Oxygen exchange equipment for aquaculture

A technology for aquaculture and equipment, applied in application, fish farming, animal husbandry, etc., can solve problems affecting the survival rate of aquatic products, affecting the service life, and low oxygen delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

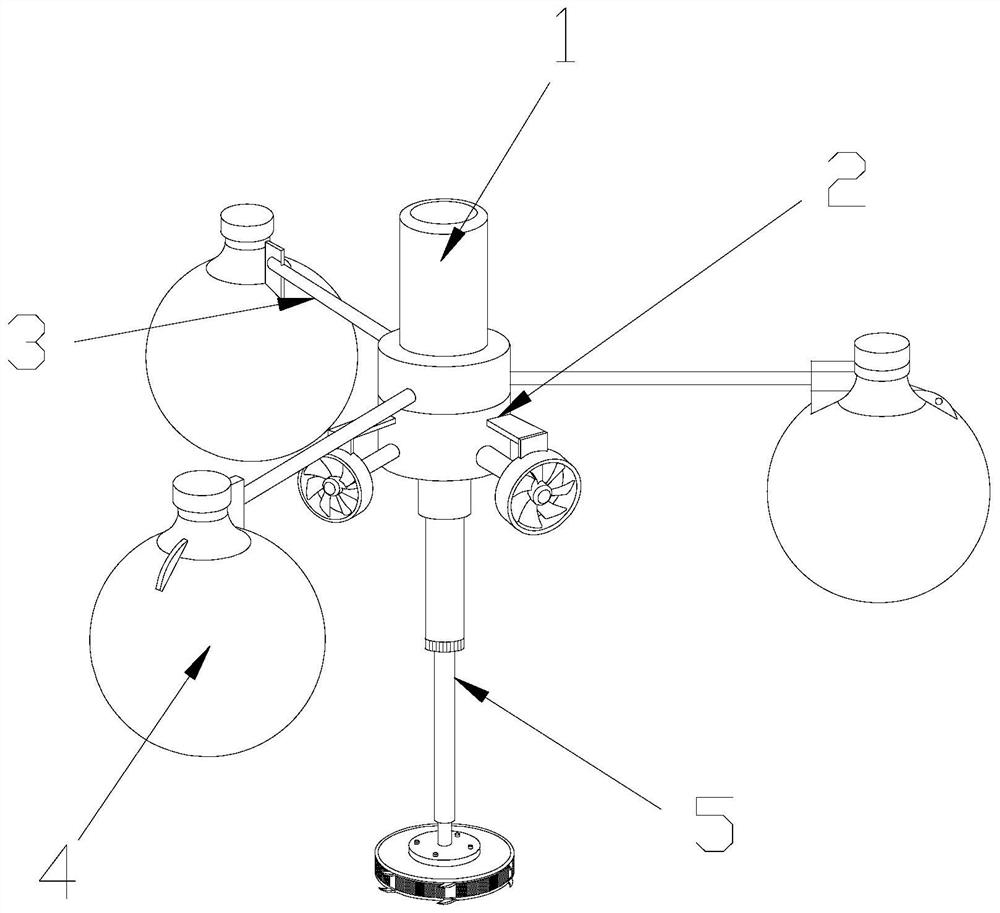

[0029] see Figure 1-Figure 7 , the present invention provides a kind of oxygen exchange equipment for aquaculture, its structure comprises oxygen generator 1, propulsion device 2, strut 3, floating ball 4, oxygen exchange mechanism 5, described propulsion device 2 top is installed with oxygen generator Machine 1, the surface of the propulsion device 2 is equidistantly provided with three struts 3, one end of the propulsion device 2 and the struts 3 is fixedly connected, and the other end of the propulsion rod 3 is provided with a floating ball 4, The strut 3 and the floating ball 4 are movably connected, the bottom of the propulsion device 2 is provided with an oxygen exchange mechanism 5, and the propulsion device 2 and the oxygen exchange mechanism 5 are matched;

