A kind of preparation method and application of self-dispersing nano bismuth vanadate

A bismuth vanadate self-dispersing technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unstable dispersion and limited application, and achieve good dyeing performance, UV protection performance modification, good The effect of stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

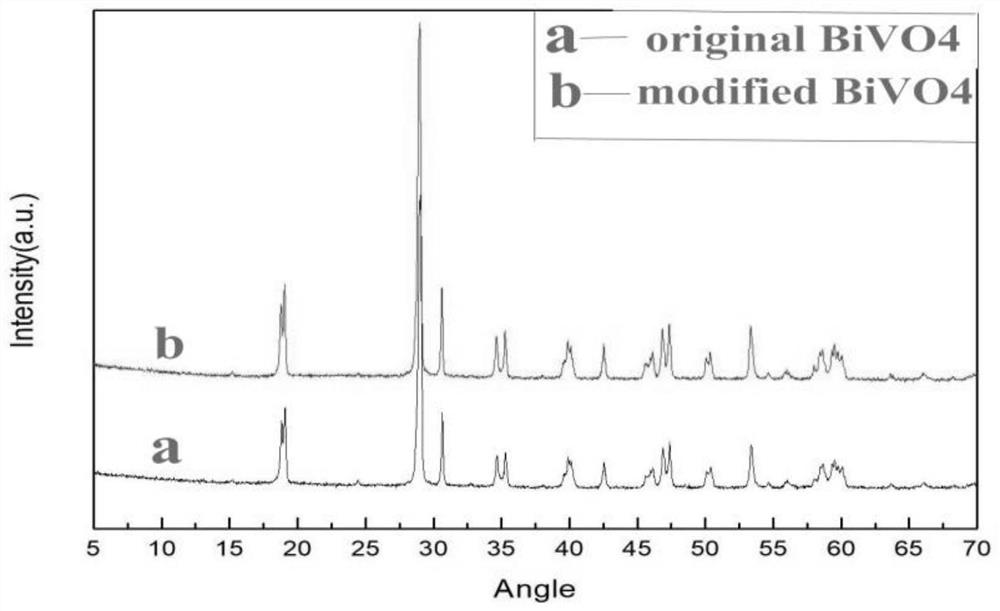

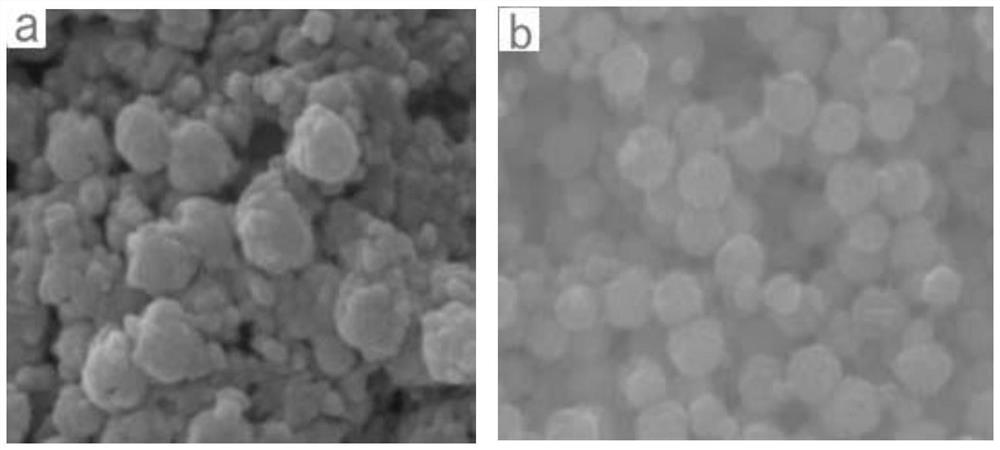

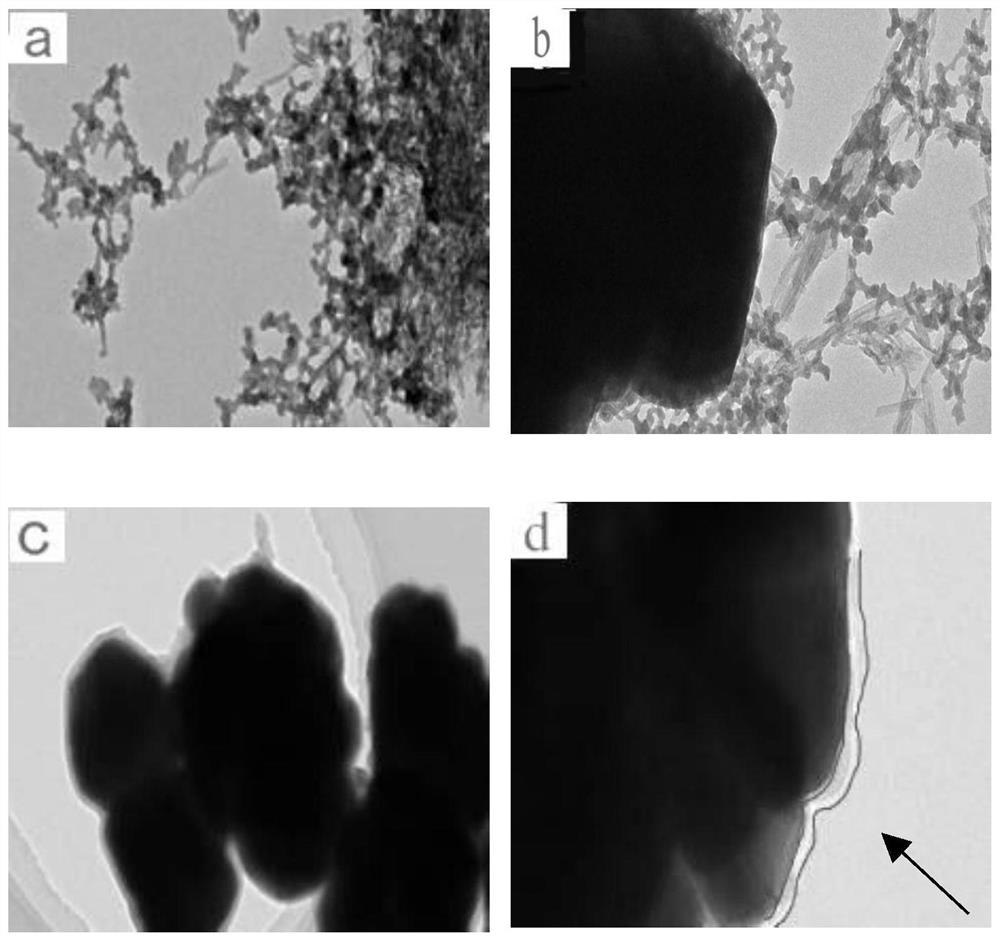

[0042] (1) Preparation of bismuth vanadate: mix 5.0mmol of bismuth nitrate pentahydrate and 5.0mmol of ammonium metavanadate evenly and grind them in an agate mortar until the powder forms a reddish-brown slurry, then stop grinding and transfer to a corundum crucible Then put it into an oven with a temperature of 120°C and dry it continuously for 12 hours, take out the dried product, wash it with absolute ethanol and distilled water for 3 times, and then put it into a high-speed centrifuge for centrifugation (centrifugation at 8000r / min) 20min), the product obtained after centrifugation was dried in a vacuum oven at 70°C for 4h, and the final product was a bismuth vanadate sample.

[0043] (2) Preparation of modified solution: Add 0.228g AGE, 0.714g KH590, 0.1g photoinitiator (isobutyl alcohol ketone) into 30ml ethanol solution, put it on a magnetic stirrer and stir it in the dark for 10min, then put it on Continue stirring for 30 min while irradiating with ultraviolet light u...

Embodiment 2

[0052] The value of the Zeta potential is related to the dispersion stability in the colloidal state. The higher the Zeta potential, the greater the electrostatic repulsion between particles, and the more stable the dispersion system. 0~±5 precipitates quickly, ±10~±20 has poor stability, ±20~±30 has average stability, and ±30~±40 has good stability.

