Naan (crusty pancake) maker

A technology of soot and drum, applied in the field of naan making equipment, can solve the problems of human health damage, high work intensity, and no consideration of the work intensity of the naan beater, and achieves the effect of ensuring variety and quality, reducing labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

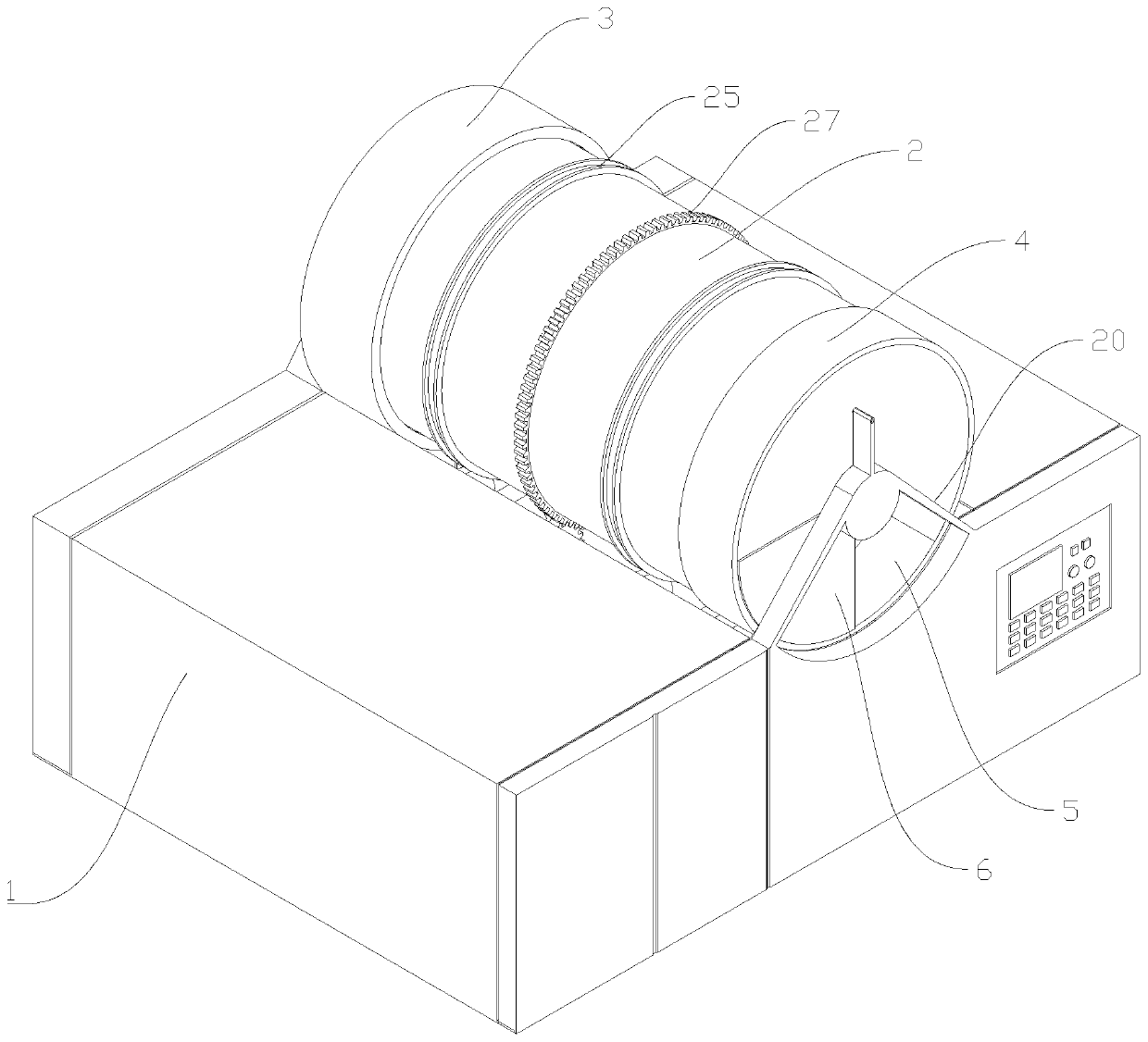

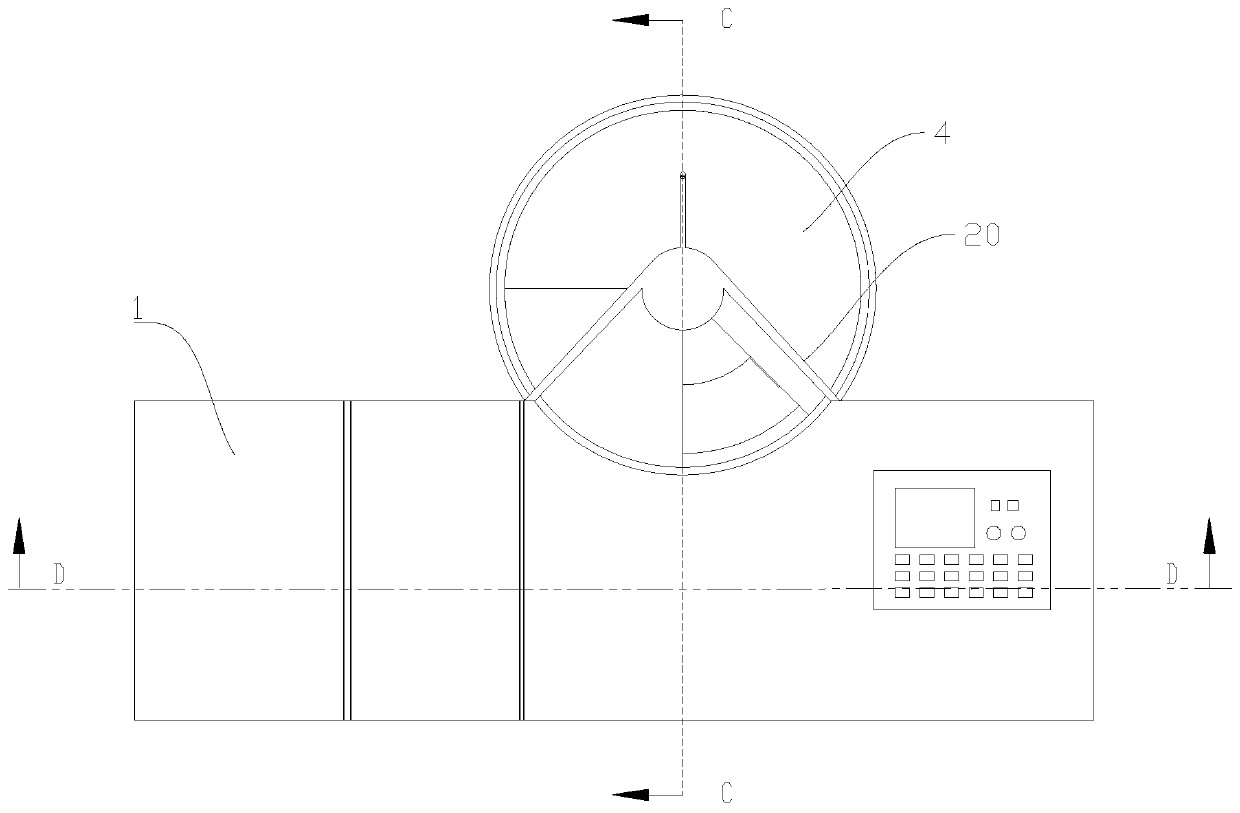

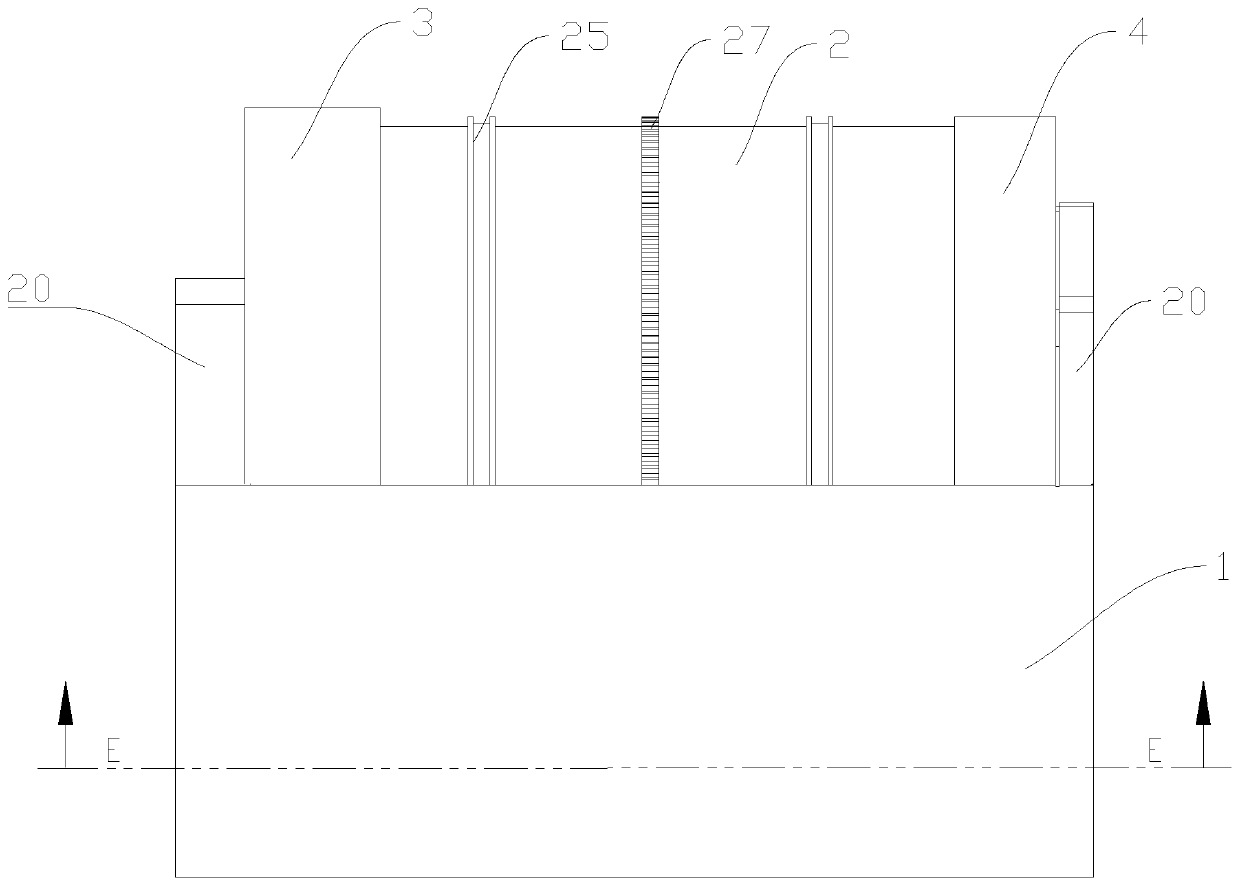

[0040] Such as figure 1 The shown nang making machine comprises a horizontally arranged casing 1 and a cylindrical drum 2, a dust cover 3 and a fiberglass cover 4, and the drum 2, the dust cover 3 and the fiberglass cover 4 are arranged horizontally, and the drum 2, the dust cover 3 and the FRP cover 4 are both hollow structures, the two ends of the drum 2 are connected to each other, one end of the fume cover 3 and the FRP cover 4 is a plugged end, and the other end of the fume cover 3 and the FRP cover 4 It is an open end, and the side of the blocking end of the glass fiber reinforced plastic cover 4 is provided with a pancake mouth 5, and the pancake mouth 5 is provided with a swing door 6 for opening or closing the pancake mouth, and the pancake mouth 5 is fan-shaped. Shape, at the same time one end of the swing door 6 is connected to the side of the glass fiber reinforced plastic cover 4 by pin shaft rotation, the open end of the said smoke cover 3 and the open end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com