Locking platform and machine tool system

A platform and compression plate technology, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as danger, pallet and worktable cannot maintain a fixed connection state, and pallets move away from the workbench, etc. , to achieve the effect of convenient combination, easy maintenance and replacement, and short stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

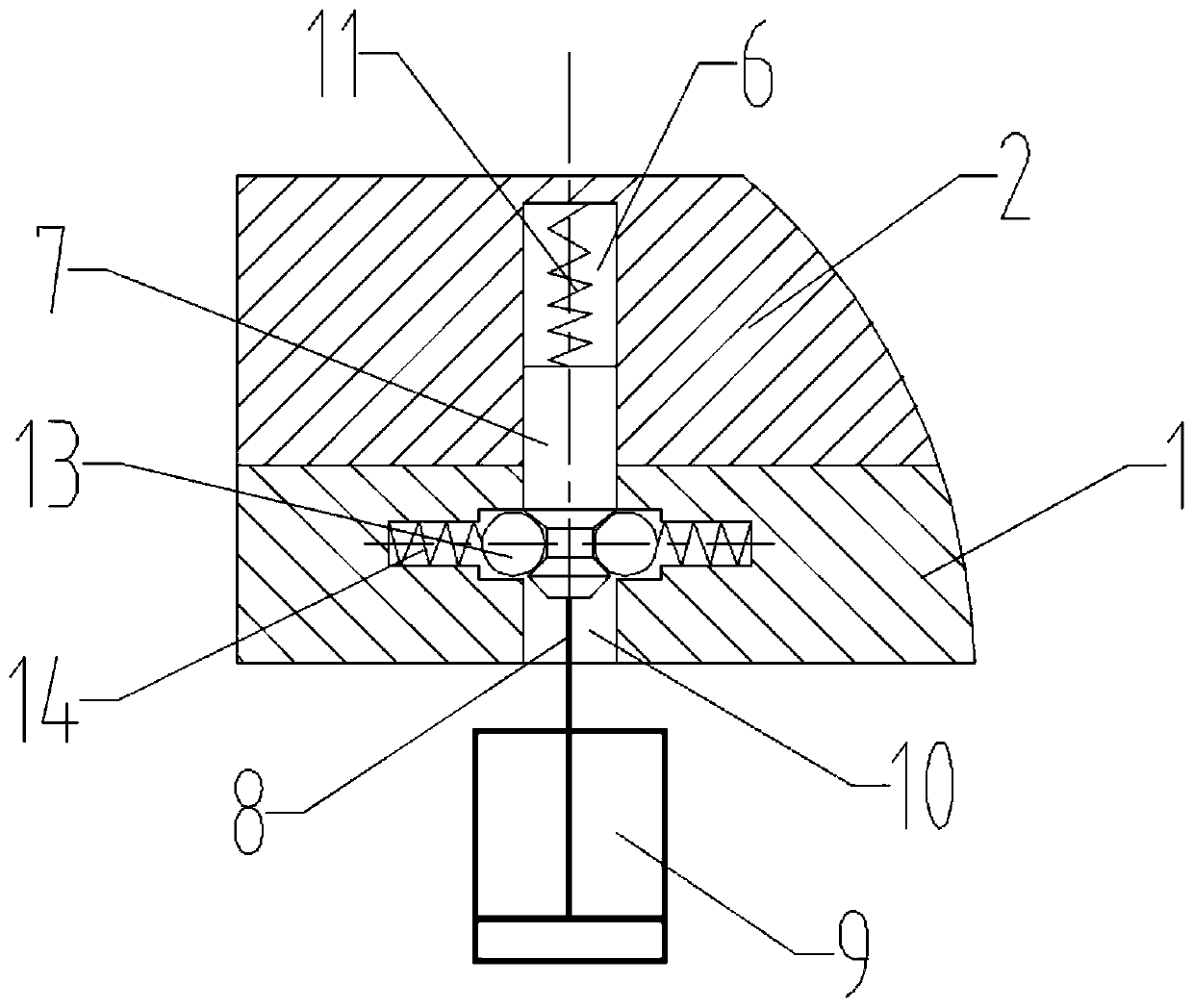

[0032] The locking platform in this embodiment, such as figure 1 with figure 2 As shown, it includes a pressing plate 1 , a tray 2 , an abutting assembly and an unlocking assembly 9 .

