Environment-friendly intelligent unloading system applied to gravel material field

An environmentally friendly, sand and gravel technology, applied in loading/unloading, cleaning devices, transportation and packaging, etc., can solve problems such as hidden dangers, unfavorable energy conservation and emission reduction, and reduce energy consumption of enterprises, to avoid intervention, reduce noise, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in further detail below. It should be understood that the description of the embodiments of the present invention herein is not intended to limit the protection scope of the present invention.

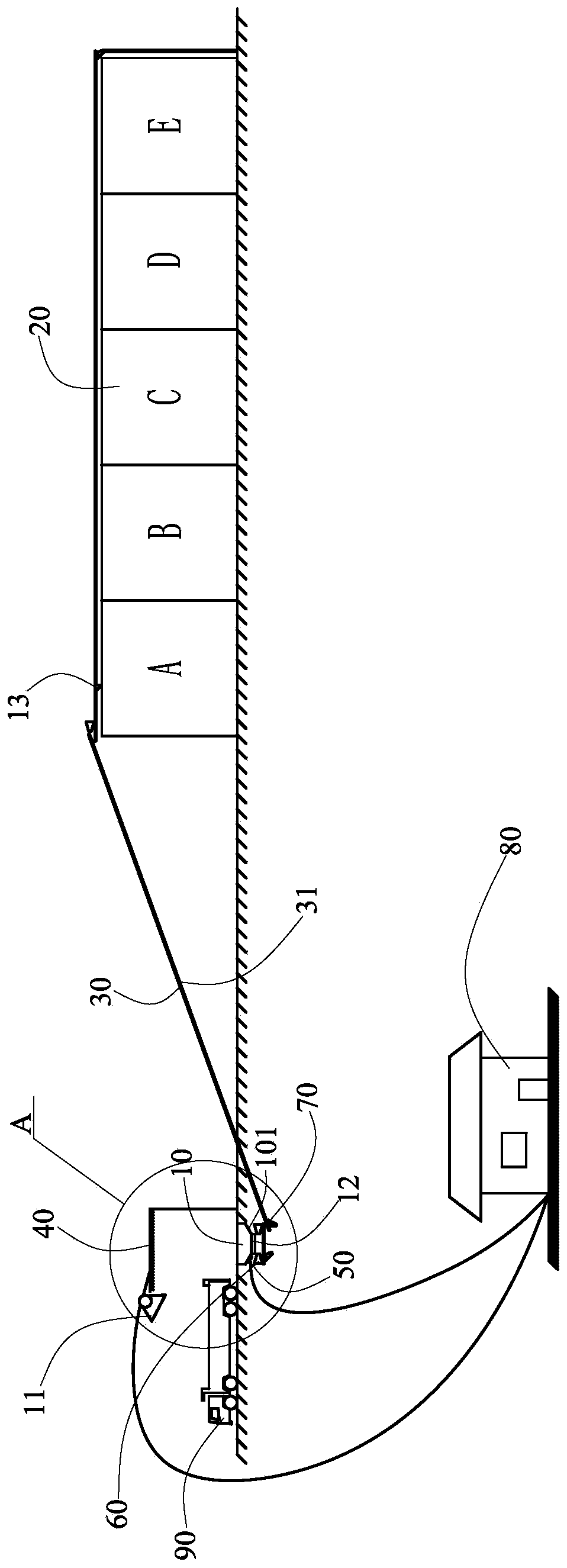

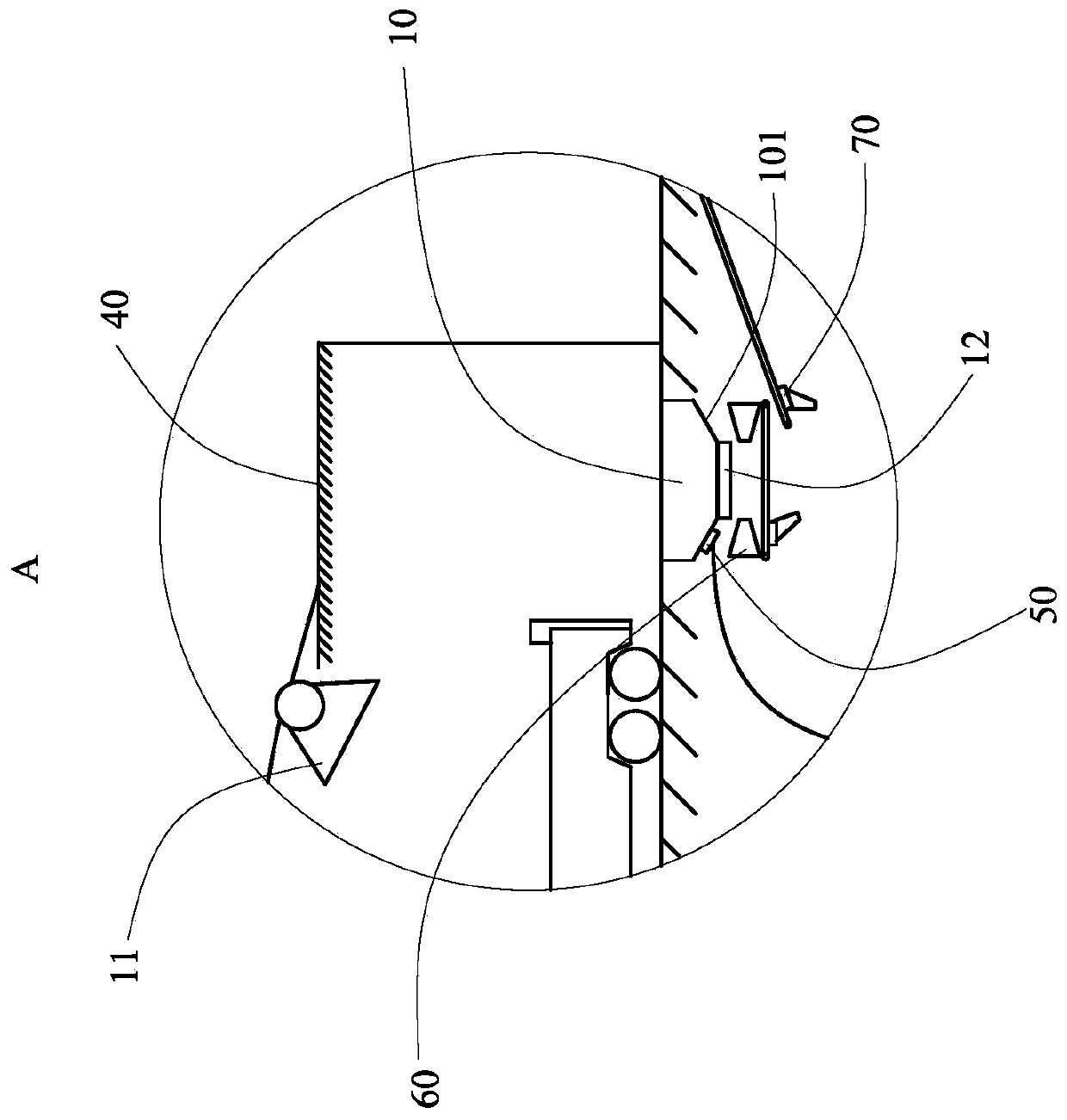

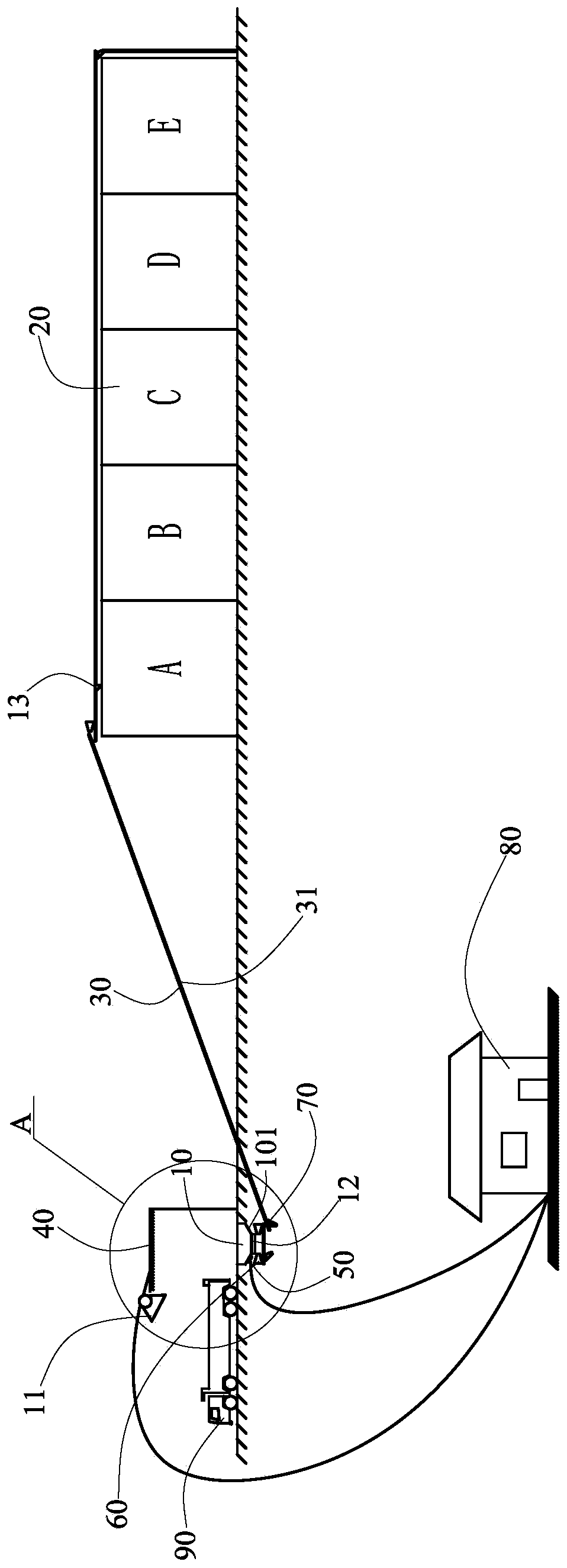

[0019] Such as figure 1 with figure 2 As shown, it is a schematic structural diagram of an environmentally friendly intelligent unloading system applied to a sand and gravel yard provided by the present invention. The environmentally friendly intelligent unloading system applied to the sand and gravel yard includes a receiving device 10 set below the ground, at least one storage bin 20 set on the ground, and one receiving device 10 and the The material conveying device 30 between the storage bins 20, an atomizing device 40 arranged above the material receiving device 10, a sound sensing device 50 arranged on the material receiving device 10, and a sound sensor device 50 arranged on the receiving device 10 The dust s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com