Dual-pipe butting structure of solar energy heat collecting pipe and method

A technology of solar collector tubes and inner tubes, applied in the fluid circuit connection of solar collectors, parts of solar collectors, solar collectors, etc., can solve problems such as stress concentration, reduce damage and improve efficiency , Reduce the effect of installation accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

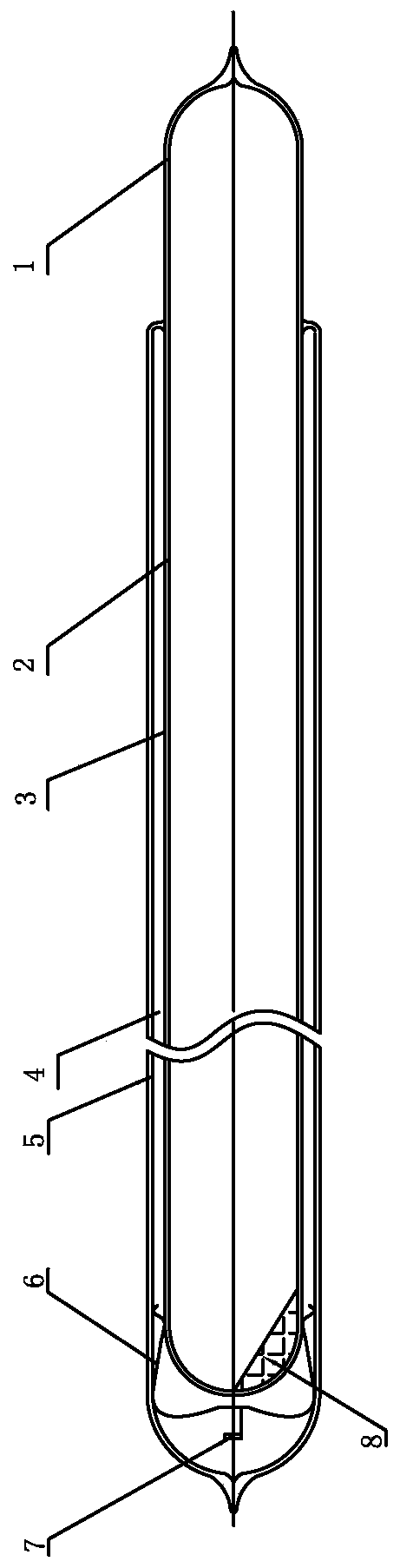

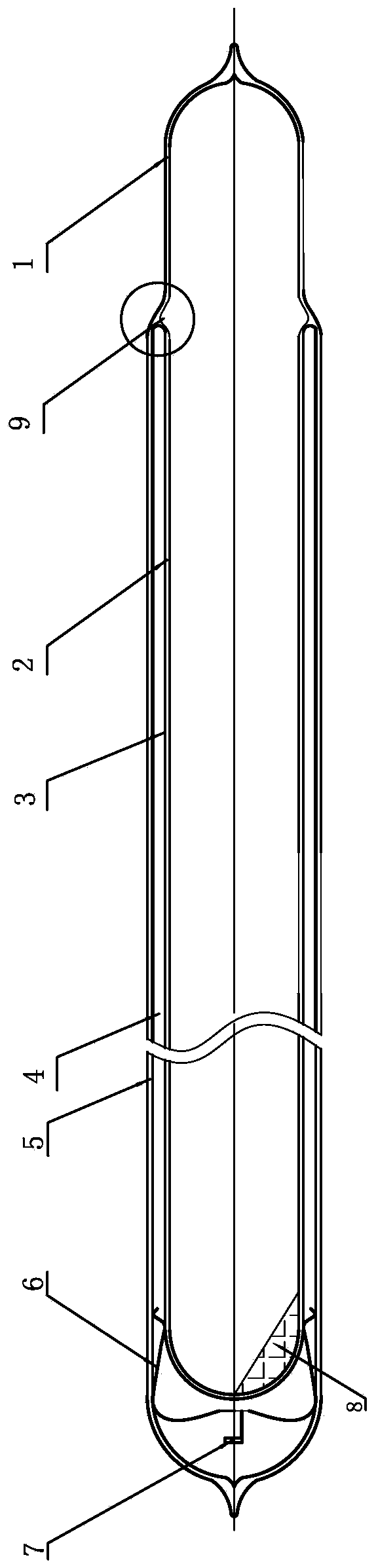

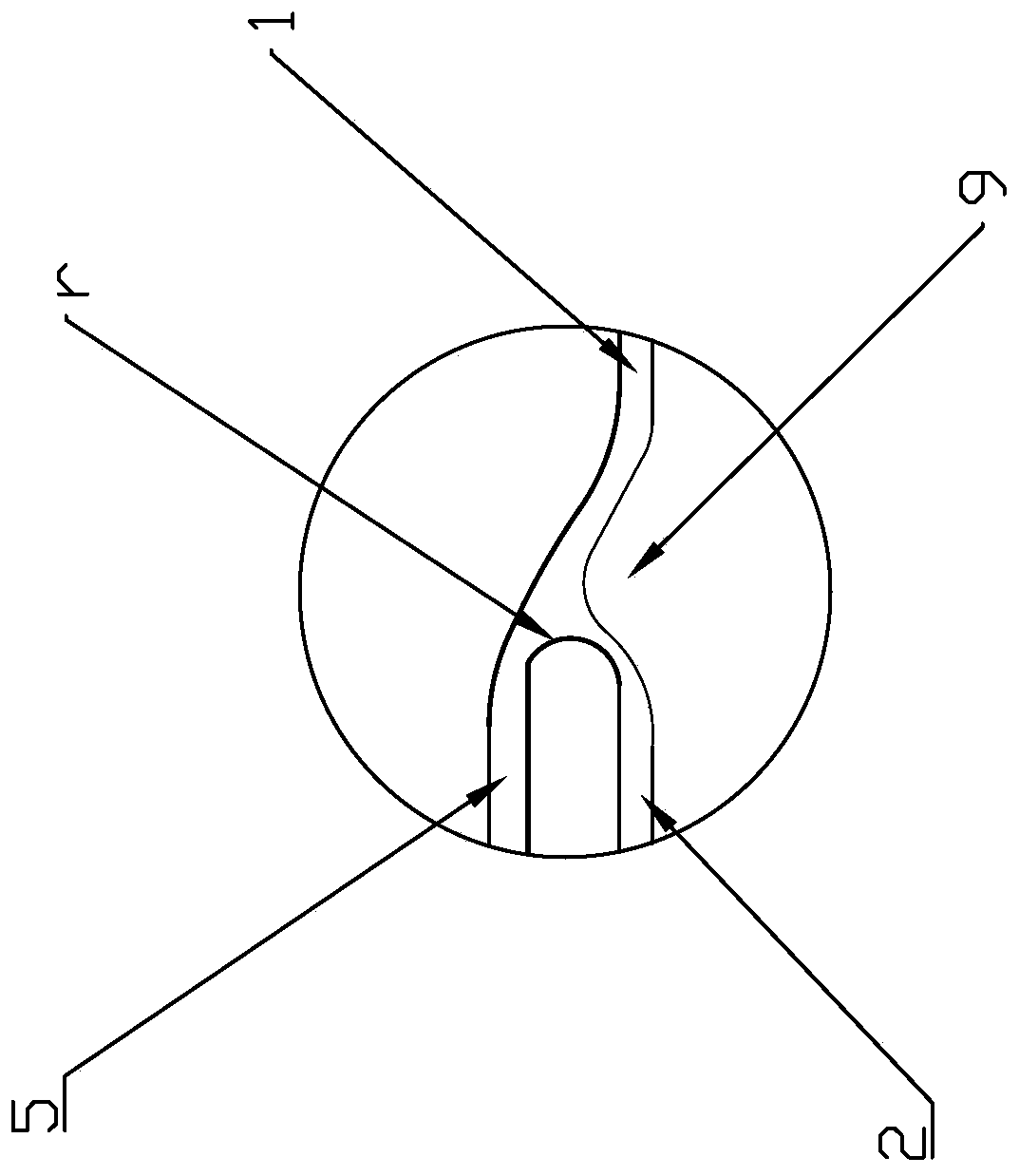

[0027] Such as figure 2 As shown, the present invention provides a kind of all-glass heat pipe vacuum heat collection tube, which has a double-tube butt joint structure composed of an inner tube (including a condensation section 1 and a heat absorption section 2) and a cover glass tube 5, and the round head of the heat absorption section 2 It is fixed with a bracket 6 between the cover glass tube 5, and a getter 7 is arranged on the bracket 6. There is a vacuum interlayer 4 between the heat-absorbing section 2 and the cover glass tube 5, and the outer wall of the heat-absorbing section 2 has a selective absorption coating 3. The inside of the heat-absorbing section 2 and the condensing section 1 constitutes a working medium chamber, and the working medium chamber is evacuated and placed with a liquid working medium 8. The volume ratio of the liquid working medium 8 to the volume of the working medium chamber is 2-1000 five out of five.

[0028] In order to reduce or even eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com