A kind of preparation method of multi-amino modified nano-zinc oxide loaded polyamide fiber

A nano-zinc oxide, polyamide fiber technology, applied in the direction of single-component polyamide rayon, fiber chemical characteristics, rayon manufacturing, etc., can solve the problem of low surface activity of polyamide fibers, affecting fiber spinning performance, and finishing Poor fastness and other problems, to fill the gap in the preparation technology, the performance does not change color, the performance is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

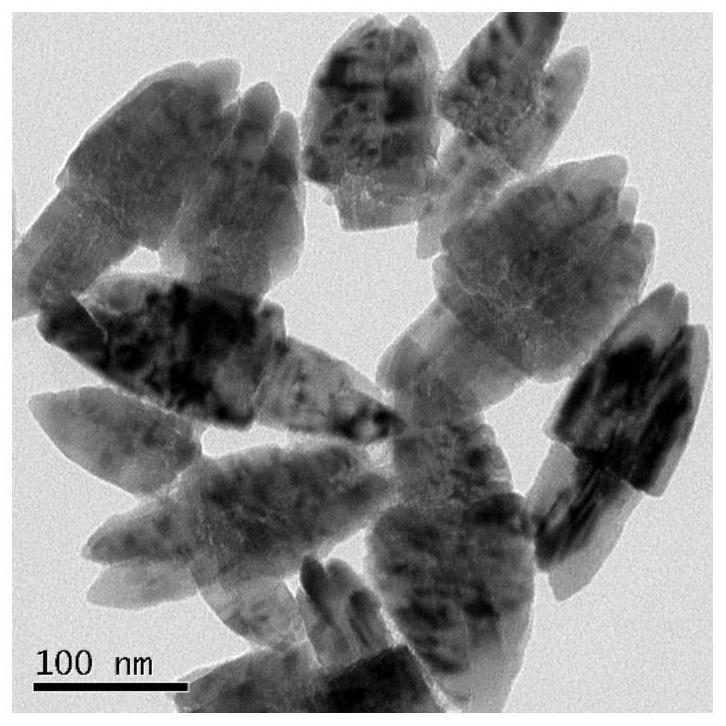

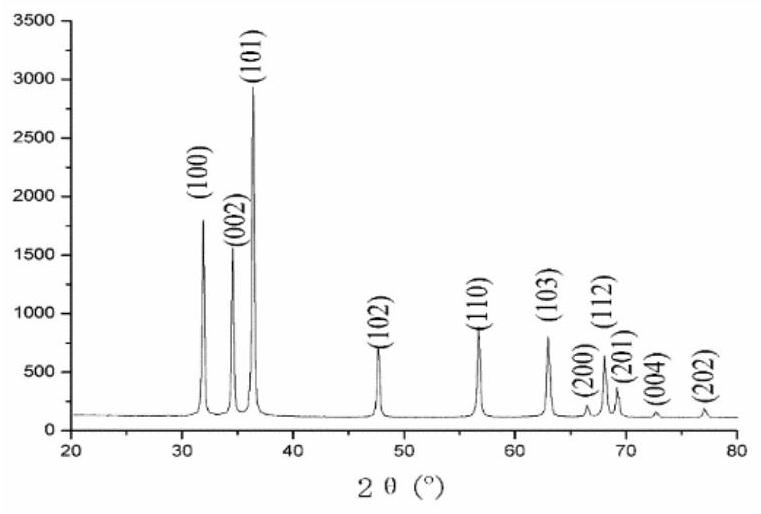

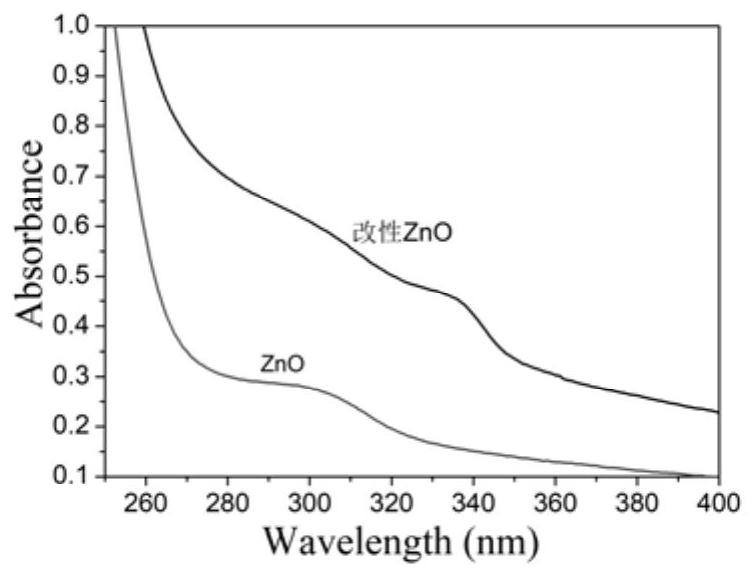

[0025] see Figure 1-3 A polyamino modified nano-zinc oxide-loaded antibacterial and anti-aging polyamide fiber comprises a polyamide matrix in which polyamino-ammonia nano-zinc oxide antibacterial powder is dispersed. The size of the nanometer zinc oxide powder is 20-200nm. The mass ratio of the nano zinc oxide antibacterial powder antibacterial powder to the polyamide matrix is 1:200.

[0026] Its preparation method comprises the following steps:

[0027] A. Prepare 100ml of 0.1M zinc nitrate solution, add hyperbranched polyether to make the concentration 4g / L, add dropwise 0.1mol / L sodium hydroxide solution to produce white turbid precipitate, centrifuge at 400rpm, and bake at 100°C dry reserve;

[0028] B, 0.01mol diethylenetriamine in a 20ml three-necked flask, cooled in an ice-water bath, under N 2 Under protection, dropwise add a mixed solution of 0.004m1 phthalic anhydride and 20m1 methanol with a constant pressure funnel at 2ml / min, and react for 4h to obtain AB...

Embodiment 2

[0034] An amino-modified nanometer-like mutual trust-loaded nano-silver antibacterial and anti-ultraviolet polyamide fiber includes a polyamide matrix (polycaprolactam), and aminated nano-zinc oxide antibacterial powder is dispersed in the polyamide matrix. The size of the nano-zinc oxide antibacterial and anti-ultraviolet powder is 20-400 nm; the mass ratio of the nano-zinc oxide anti-bacterial and anti-ultraviolet powder to the polyamide matrix is 1:100.

[0035] Its preparation method comprises the following steps:

[0036] A, prepare 100ml of 0.2M zinc chloride solution, add hyperbranched polyether to make its concentration 6g / L. Ammonia solution was added dropwise to produce a white turbid precipitate, centrifuged at 400rpm, and dried at 100°C for later use;

[0037] B, 0.01mol triethylenetetramine 20ml three-necked flask, cooled by ice-water bath, under N 2 Under protection, dropwise add a mixed solution of 0.01m1 methyl acrylate and 20m1 methanol with a constant pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com