A birdcage bottom scraping equipment

A technology for scraping skin and bird cage, which is applied to bark, manufacturing tools, wood processing utensils, etc., can solve problems such as low work efficiency and easy injury, and achieve the effect of convenient skin scraping and avoiding friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

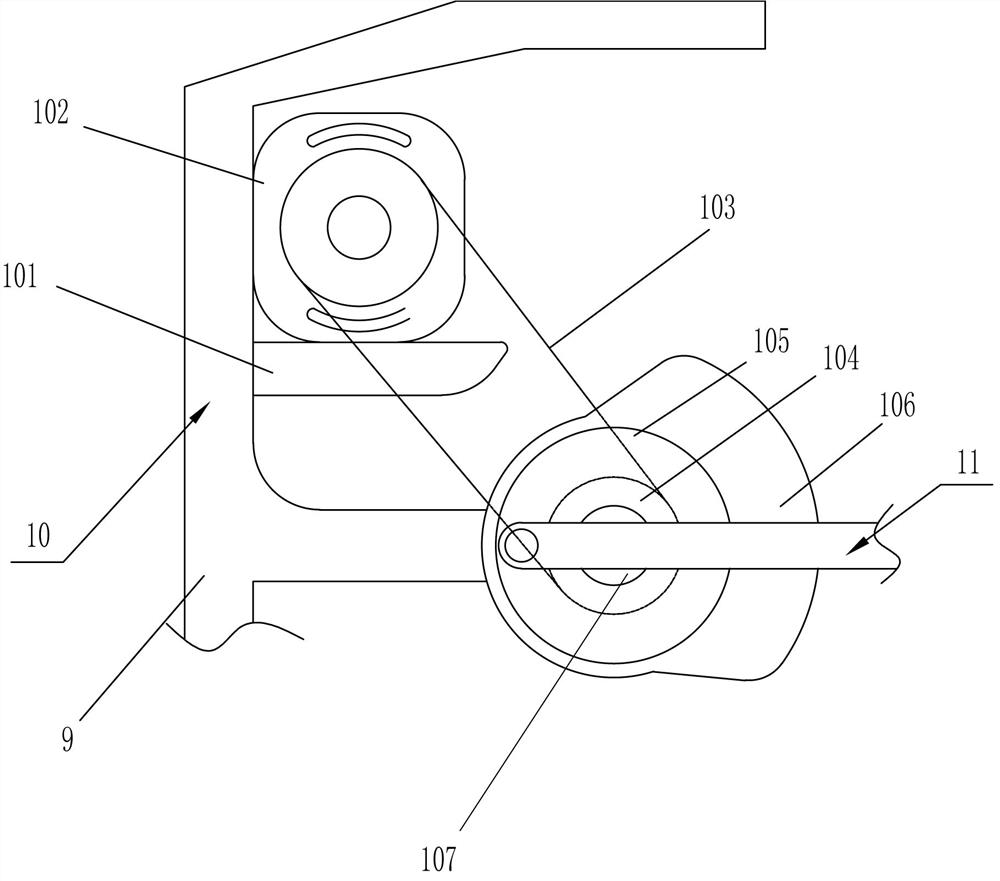

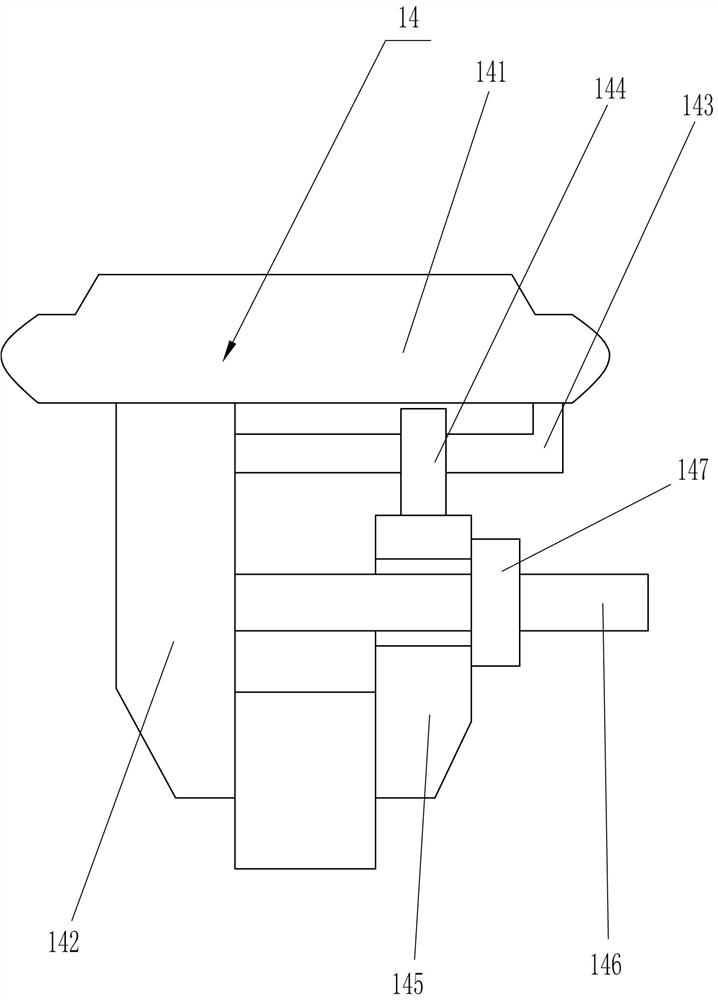

[0024] A kind of birdcage bottom scraping equipment, such as figure 1 As shown, it includes a base 1, a collection frame 2, a first support plate 3, a first support frame 4, a swing device 5, an upper pressing assembly 6, a planer 7, a second support plate 8, a second support frame 9, and a rotating device 10. The reciprocating device 11, the second connecting rod 13 and the clamping device 14, the collection frame 2 is placed on the base 1, the first support plate 3 is provided on the upper left of the base 1, and the swing device is provided on the top right side of the first support plate 3 5. A first support frame 4 is provided on the left side of the top of the first support plate 3, a second support plate 8 is provided on the first support frame 4, a reciprocating device 11 is provided on the right side of the second support plate 8, and a reciprocating device 11 is provided There is a second connecting rod 13, the right side of the second connecting rod 13 is connected ...

