Slag blowing machine

A slag blower and slag blower technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of difficult adjustment of the position of the workpiece and the blowing nozzle, and achieve simple structure, strong adaptability, and ease of use. the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

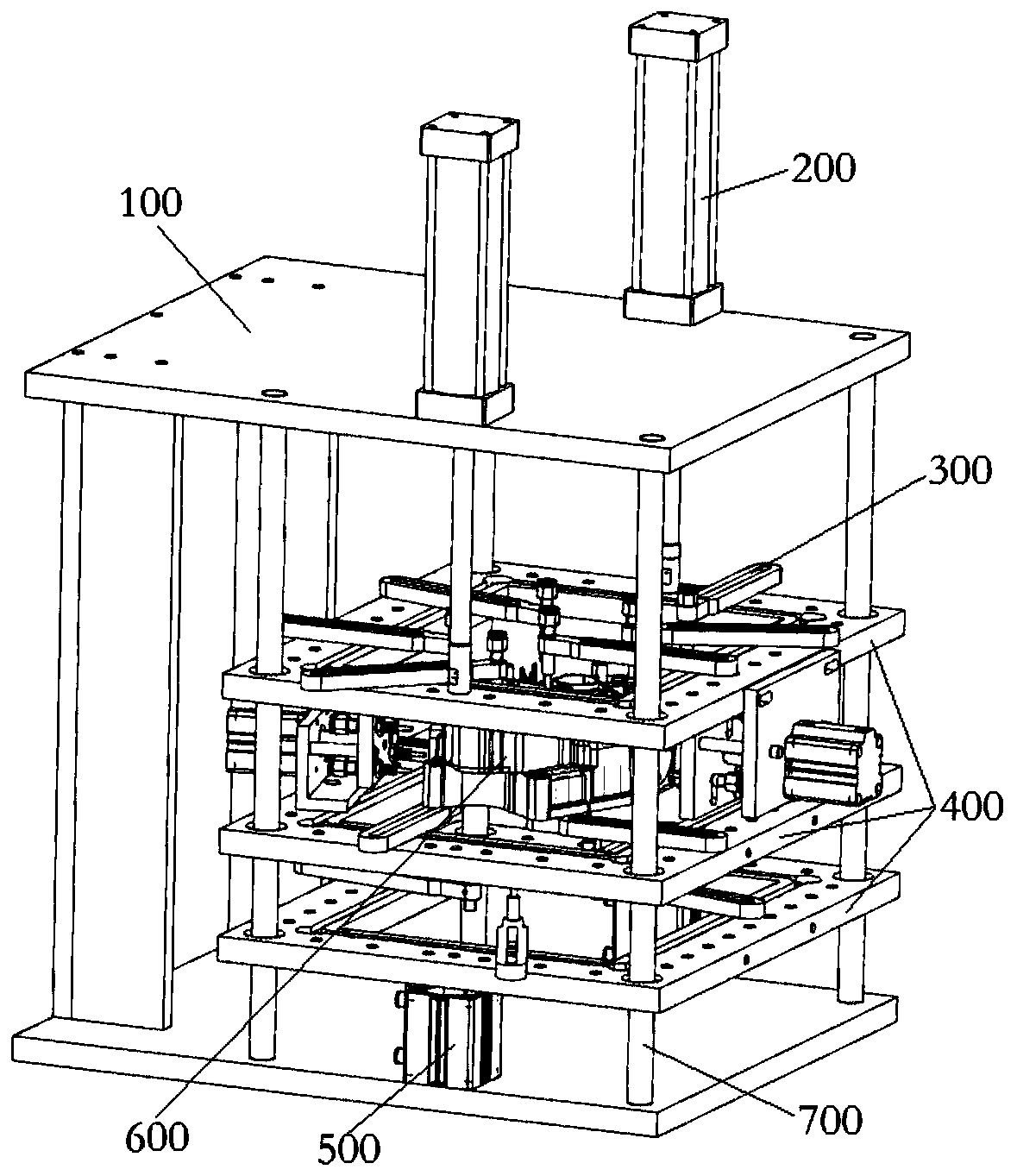