[0053] On the basis of Example 1, explore the addition molar ratio of (3-acrylamidopropyl) trimethylammonium chloride and allyl glycidyl ether (respectively 3:0, 3:1, 3:2, 3 : 3) the impact on the dispersion stability of self-dispersing nano bismuth vanadate, measure potential data, the results are shown in Table 3.

[0054] table 3

[0055]

[0056] As can be seen from Table 3, the Zeta potential of the unmodified bismuth vanadate particles is negatively charged, and the stability is very poor, while the Zeta potential of the modified bismuth vanadate particles is as high as 45.2, which has good stability . It may be that...

Embodiment 3

[0059] The prepared 0.12g modified BiVO 4 Ultrasonic disperse into 50mL water, add 1g sodium carbonate, stir and mix evenly, add 1g cotton fabric, place in a vibrating water bath for dyeing. Dye at a dyeing temperature of 40°C for 30 minutes, then raise the temperature to 80°C at a rate of 2°C / min, and then continue to dye for 30 minutes. After dyeing, put the cotton fabric in an oven and dry it at 80°C. Bake at 150°C for 2 minutes. Finally, the dyed cotton fabric is soaped, dried, washed with water and finally dried again.

[0060] Cut the dyed cotton sample, which is 11cm long and 6cm wide. Use a needle to remove 5mm lines on the top, bottom, left, and right sides of the cloth strip, so that the length of the test complete cotton cloth is 10cm, and the width is 5cm. The upper and lower ends are clamped into the instrument for testing Take a 5cm × 5cm bleached cotton sample and clamp it on the friction head, clamp the dyed cotton to be tested on both ends of the bottom plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com