Standoff panel thermal protection system and method of making same

A thermal protection and panel technology, which is applied to chemical instruments and methods, systems for aerospace vehicles returning to the earth's atmosphere, thermal protection devices for aerospace vehicles, etc., can solve problems such as the weight of metal honeycomb panels, increase the strength-to-weight ratio, increase Structural efficiency, effect of increasing ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Clause 1. A standoff panel thermal protection system, said standoff panel thermal protection system comprising:

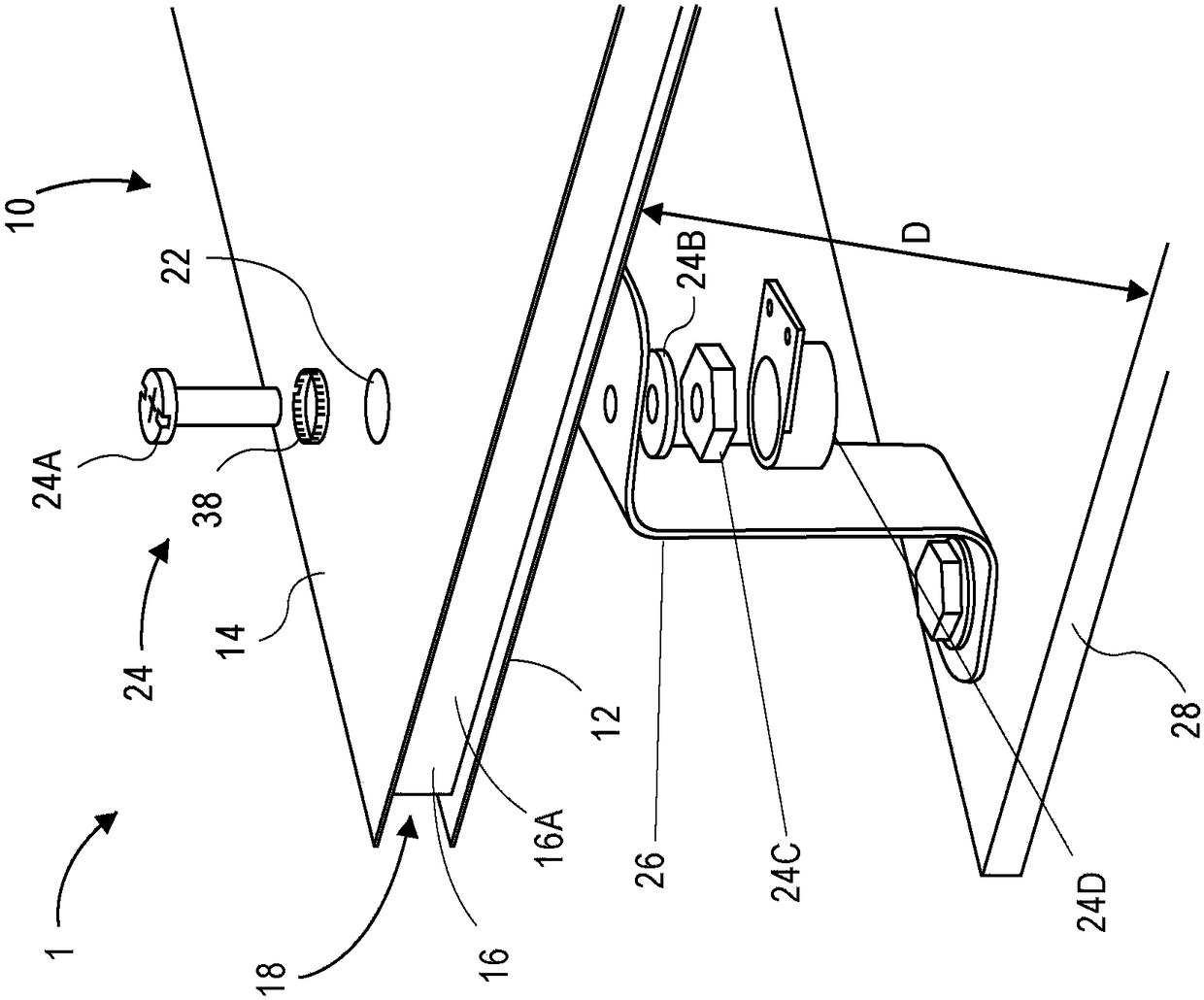

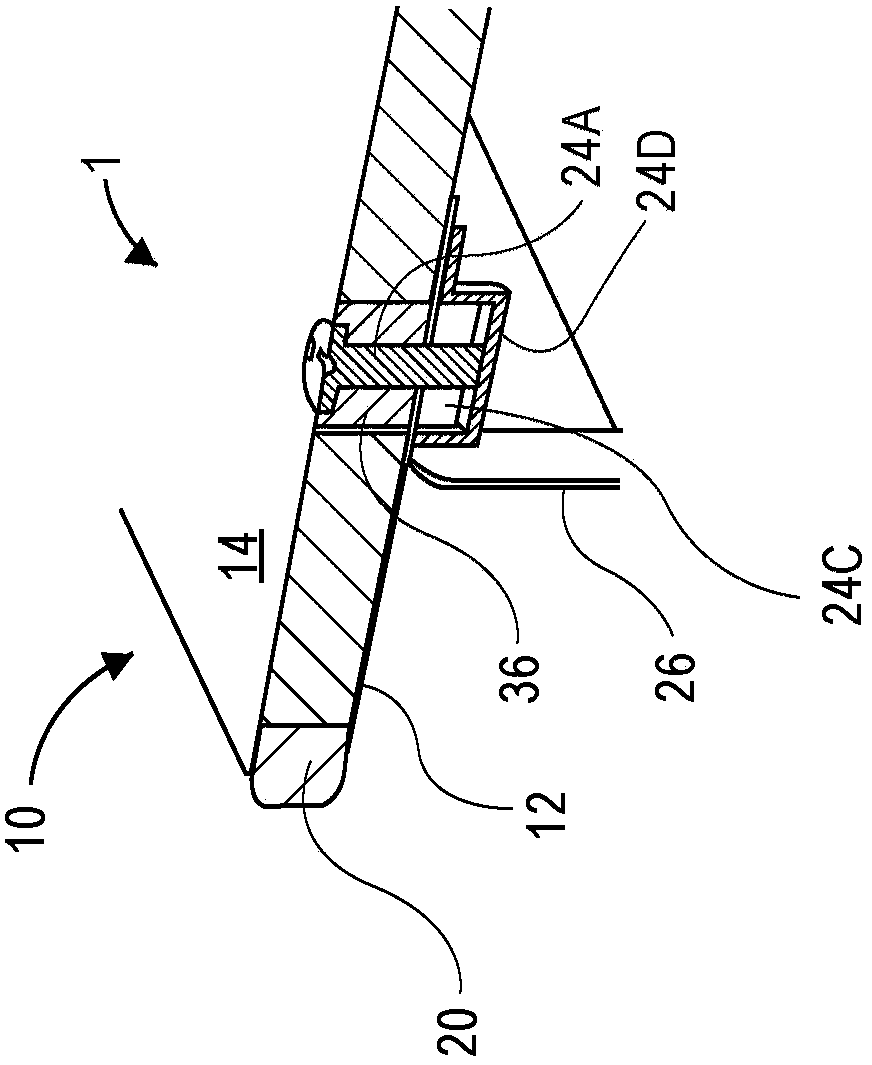

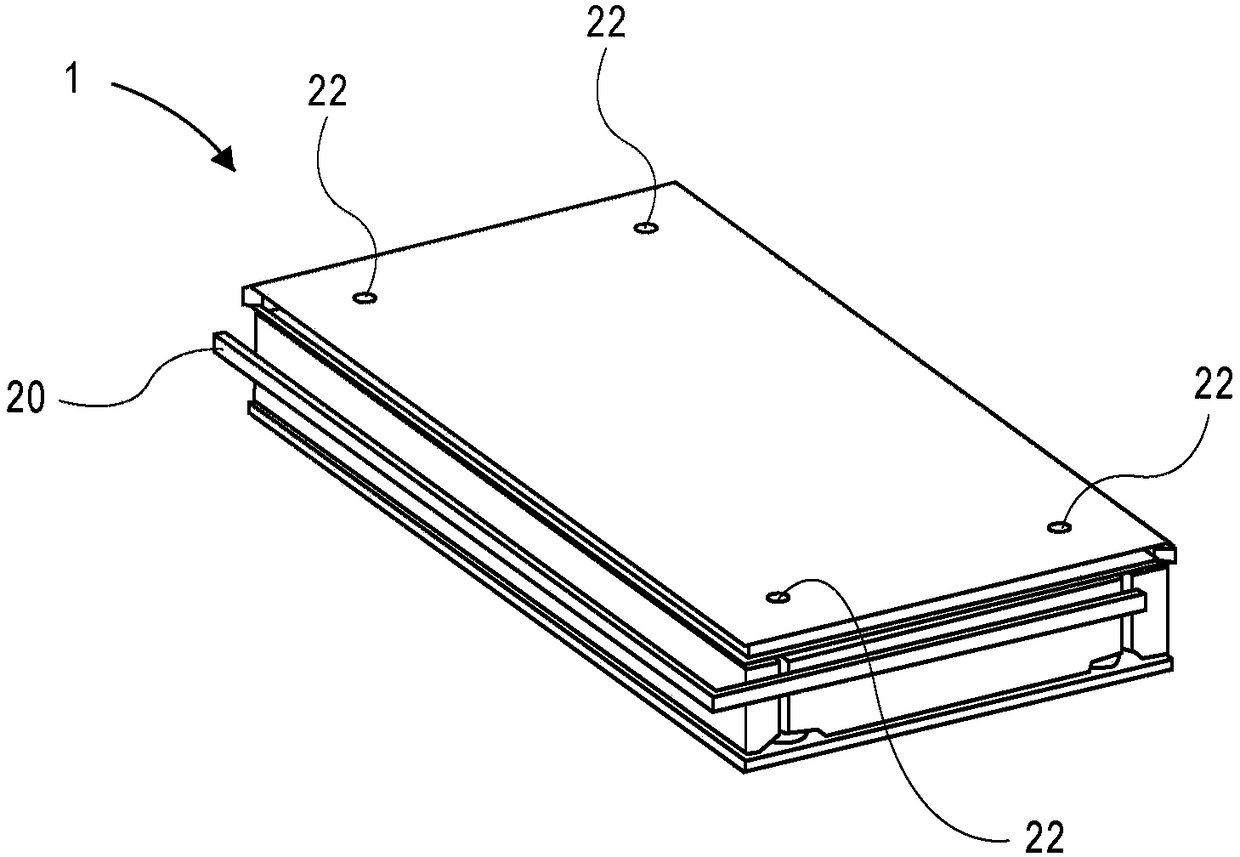

[0043] A sandwich panel comprising: a first ceramic matrix composite facing sheet and a second ceramic matrix composite facing sheet positioned between the first ceramic matrix composite facing sheet and the second ceramic matrix composite facing sheet between a ceramic matrix composite core, said ceramic matrix composite core having a perimeter, said first ceramic matrix composite facing sheet and said second ceramic matrix composite facing sheet extending beyond said perimeter to a gap around the ceramic matrix composite core formed between the first ceramic matrix composite facing sheet and the second ceramic matrix composite facing sheet; and a plurality of holes formed through the sandwich panel; positioned a soft commodity seal in the gap; a plurality of spacer members; a plurality of stand-off brackets; and a plurality of fasteners positionable throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com