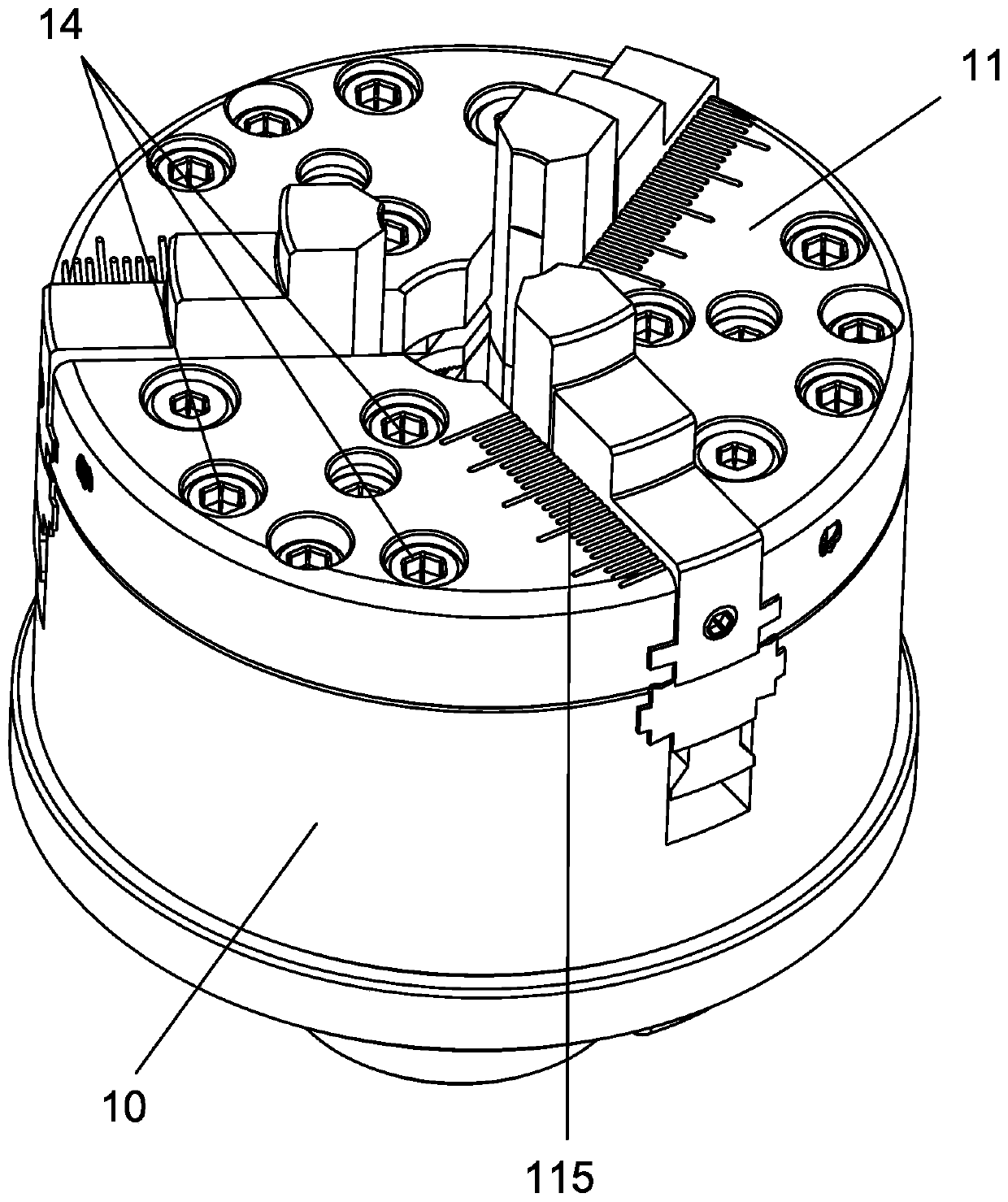

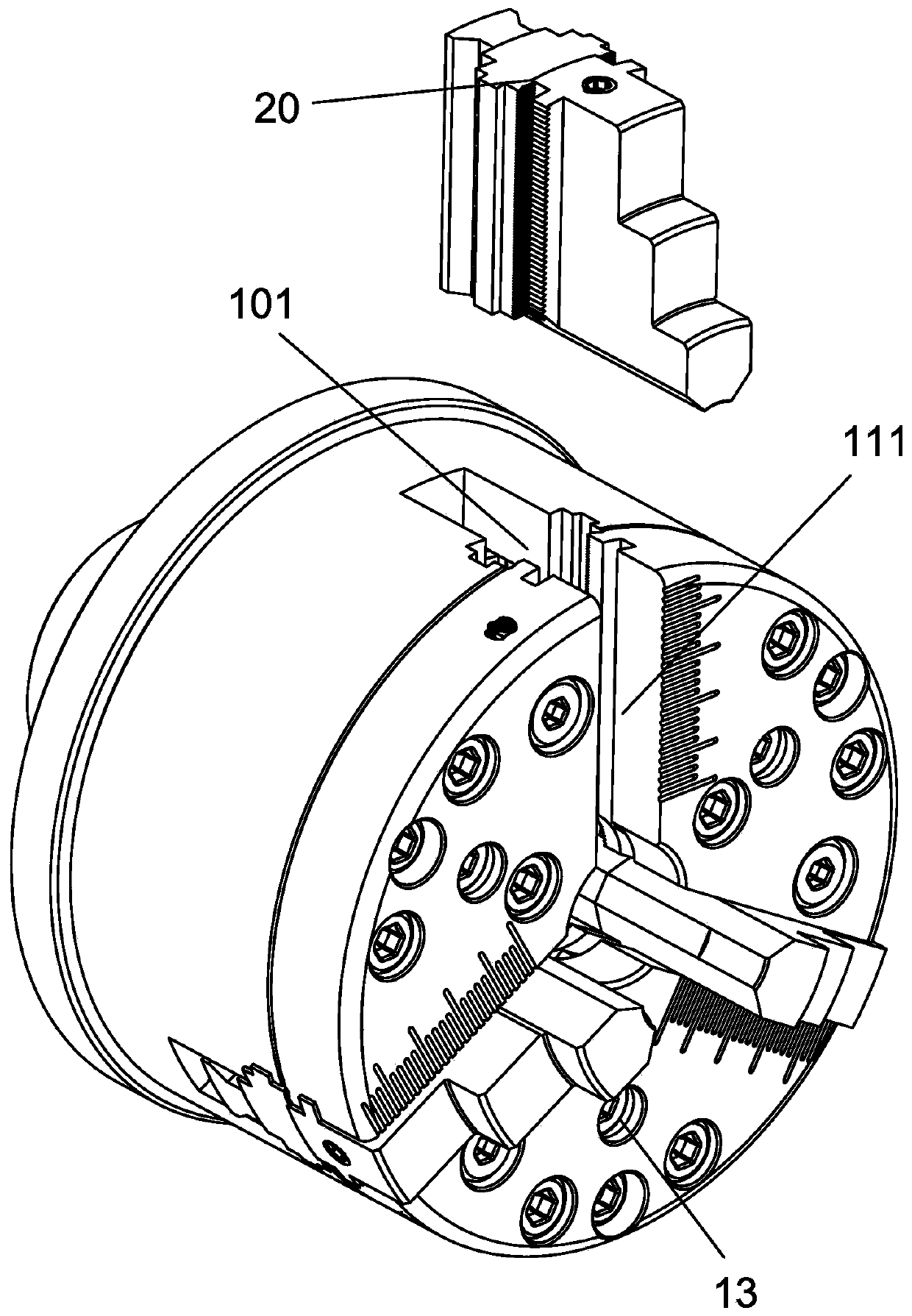

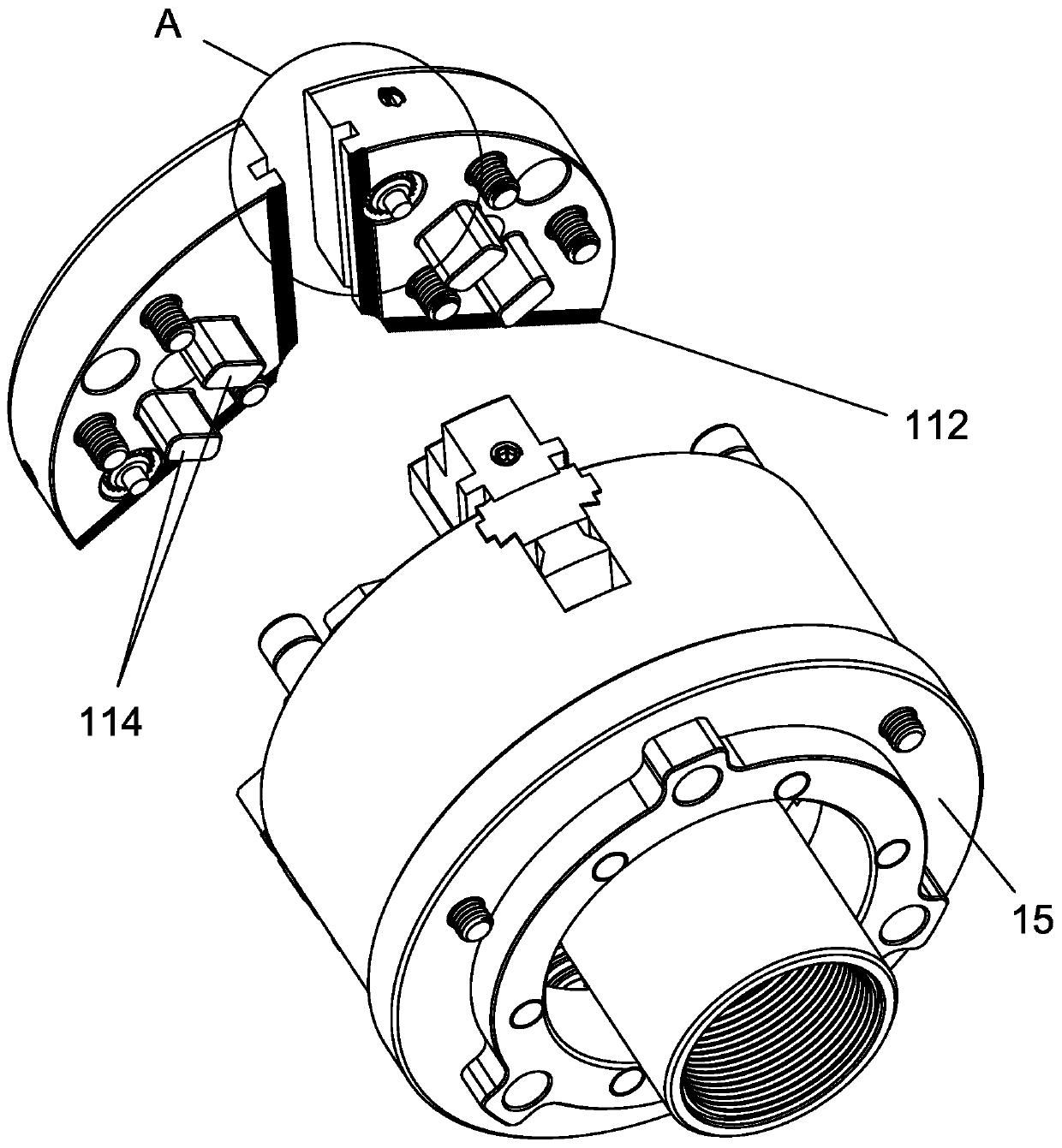

[0054] refer to Figure 1 to Figure 13 ,Such as Figure 1 to Figure 13 A new type of chuck shown includes a housing 10, jaw assemblies 20 uniformly distributed along the circumferential direction of the housing 10, the end surface of the housing 10 is provided with a jaw locking cover 11, and the jaw assembly 20 slides in the radial direction relative to the housing 10 to adjust to the required clamping size and is fixed by the claw locking cover 11; the housing 10 is equipped with a clamping drive device (not shown) The control panel 12, the jaw assembly 20 is controlled by the control panel 12, so that it can be clamped or loosened on the above-mentioned clamping size;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com