Popping-pulling type cotton slitting machine

A cotton opener, pop-pull technology, applied in the field of pop-pull cotton opener, can solve the problem of different cotton knocking effects, and achieve the effect of easy beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

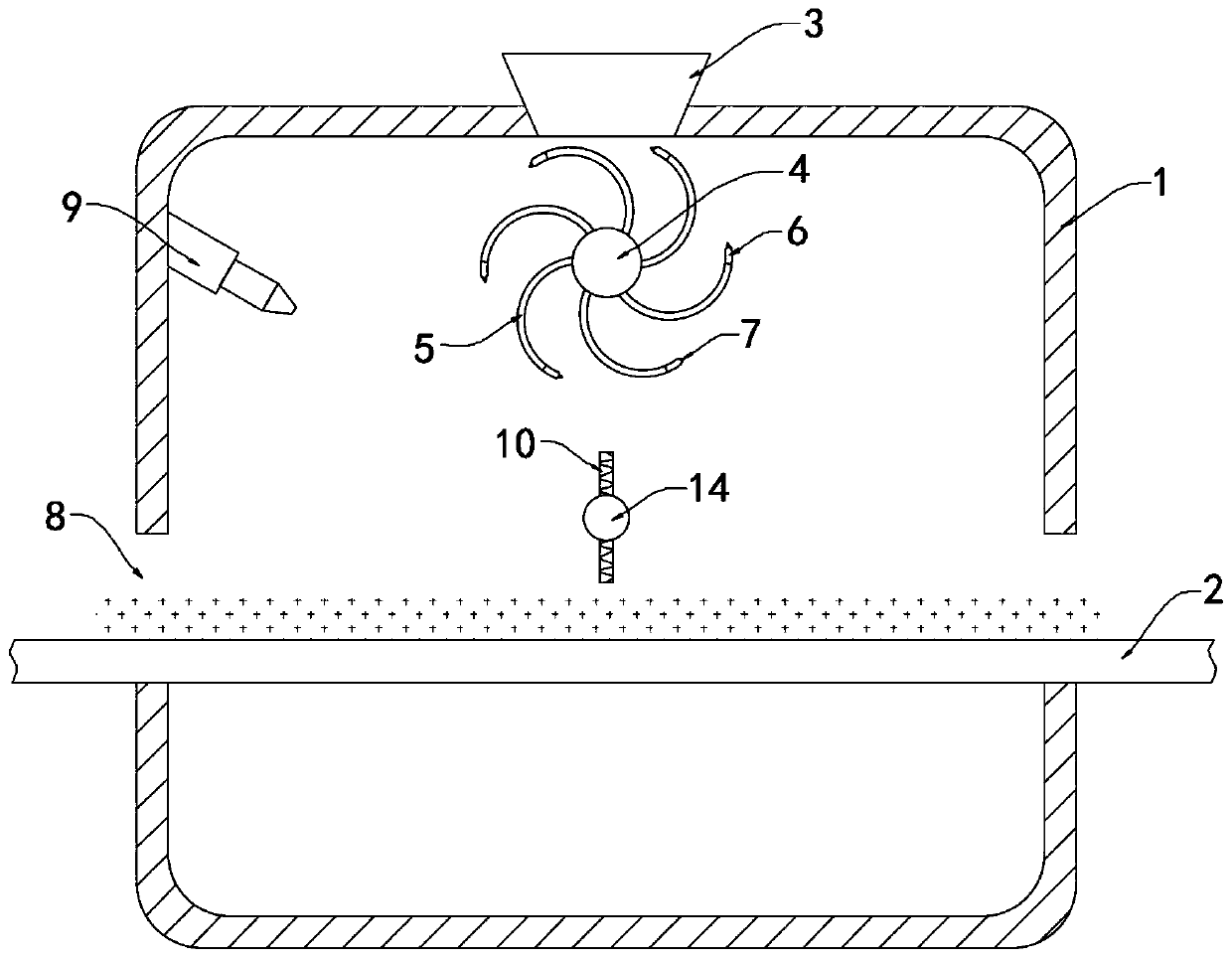

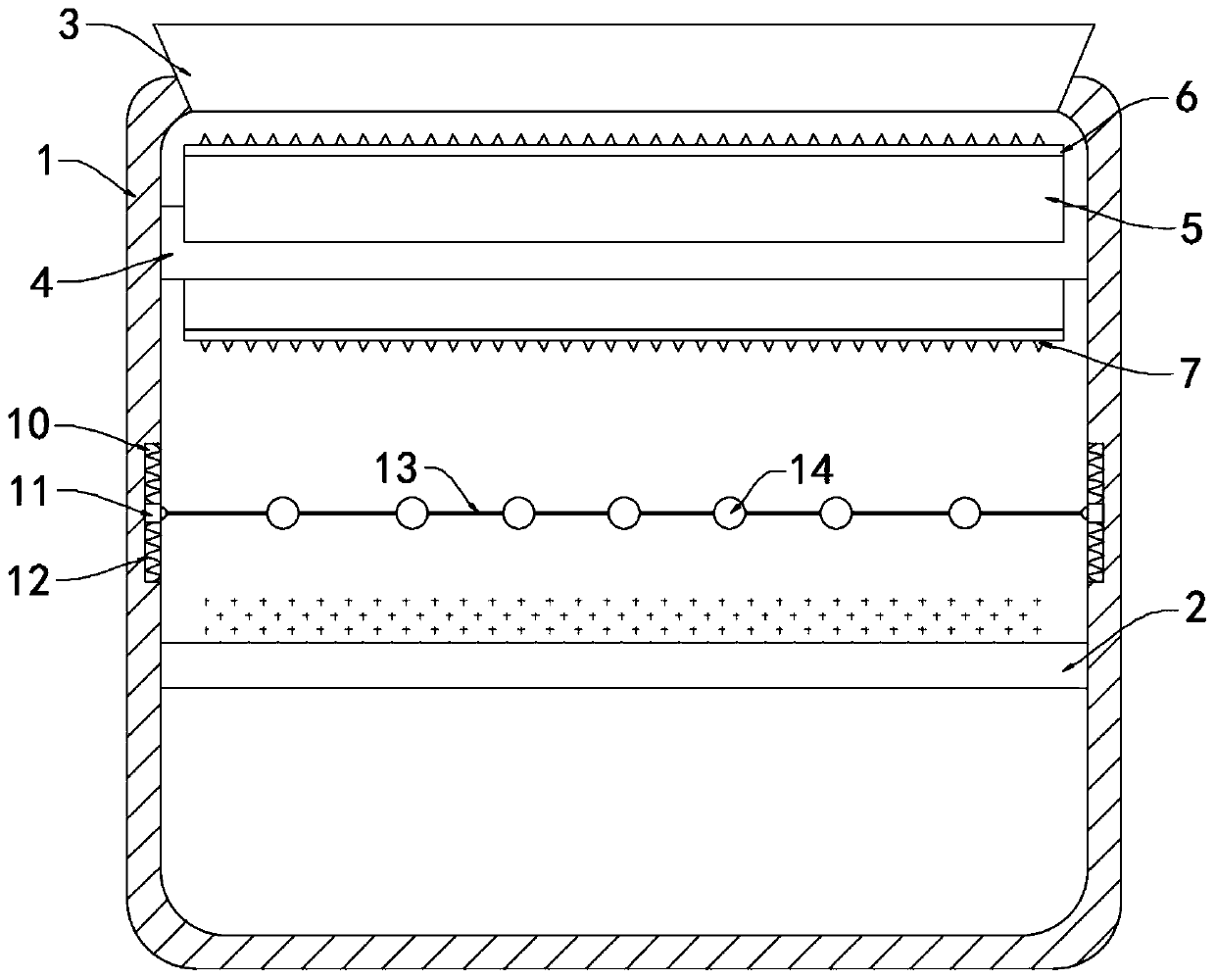

[0022] Such as Figure 1-2 As shown, a spring-pull type cotton opener includes a cotton opening box 1 and a conveyor belt 2, and the conveyor belt 2 is driven by a driving mechanism. This is the prior art and is not the subject of the invention of the device, so it will not be repeated here. The upper end of the cotton opening box 1 is fixedly connected with a strip-shaped cotton inlet hopper 3, and the cotton enters in the cotton opening box 1 through the strip-shaped cotton inlet hopper 3.

[0023] Rotate in the cotton opening box 1 and be connected with the rotating shaft 4 that horizontally arranges, and rotating shaft 4 is arranged on the just below strip-shaped cotton feeding hopper 3, and the side wall of rotating shaft 4 is fixedly connected with a plurality of arc-shaped cotton scraping plates 5 (such as figure 1 As described above), a plurality of arc-shaped cotton scraping plates 5 are arranged rotationally symmetrically with respect to the rotating shaft 4 , and a ...

