Film coating method and facility

A coating and silicon film technology, which is applied in the field of coating methods and equipment, can solve the problems of slag and defects in the coating process, and achieve the effect of solving defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a coating device, which is suitable for the application scenario of coating the object to be coated into an optical filter, and can solve the problem that the traditional coating process is easy to cause defects due to dross.

[0047] see figure 1 , in this embodiment, the coating equipment includes a target chamber 1 , an ion source chamber 2 and a transplanting mechanism 3 .

[0048] The target chamber 1 is provided with an argon ion plasma beam source and a fixing mechanism for fixing the target material, and is used to bombard the target material with an argon ion plasma beam in an inert environment to form a first silicon film coating on the surface of the object to be coated . The ion source chamber 2 is provided with electrodes for ionizing the first silicon film coating in a hydrogen-rich environment to convert the first silicon film coating into a hydrogenated silicon coating. The transplanting mechanism 3 is provided with a fixed sta...

Embodiment 2

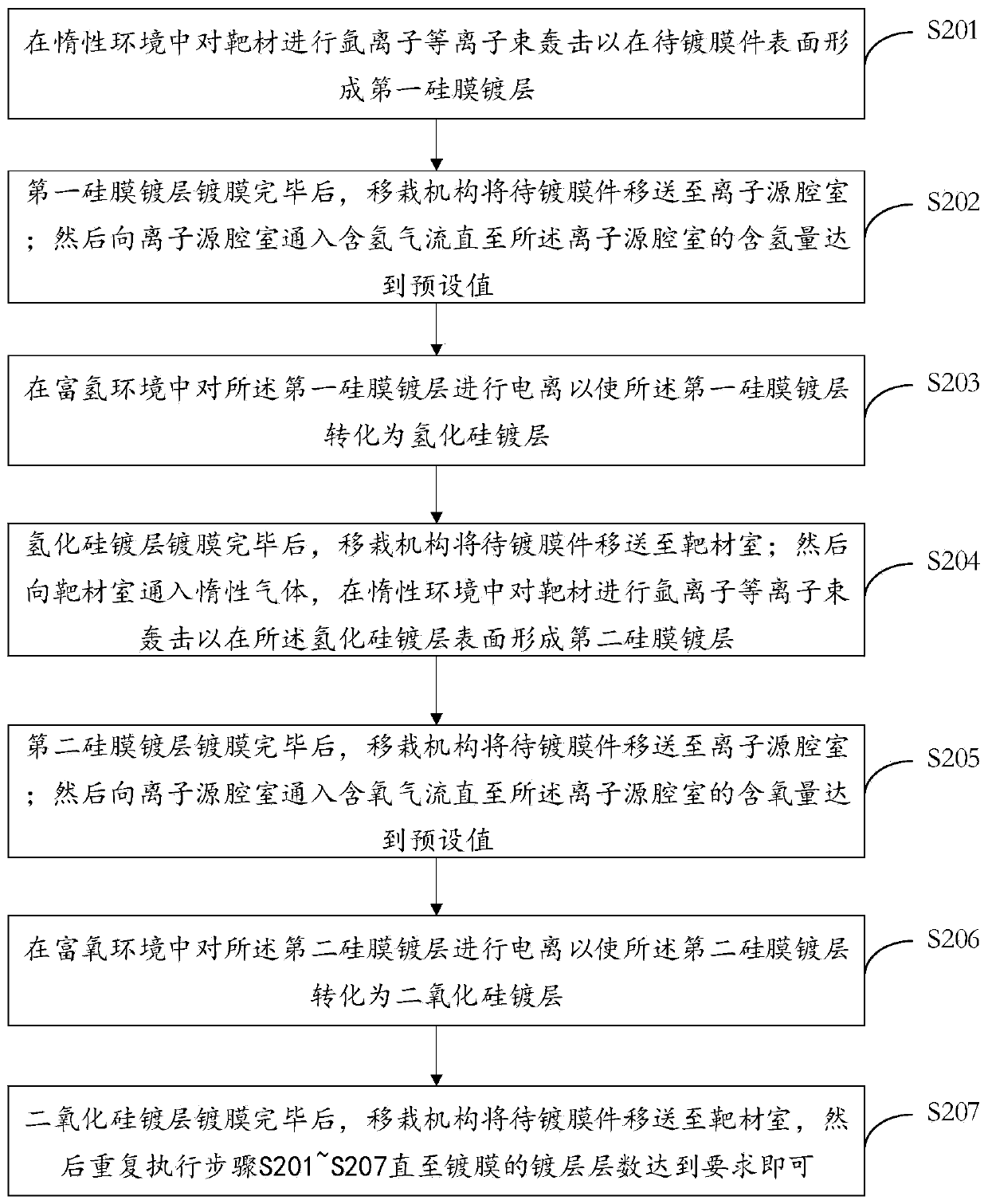

[0053]This embodiment provides a coating method, which is executed by the coating device provided in Embodiment 1, and has the same functions and beneficial effects.

[0054] see figure 2 , the coating method includes:

[0055] S201: Bombarding the target with an argon ion plasma beam in an inert environment to form a first silicon film coating on the surface of the object to be coated.

[0056] Preferably, the inert gas is argon, and the target material is high-purity single crystal silicon or high-purity polycrystalline silicon.

[0057] Specifically, the target is put into the target chamber first, and then an inert gas is introduced into the target chamber. When the target chamber is filled with the inert gas, the air inlet of the target chamber is closed, preheated, and the argon ion plasma beam is bombarded. Coating the first silicon film coating layer.

[0058] S202: After the coating of the first silicon film is finished, the transplanting mechanism moves the piece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap