Large-span railway steel bridge end telescopic device

A telescopic device and large-span technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as lack of design and application cases, and achieve the effect of convenient follow-up maintenance, easy installation and laying, and convenient follow-up maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

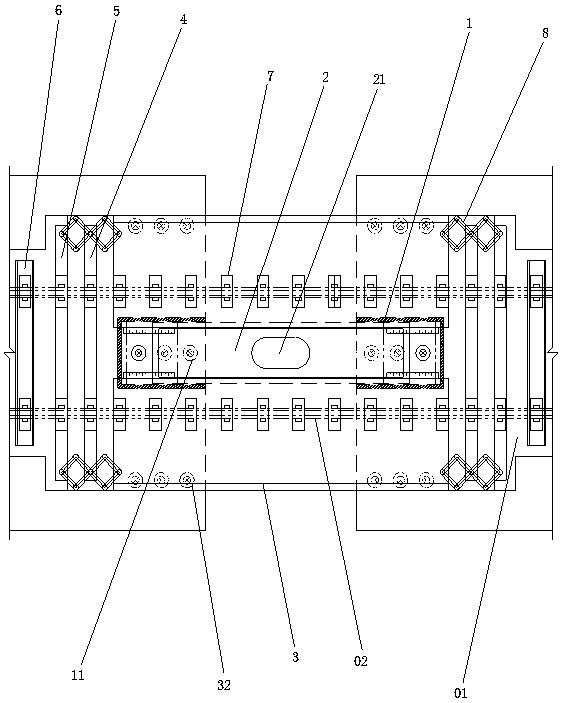

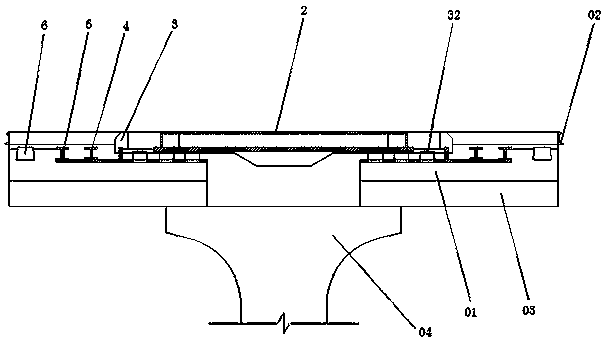

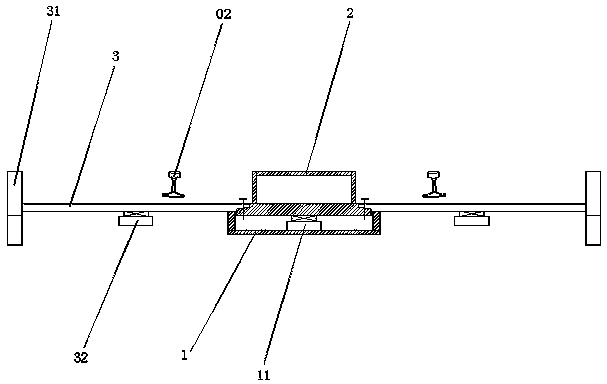

[0030] Such as Figures 1 to 3 As shown, the present invention is suitable for a large-span railway steel bridge end telescopic device with super large telescopic displacement, including a guide chute 1, a middle transition plate 2, a side transition plate 3, a movable steel sleeper 4, a fixed steel sleeper 5, and a concrete switch sleeper 6 , small resistance fastener 7 and connecting rod telescoping mechanism 8.

[0031] The guide chute 1 is matched and installed on the upper part of the ballast bed 01 of the railway steel bridge. The inner groove bottom of the guide chute 1 is evenly provided with a plurality of slide plate type intermediate transition plate vibration damping and damping supports 11 along the length direction. The guide chute 1 is provided with a telescopic sign 12 at the bottom of the inner groove at both ends.

[0032] The intermediate transition plate 2 is matched and fixedly installed on the upper part of the guide chute 1 and the bottom is matched and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com