Embodiment 2

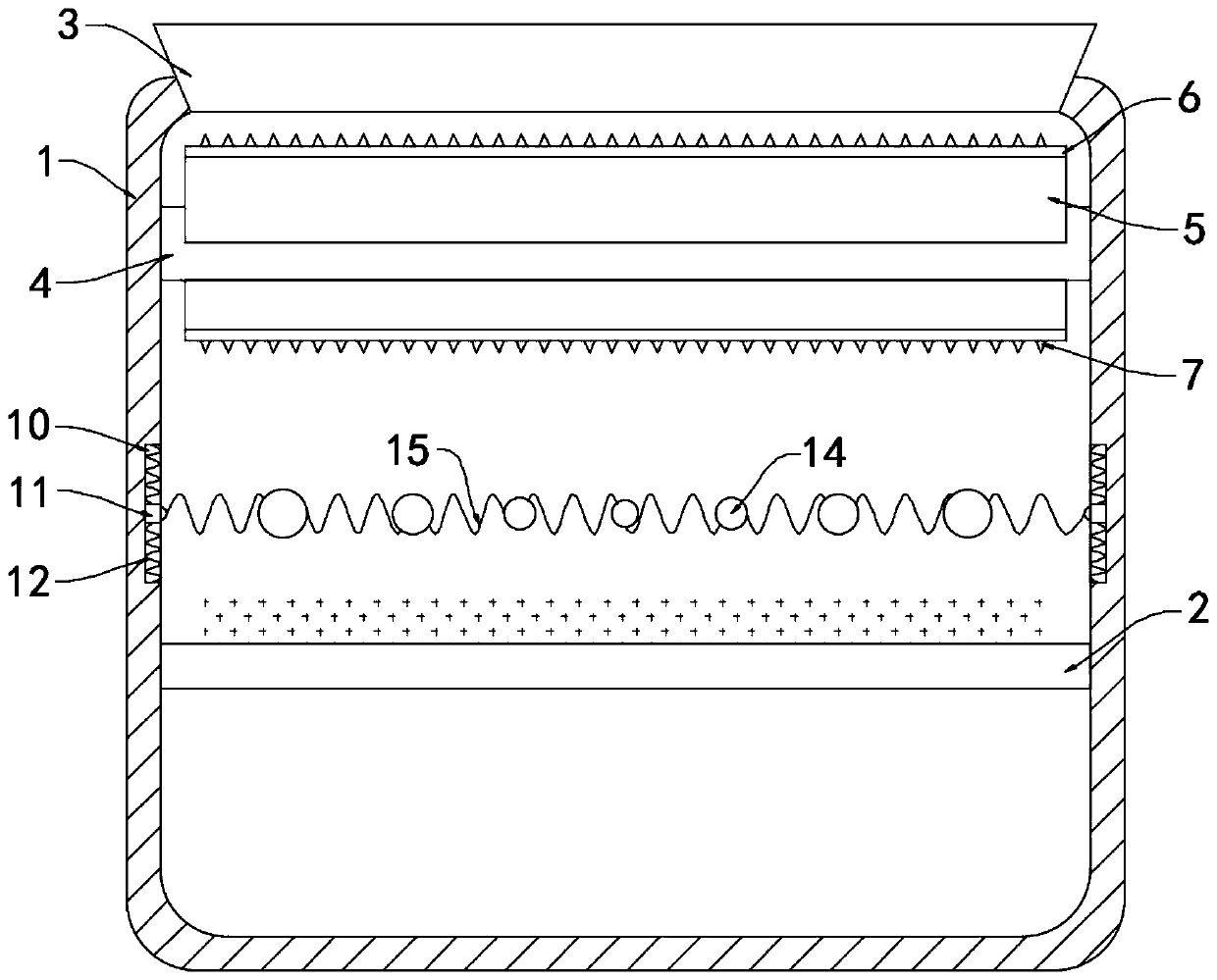

[0034] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: a vibrating spring 15 is fixedly connected between the two sliding blocks 11, and a plurality of counterweights that attract each other with the magnetic strip 6 are fixedly connected on the vibrating spring 15. Ball 14, the mass of a plurality of counterweight balls 14 on the vibrating spring 15 gradually increases from the middle to both sides.

[0035] In this embodiment, in the process of beating up and down of the vibrating springs, the opening and closing between the vibrating springs 15 can play the role of clamping and pulling the cotton, which can make the cotton more fluffy, and when the magnetic strip 6 is far away from the weight ball 14 At the same time, the inertia produced by the counterweight balls 14 of different masses is different, and the counterweight balls 14 on both sides have a larger mass, so the inertia is larger, which can drive the two ends of the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com