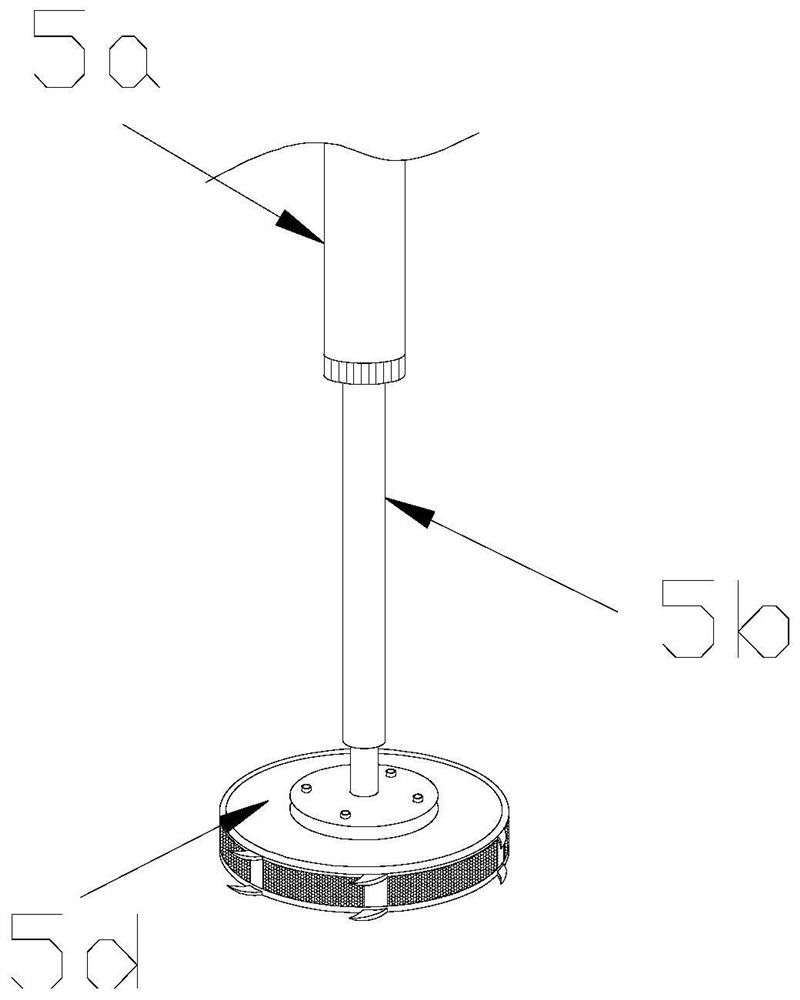

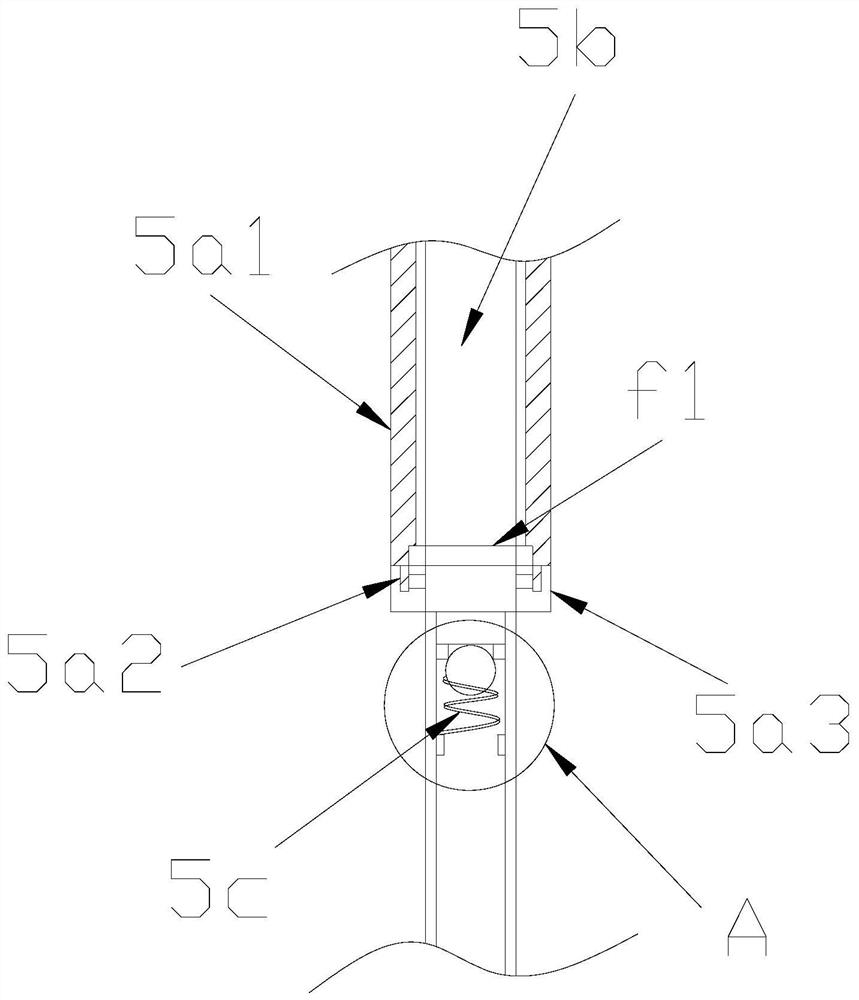

[0030] The oxygen exchange mechanism 5 is composed of a sealed telescopic adjustment mechanism 5a, a sliding connecting rod 5b, a backflow preventing mechanism 5c, and an oxygen releasing mechanism 5d. The seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com