Embodiment 2

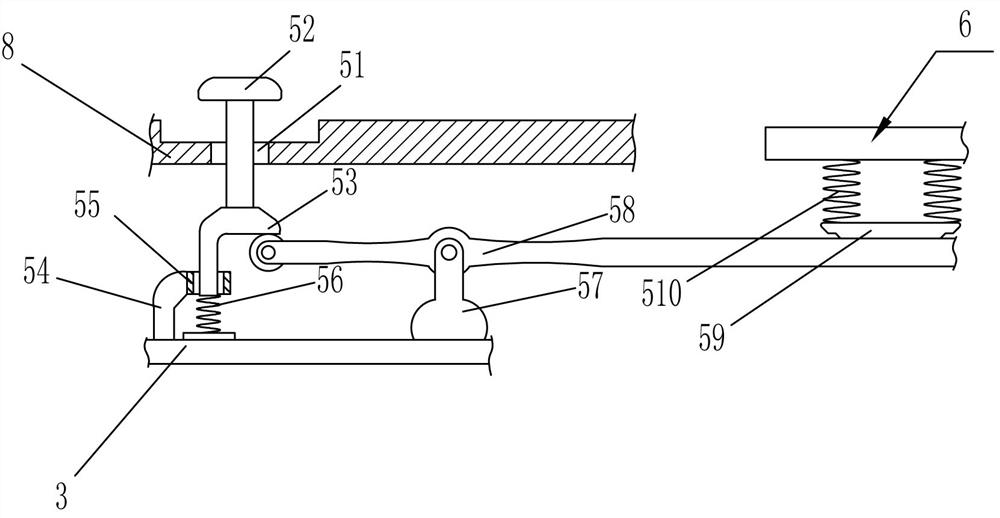

[0027] On the basis of Example 1, such as Figure 1-7As shown, the swing device 5 includes a pressing rod 52, a moving frame 53, a first fixed rod 54, a first sliding sleeve 55, a first spring 56, a support rod 57, a lever 58, a pressing plate 59 and a second spring 510, the first The support plate 3 is provided with a first fixed rod 54, the first fixed rod 54 is connected with a first sliding sleeve 55, the first sliding sleeve 55 is slidably connected with a mobile frame 53, and the bottom of the mobile frame 53 is connected to the first support plate 3. A first spring 56 is connected between the tops, a through hole 51 is opened on the left part of the second support plate 8, and a pressure rod 52 is slidably connected in the through hole 51. The pressure rod 52 cooperates with the rotating device 10, and the bottom of the pressure rod 52 is connected to the On the mobile frame 53, the right side of the first support plate 3 top is provided with a support rod 57, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com