Stocking suction cylinder motion mechanism of integrated machine

A technology of motion mechanism and sock suction cylinder, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of reduced service life, increased exercise time, and increased failure rate, so as to shorten the moving distance and time, increase Circular working rhythm, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

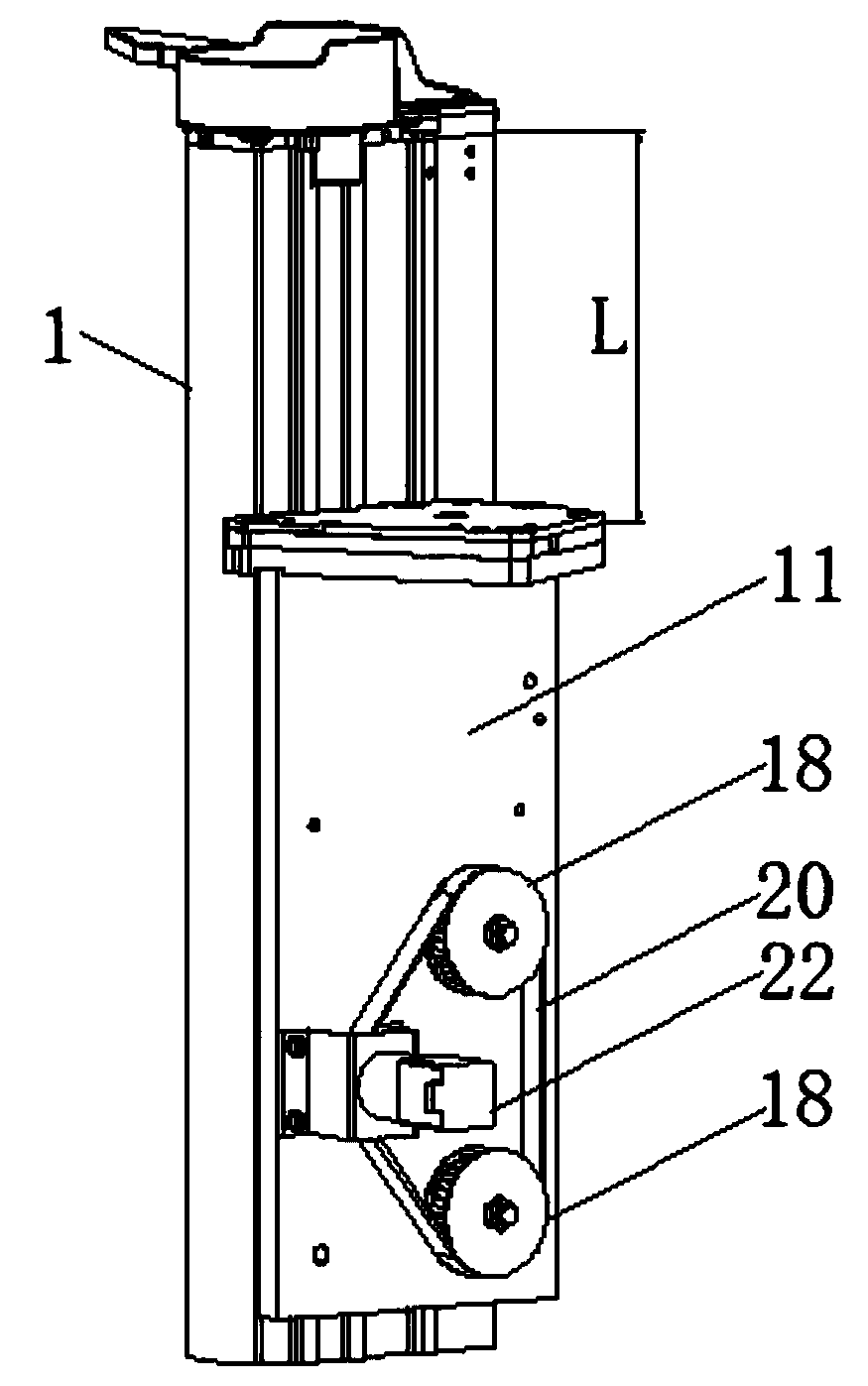

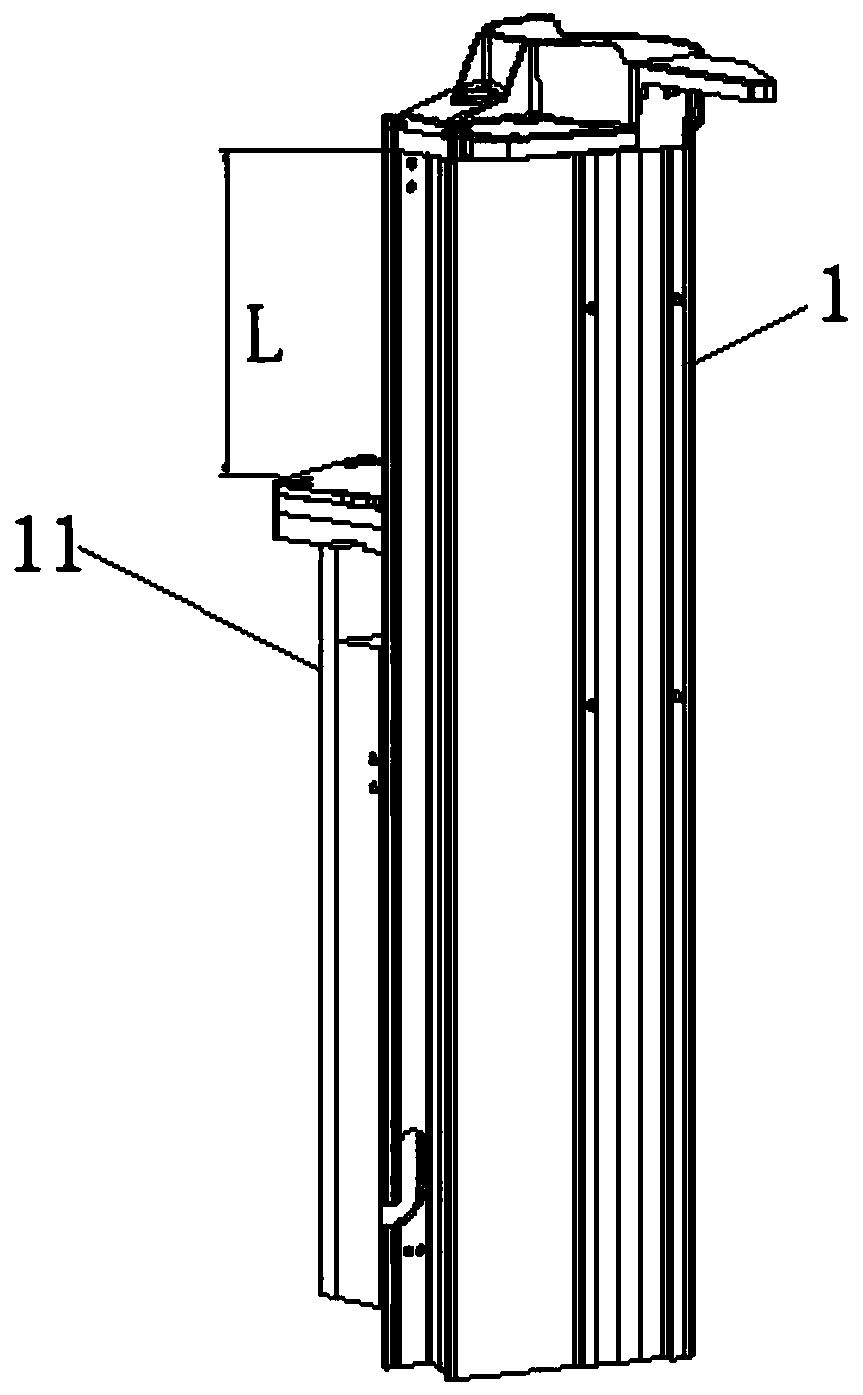

