Temperature measuring device for main bus of metal-enclosed switch

A temperature measuring device, metal-enclosed technology, applied in measuring devices, thermometers, measuring heat, etc., can solve the problems of high voltage, unable to meet the requirements of wireless signal transmission and insulation safety distance, etc., to ensure sealing and improve use safety. Reliability, clever design and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

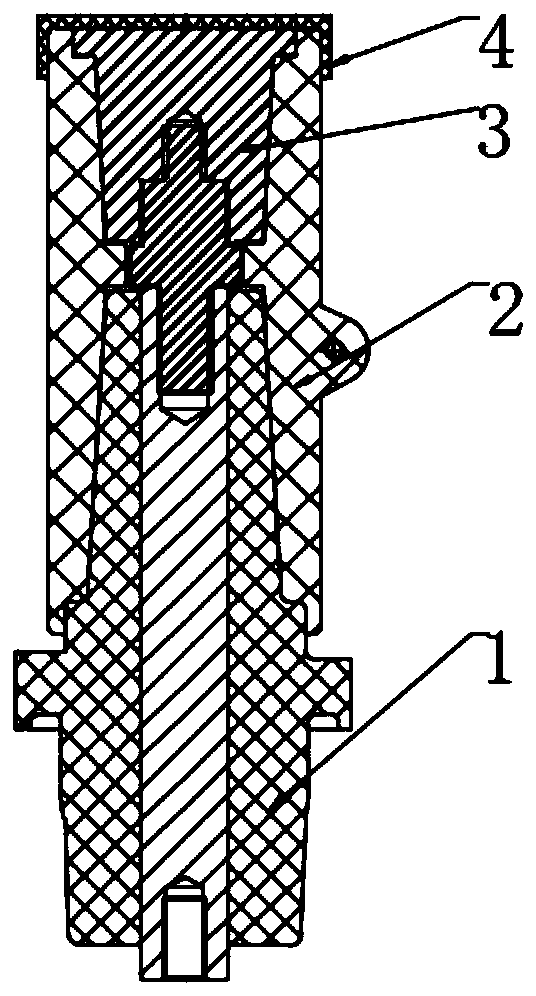

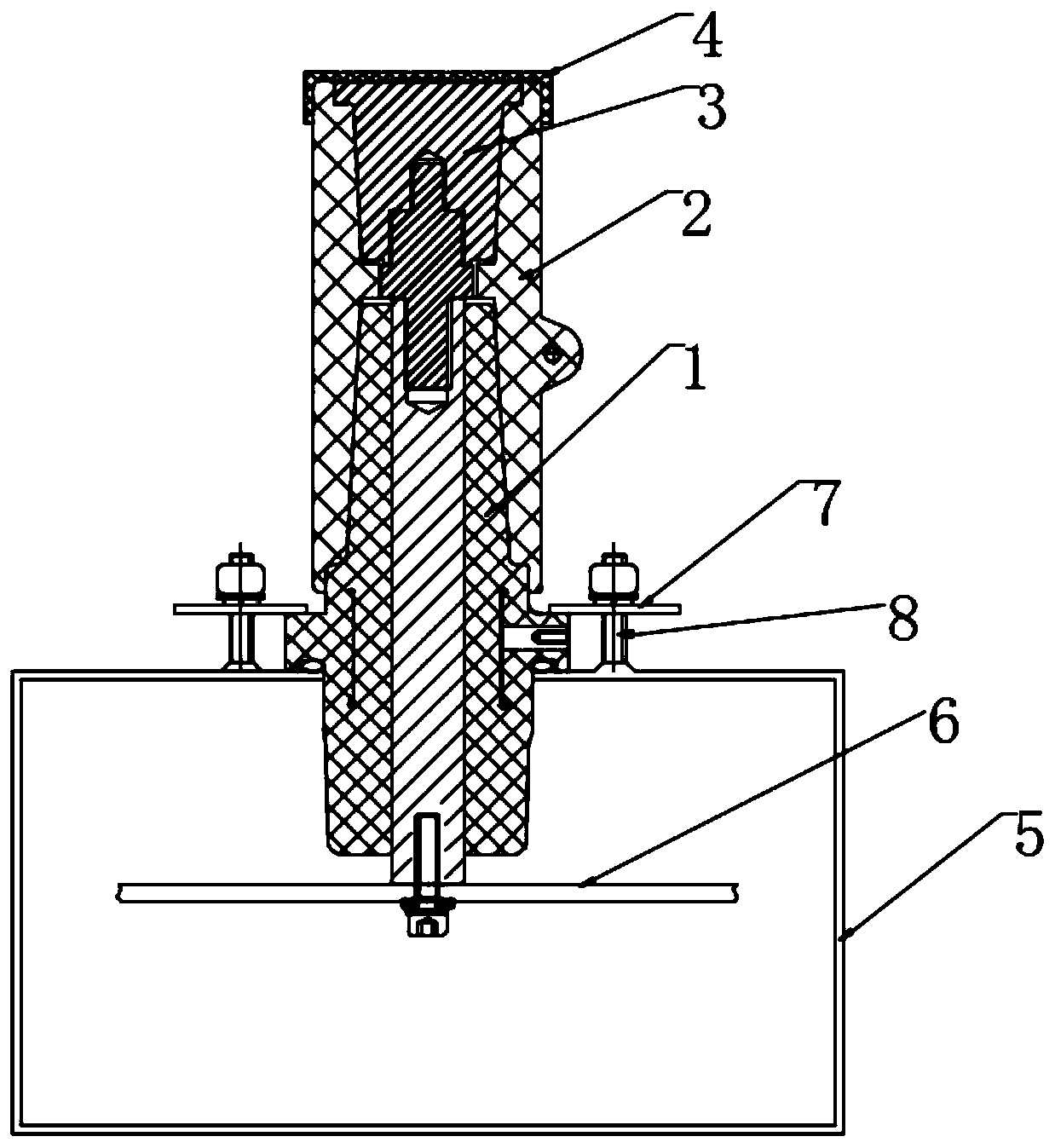

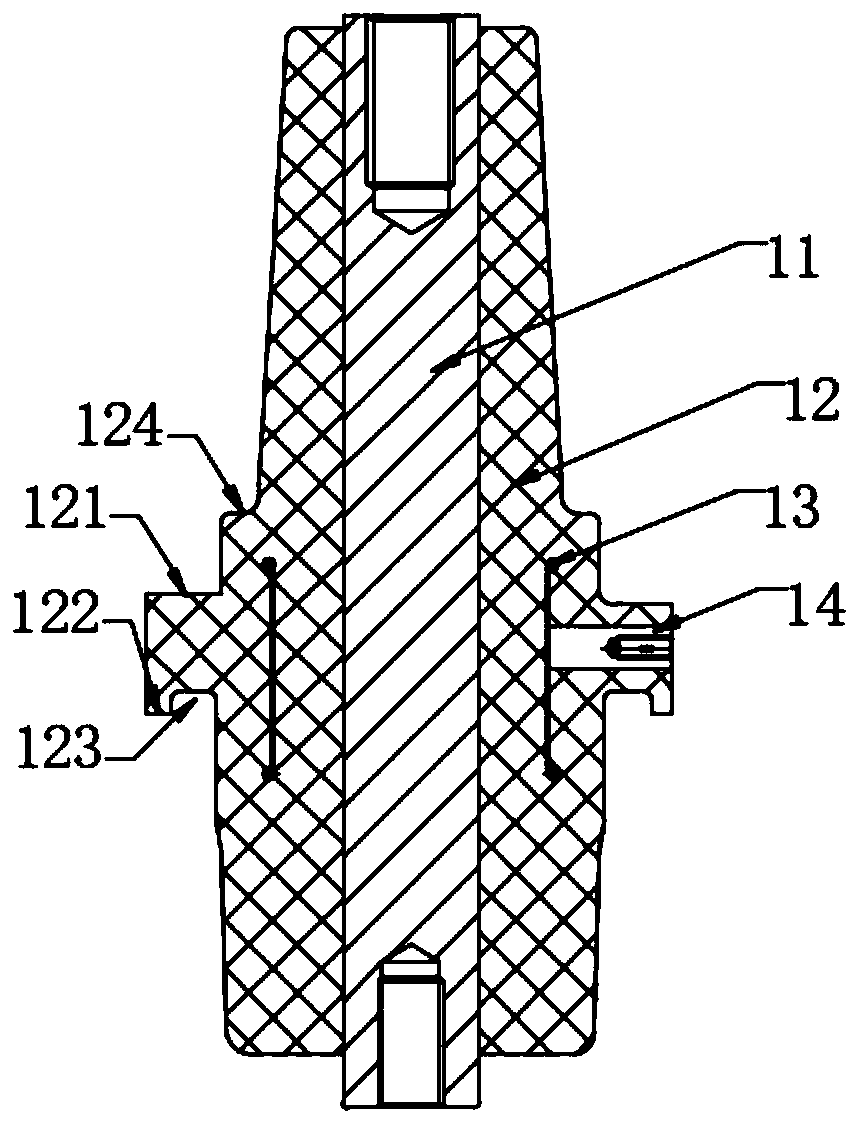

[0037] The embodiment is basically as Figure 1 to Figure 6 As shown: this embodiment provides a metal-enclosed switch main bus temperature measuring device, the temperature measuring device includes a bushing 1, an insulating boot 2, a temperature measuring plug 3 and a protective cap 4, and the temperature measuring device passes through the bushing 1 is installed at the opening of the metal-sealed switch box body 5 and ensures a sealed connection; specifically, a first conductor 11 passing through both ends of the bushing 1 is provided inside the bushing 1, and the bushing 1 is formed around the first conductor. Protective layer 12, the design of the protective layer 12 can prevent the first conductor 11 from being damaged by mechanical or heat, the lower end of the first conductor 11 is fixedly connected with the main bus bar 6 in the metal-sealed switch, and its upper end passes through the bushing 1 and connects with the The temperature measuring plug 3 is fixedly connec...

Embodiment 2

[0047] Embodiment 2 is basically the same as Embodiment 1, the difference is: please combine figure 1 , 4 and Figure 5 As shown, this embodiment provides a temperature measuring device for the main bus bar 6 of a metal-enclosed switch. In order to facilitate the installation of the bushing 1 and the temperature measuring plug 3 in the insulating boot 2, the insulating boot 2 provided by this embodiment has The hollow structure of the tapered inner cavity allows the bushing 1 and the temperature measuring plug 3 to be respectively inserted into the tapered inner cavity at both ends of the insulating boot 2 and matched therewith. Furthermore, a step extending along the direction of the above-mentioned boss is also provided on the outer wall of the sleeve 1, and a third stepped surface 124 is formed. The first mating surface 212 that matches the three stepped surfaces 124; at the same time, a raised portion extending outward is provided on the temperature measuring plug 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com