Method for preparing nano-material-doped polymer film

A nanomaterial and polymer film technology, applied in the field of polymer film preparation, can solve the problems of uneven dispersion and easy shedding of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: The preparation method of the nanomaterial-doped polymer film of the present embodiment is carried out according to the following steps:

[0031] 1. Weigh 0.1% to 20% of hydrophilic organic nanomaterials, 5% to 30% of polymers, and 50% to 94.9% of organic solvents by mass percentage;

[0032] 2. Add the hydrophilic organic nanomaterial weighed in step 1 into an organic solvent for ultrasonic dispersion, wherein the ultrasonic dispersion power is 50w-1000w, and the ultrasonic dispersion time is 0.1h-10h to obtain a nanomaterial suspension;

[0033] 3. Add the polymer weighed in step 1 to the nanomaterial suspension obtained in step 2. After sealing, heat to 25°C-80°C and stir for 1h-48h, and then stand for defoaming for 2h-48h to obtain cast Membrane fluid;

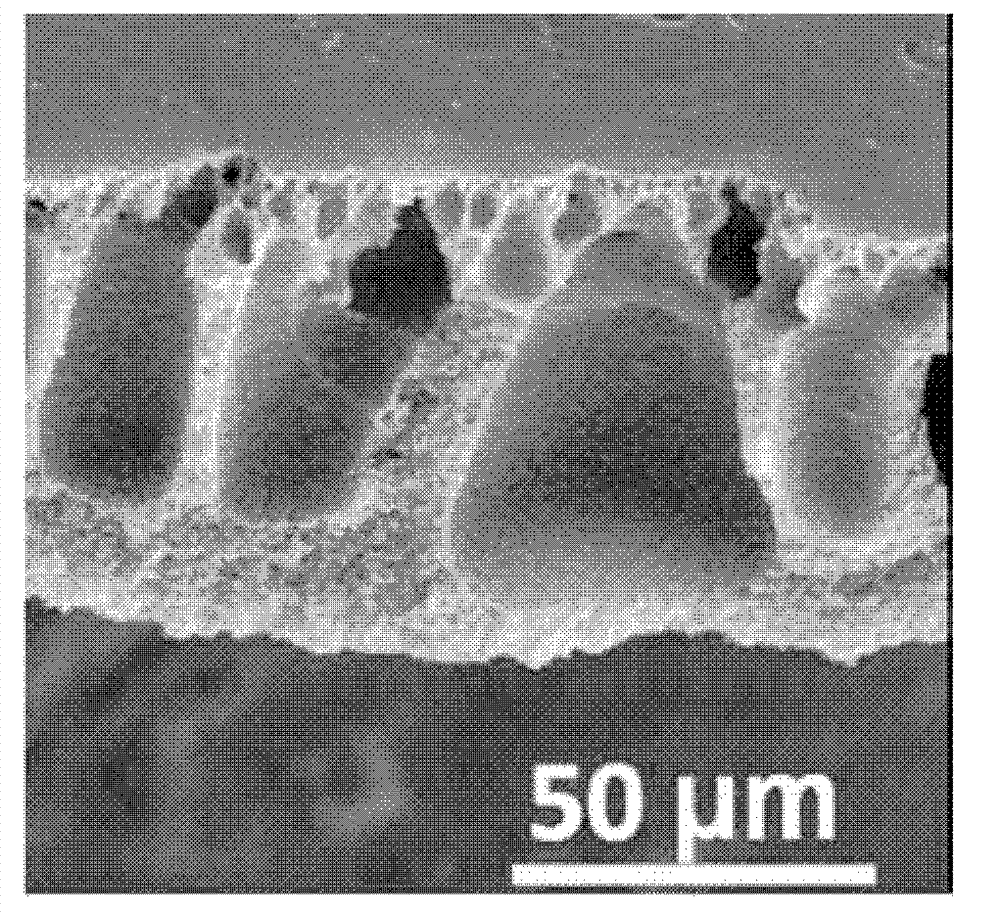

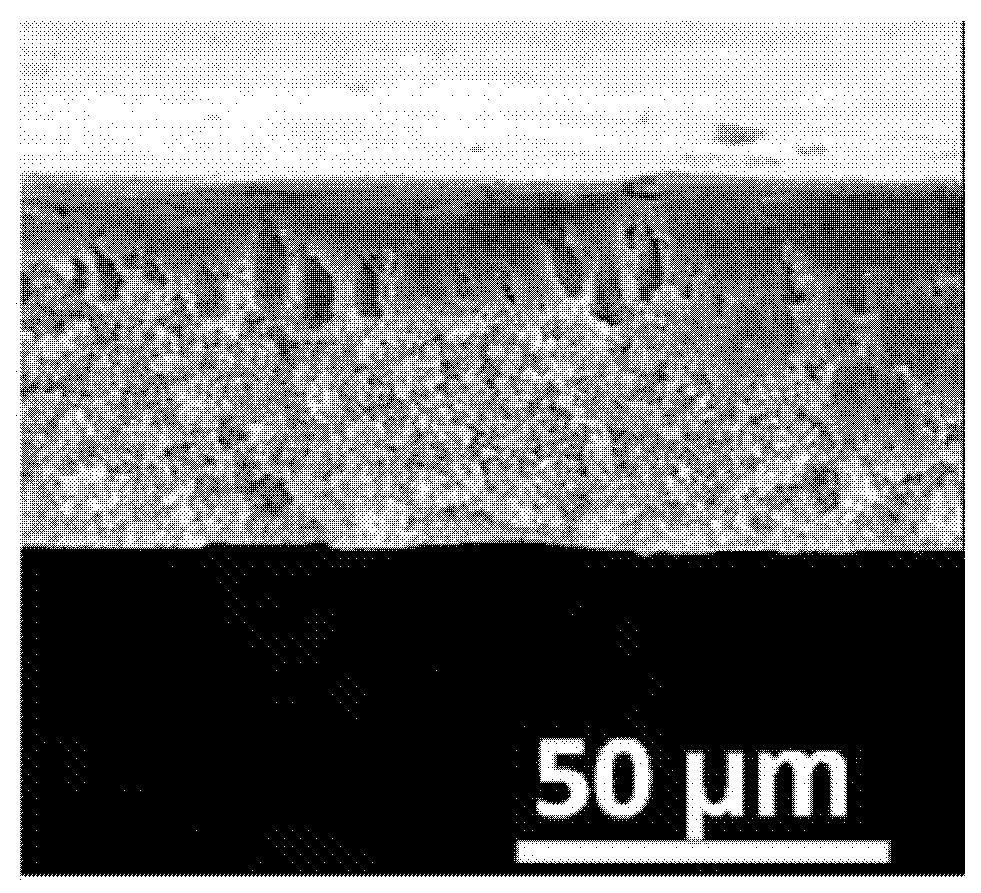

[0034] 4. Cast the casting solution prepared in step 3 into a liquid film on a flat plate and then immerse it in the coagulation bath for solvent and non-solvent exchange to realize the phase inversio...

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment is different from Embodiment 1 in that the nanomaterial in step 1 is silicon dioxide, titanium dioxide, acidified carbon nanotubes or clay. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the preparation method of acidified carbon nanotubes is: disperse carbon nanotubes with a mass percentage of 0.1% to 5% in mixed acid and stir for 2h to 48h to obtain acidified carbon nanotubes. Nanotubes; wherein the mixed acid is prepared from concentrated sulfuric acid with a mass percent concentration of 98% and concentrated nitric acid with a mass percent concentration of 65% in a volume ratio of 3:1. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com