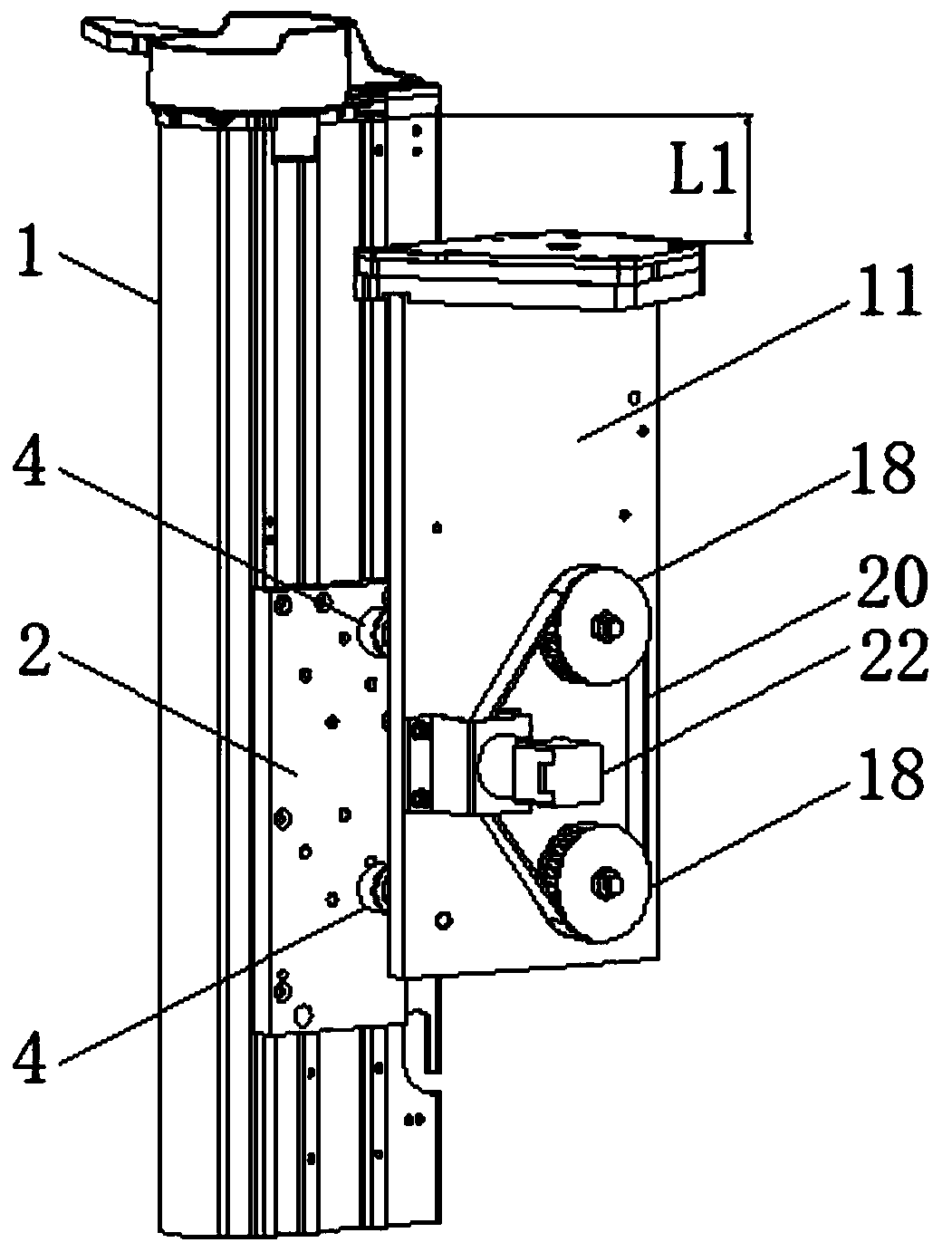

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0027] like figure 1 , figure 2 , Figure 5 As shown in the figure, the kinematic mechanism of the all-in-one sock suction tube, the fixed plate 2 is installed on the side of the rigid column 1, the fixed plate 2 is fixedly installed with the body of the hosiery machine, and two axial screws 3 are installed on the fixed plate 2,

[0028] Both ends of the rocker arm 4 are provided with through holes, and deep groove ball bearings-5 are arranged in the through holes at one end of the rocker arm 4. The deep groove ball bearings-5 are connected with the short shaft at the other end of the shaft position screw 3 and fixed axially. To avoid disengagement, the rocker arm 4 connected with the shaft screw 3 can be tilted and flipped;

[0029] The two ends of the limit block 10 are fixedly installed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com