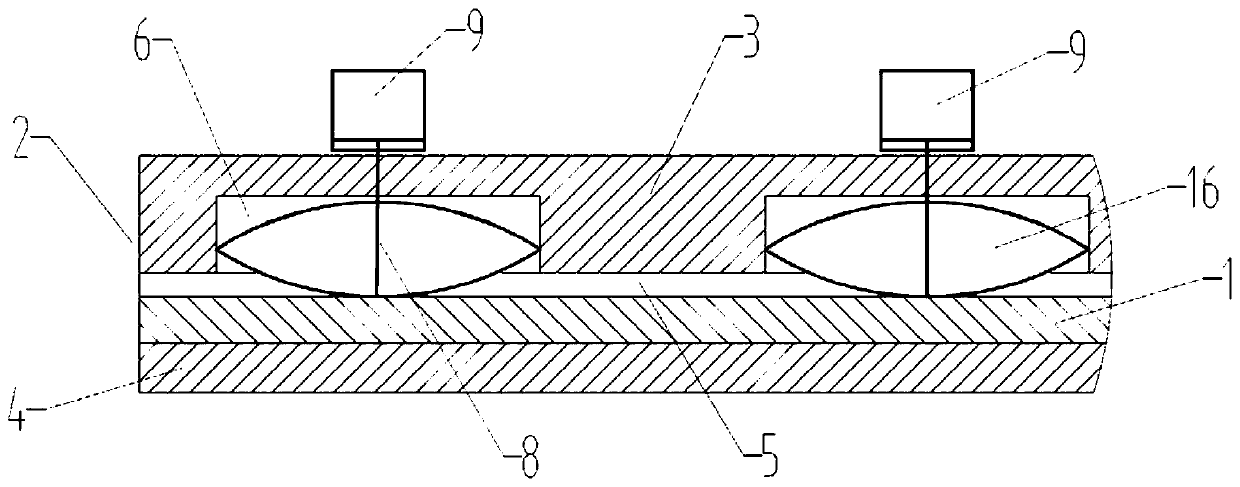

[0033] refer to Figure 5 , the tray 2 includes a Π-shaped main body 3, the lower end of the main body 3 is provided with an inwardly bent bent portion 4, and the main body 3 and the bent portion 4 are surrounded by a shape for the pressed plate 1 to move in and out. The cavity 5. In this embodiment, the cavity 5 is a regular rectangle, and of course it can also be of a different shape, such as an arc.

[0034] The first mounting groove 6 is arranged on the tray 2, and its groove opening faces the cavity 5; the second mounting groove 10 is arranged on the pressing plate 1, and the groove opening of the second mounting groove 10 faces the cavity. The groove opening of the first mounting groove 6 is described above.

[0035] The abutting assembly has a connecting piece 7 that extends out of...

