A kind of fast drying equipment for electromechanical textile

A rapid drying and spinning technology, applied in textiles and papermaking, textile material processing, textile material drum processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate understanding of the present invention, the present invention will be described more fully hereinafter with reference to the related drawings. The preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention may be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that a thorough and complete understanding of the present disclosure is provided.

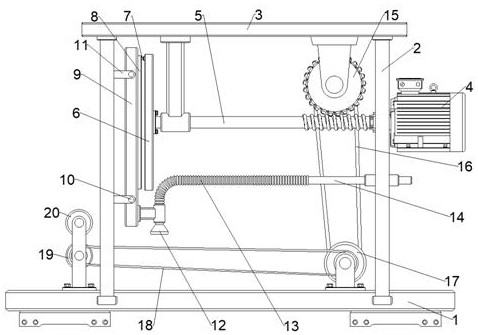

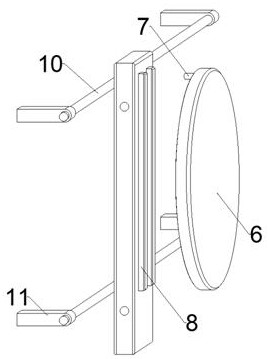

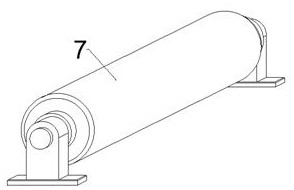

[0019] see Figures 1 to 3 , in the embodiment of the present invention, a kind of fast drying equipment for electromechanical textile, comprising a base plate 1, a support frame 2 fixed on both sides of the base plate 1, and a mounting plate 3 fixed on the upper part of the support frame 2 on both sides; Wherein, a hot air nozzle 12 for moving and spraying hot air to the cloth on the bottom plate 1 is movably arranged above the bottom plate 1 , the hot air nozzle 12 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com