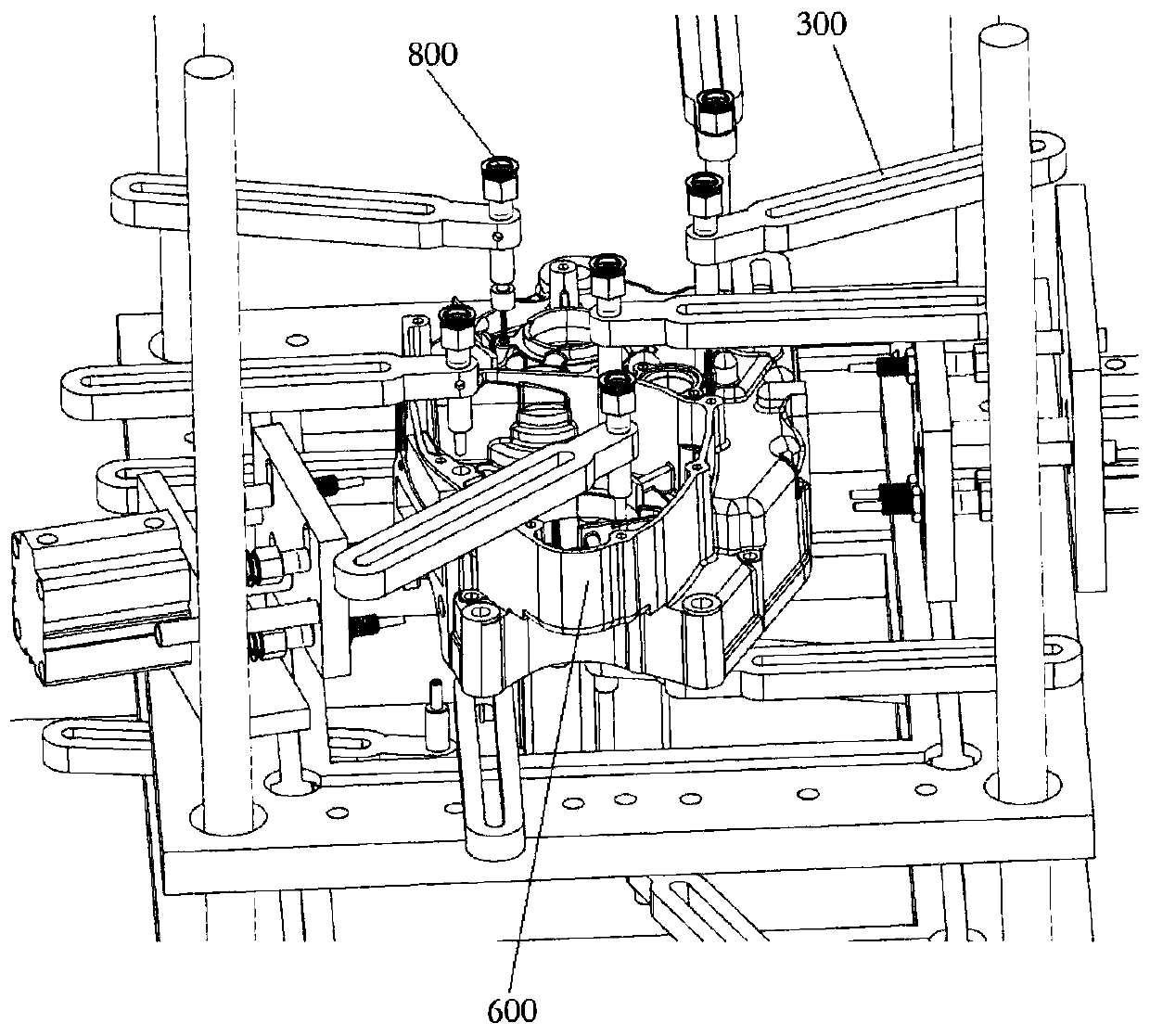

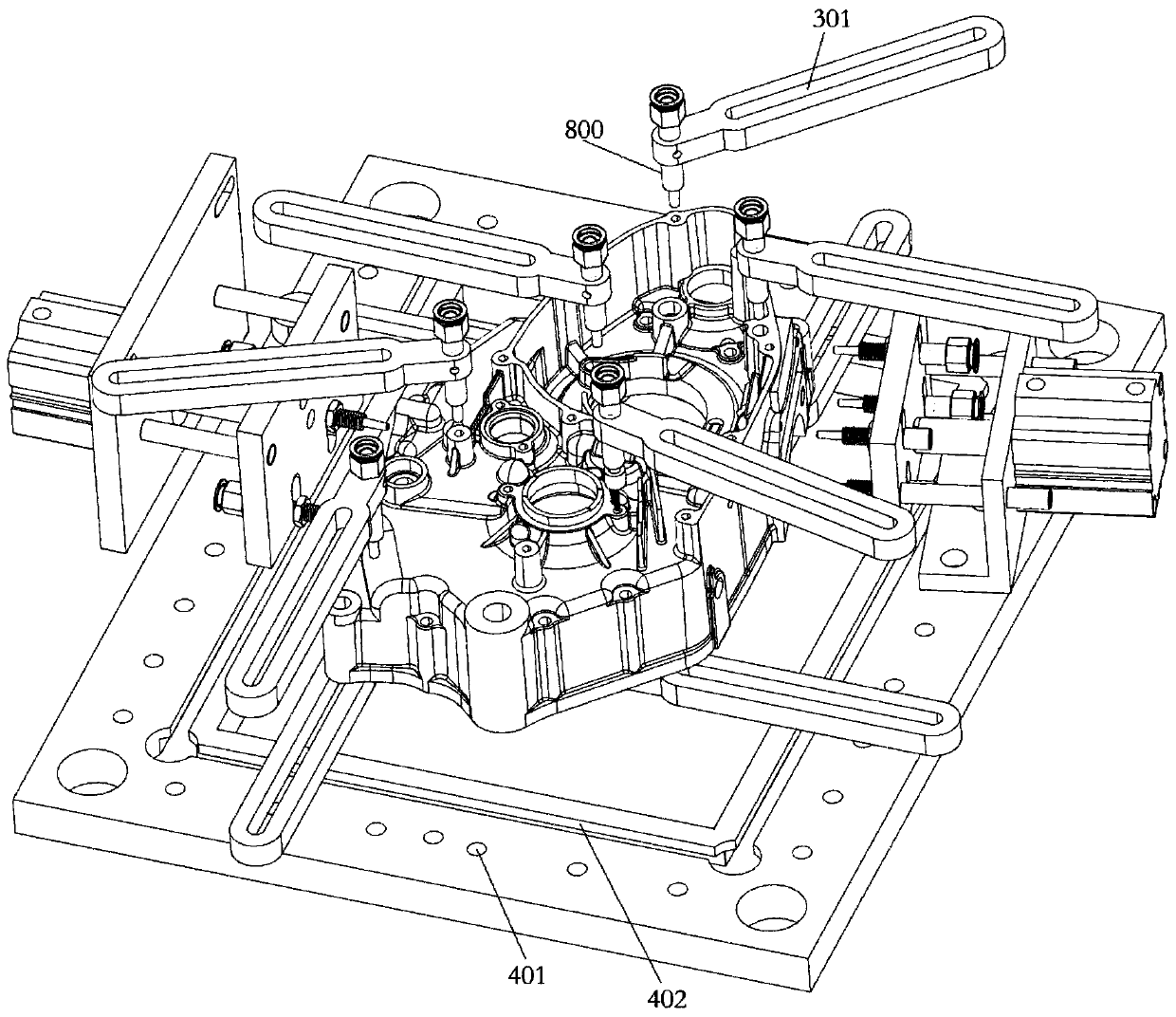

[0020] This embodiment describes a slag blowing machine, with figure 1 -4 as an example, this slag blowing machine includes a frame and a blowing nozzle 800 connected to a compressed air source, the blowing nozzle 800 is installed on the frame, and the frame is provided with a mounting plate for the workpiece 600 to be placed, so The frame includes three adjustment plates 400 arranged from top to bottom, all the adjustment plates 400 are connected by guide rods 700 vertically penetrating through its four corners, and the second adjustment plate 400 is fixed on the guide rods 700 as the installation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap