Rotatable polycrystalline diamond composite tooth and drill bit with same

A technology of polycrystalline diamond and composite teeth, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of poor impact resistance and short service life of polycrystalline diamond composite teeth, so as to avoid premature failure, Prevents severe wear and improves utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

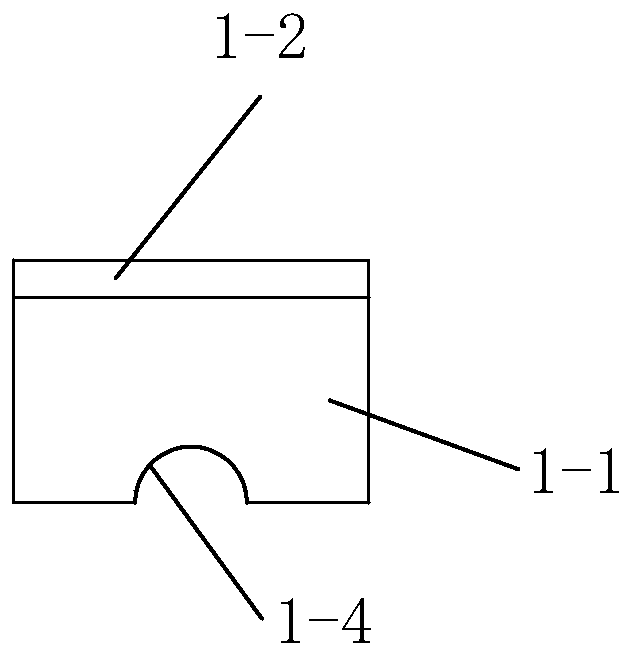

[0031] A rotatable polycrystalline diamond composite tooth 1 is mainly composed of a cemented carbide matrix 1-1 and a polycrystalline diamond layer 1-2. The polycrystalline diamond layer 1-2 is compounded on the upper surface of the cemented carbide substrate 1-1, and the two are sintered together by means of high temperature and high pressure. The shape of the upper surface of the polycrystalline diamond layer 1-2 is designed according to needs, such as a plane, arc or helmet-shaped surface. The lower surface of the cemented carbide substrate 1-1 can be designed as required, such as a plane or an arc. In a preferred embodiment of the present invention, for convenience of description, the upper surface of the polycrystalline diamond layer 1-2 and the lower surface of the cemented carbide substrate 1-1 are both planes.

[0032]In order to realize the rotation of the polycrystalline diamond composite tooth 1, the center of the lower surface of the cemented carbide substrate 1-...

Embodiment 2

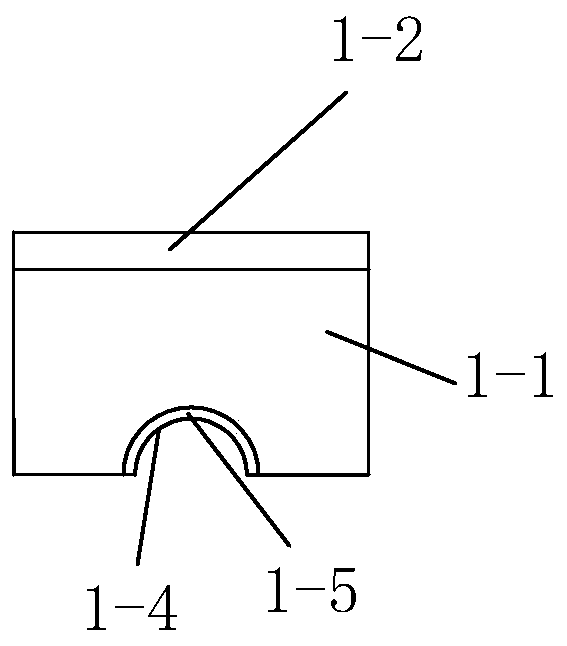

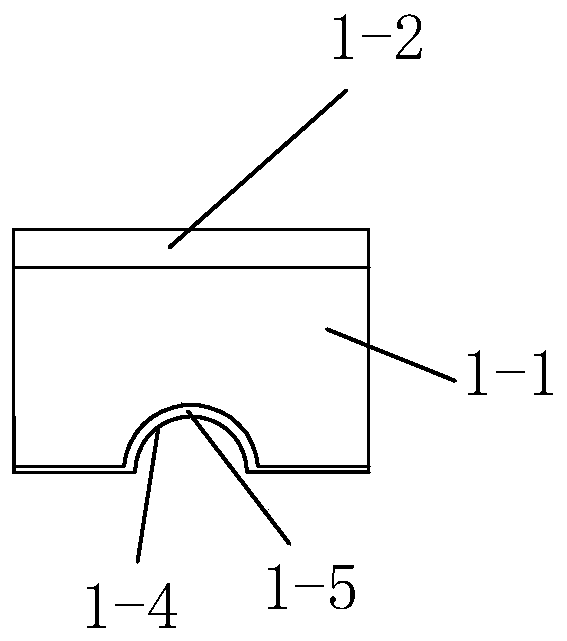

[0036] A rotatable polycrystalline diamond composite tooth 1 is mainly composed of a polycrystalline carbide matrix 1-1, a polycrystalline diamond layer 1-2 and a wear-resistant layer 1-3. The polycrystalline diamond layer 1-2 is compounded on the upper surface of the cemented carbide substrate 1-1, and the wear-resistant layer 1-3 is compounded on the lower surface of the cemented carbide substrate 1-1, and the three are sintered together by means of high temperature and high pressure. The shape of the upper surface of the polycrystalline diamond layer 1-2 is designed according to needs, such as a plane, arc or helmet-shaped surface. The lower surface of the wear-resistant layer 1-3 can be designed as required, such as a plane or an arc. In a preferred embodiment of the present invention, for convenience of description, the upper surface of the polycrystalline diamond layer 1-2 and the lower surface of the wear-resistant layer 1-3 are both planes.

[0037] In order to realiz...

Embodiment 3

[0040] see Figure 7-8 , a drill bit, including a drill bit body 2, N polycrystalline diamond composite teeth 1 and N metal balls 3.

[0041] The drill bit body 2 is substantially the same as the existing structure, that is, the drill bit body 2 is provided with N mounting holes 2-1 for the installation of the polycrystalline diamond composite teeth 1, and the number and size of the mounting holes 2-1 are the same as those of the polycrystalline diamond composite teeth. The size of tooth 1 matches. The shape of the bottom surface of the mounting hole 2-1 matches the shape of the bottom surface of the polycrystalline diamond composite tooth 1. For example, when the bottom surface of the polycrystalline diamond composite tooth 1 is convex arc-shaped, the bottom surface of the mounting hole 2-1 is also concave arc-shaped. ; If the bottom surface of the polycrystalline diamond composite tooth 1 is concave arc-shaped, the bottom surface of the mounting hole 2-1 is also convex arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com