Lead-based perovskite structure high-temperature piezoelectric ceramic and preparation method thereof

A perovskite structure, high-temperature piezoelectric technology, applied in the field of piezoelectric ceramic material preparation, to achieve the effects of increasing strain, improving piezoelectricity, and optimizing ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In some examples, the preparation method of the perovskite structure high temperature piezoelectric ceramic material may include the following steps:

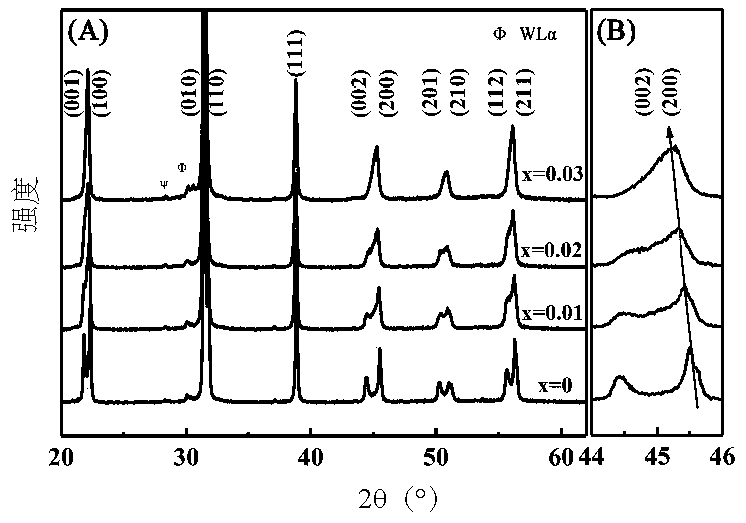

[0031] Step (a), weighing Bi according to the stoichiometric ratio 2 o 3 , PbO, SnO 2 , Sc 2 o 3 , Nb 2 o 5 ,TiO 2 Powder; (1-x)[0.36BiScO 3 -0.64PbTiO 3 ]-xBi(Sn 1 / 3 Nb 2 / 3 )O 3 Ceramic powder.

[0032] The primary wet planetary ball mill is mixed for 2-6 hours according to the mass ratio of raw material: ball milling medium: water = 1: (1.2-1.8): (0.5-0.9). The ball milling medium can be agate balls.

[0033] In addition, the synthesis condition is to synthesize at 600-900° C. for 2-4 hours. Preferably, the temperature is raised to 700-900°C at a heating rate not higher than 2°C / min, kept for 1-3 hours, cooled to room temperature with the furnace, and taken out to obtain a composite.

[0034] The secondary planetary ball mill can be finely ground for 4-8 hours according to the mass ratio of composition: ...

Embodiment 1

[0048] Example 1 is basically the same as Comparative Example 1, the only difference is: x=0.01.

Embodiment 2

[0050] Example 2 is basically the same as Comparative Example 1, the only difference is: x=0.02.

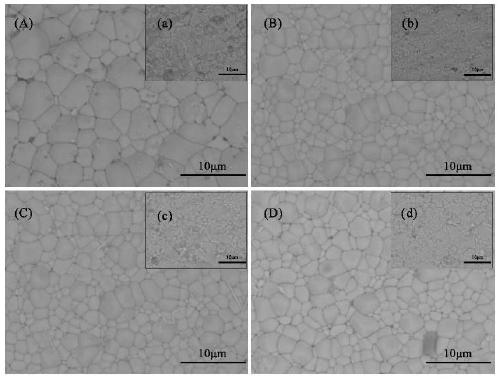

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com