Embodiment 2

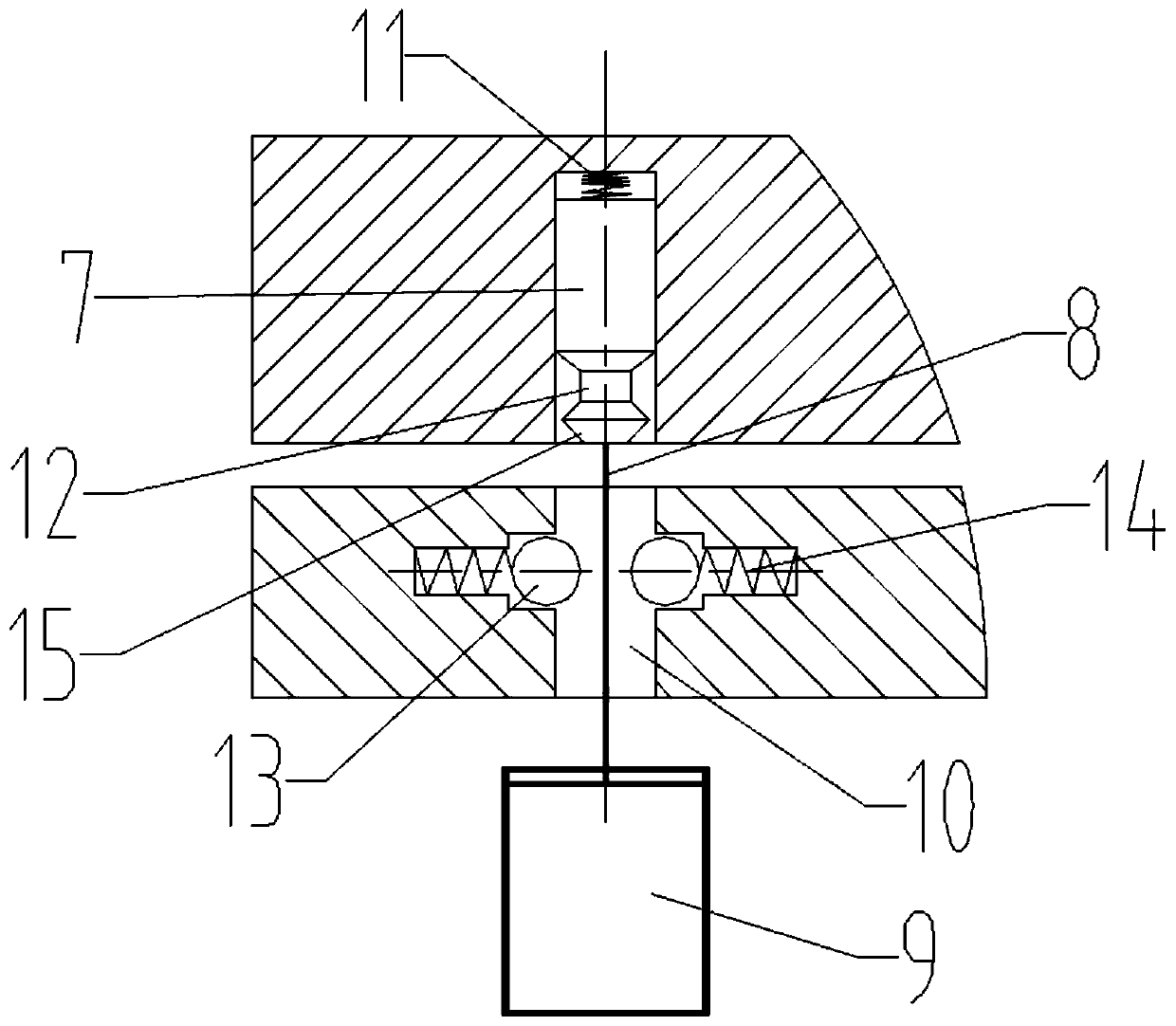

[0043] The locking platform in this embodiment, such as image 3 with Figure 4 As shown, the difference with Embodiment 1 is:

[0044] The first installation groove 6 is provided on the tray 2 , and its groove opening faces the cavity 5 . The abutting assembly has a connecting piece 7 that abuts against the pressing plate 1 after extending out of the first installation groove 6 in a free state, and the connecting piece 7 fixes the relative position of the tray 2 and the pressing plate 1 .

[0045] The connecting piece 7 is an elastic piece. Among them, because the disc spring 16 has the characteristics of large load, short stroke, small space required, convenient combination and use, easy maintenance and replacement, and high economical safety, therefore, in this embodiment, the disc spring 16 is used for the connecting part 7.

[0046] The tray 2 is provided with a through hole, and the unlocking assembly 9 has an output end 8 passing through the through hole of the tray...

Embodiment 3

[0049] The machine tool system in this embodiment has the locking platform in Embodiment 1 or Embodiment 2.

[0050] The pressing plate 1 and the unlocking assembly 9 of the locking platform are arranged on the machine tool, wherein the power source of the output end 8 of the locking assembly can be electric, pneumatic or hydraulic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com