H type steel beam and H type steel column major axis assembled joint and construction method

A technology of H-beam and shaft assembly, applied in the direction of columns, piers, pillars, etc., can solve the problems of stress concentration, inconvenient on-site construction and installation of workers, etc., to achieve the effect of high node stiffness, increase connection stability, and improve convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

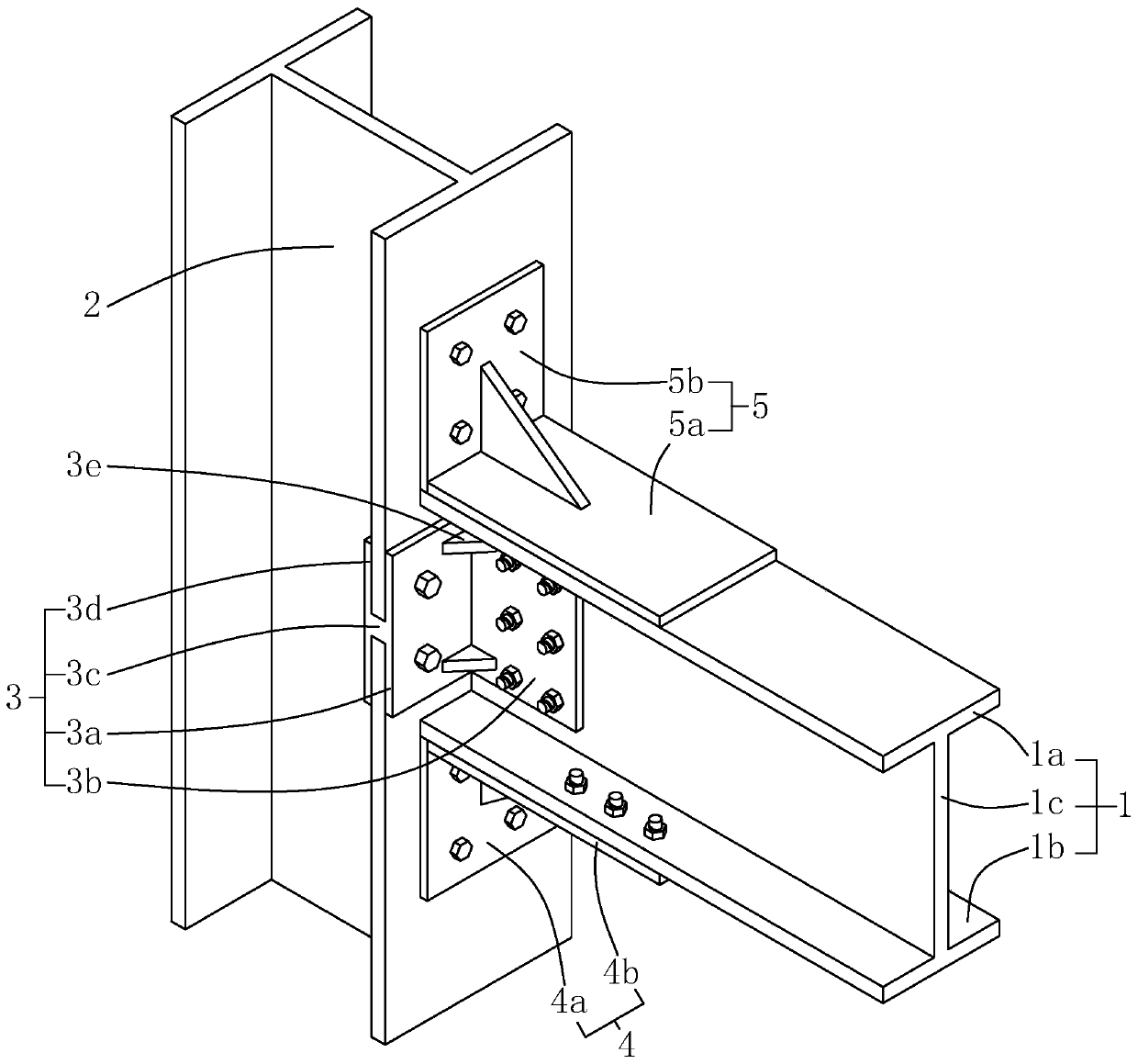

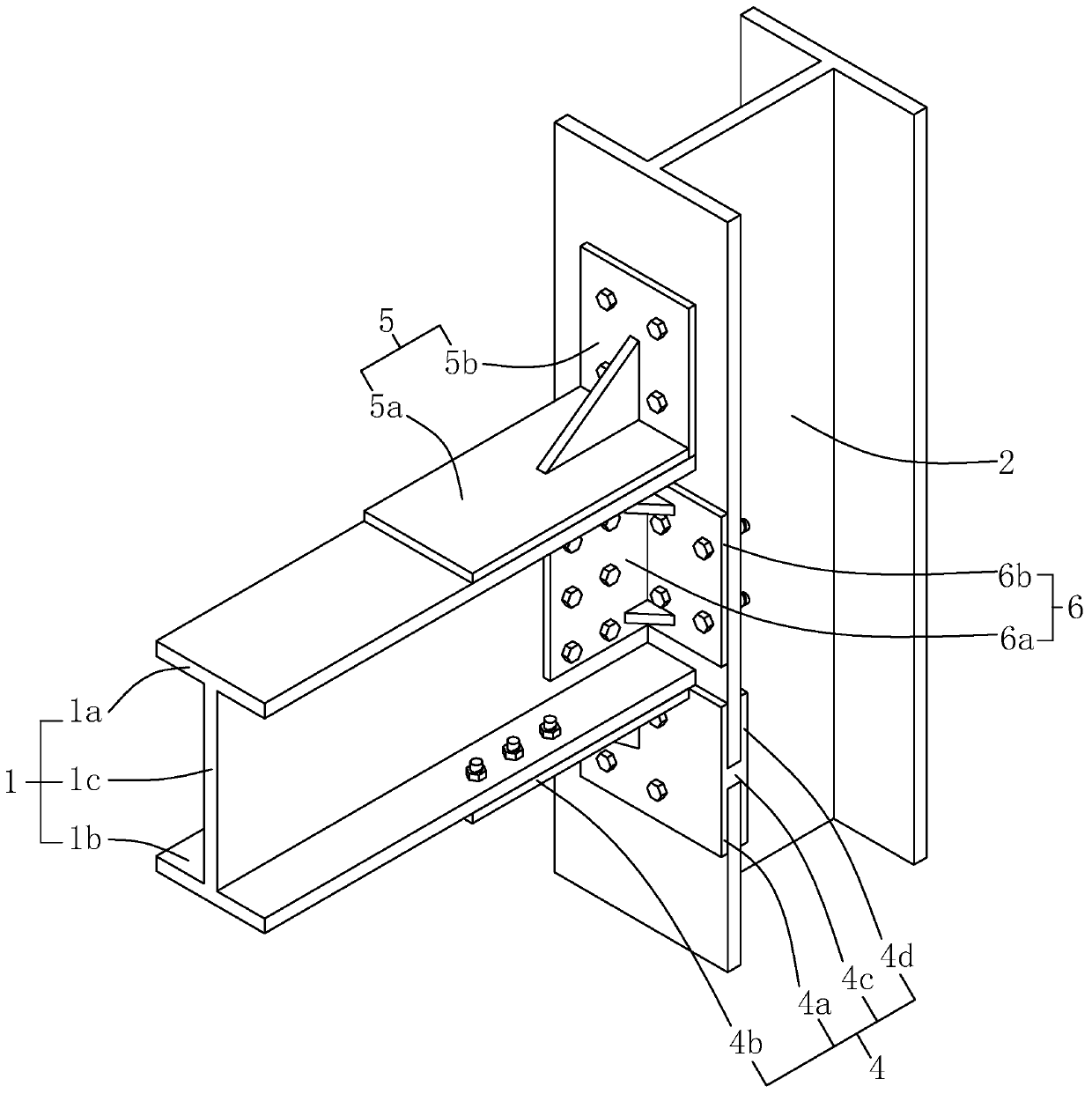

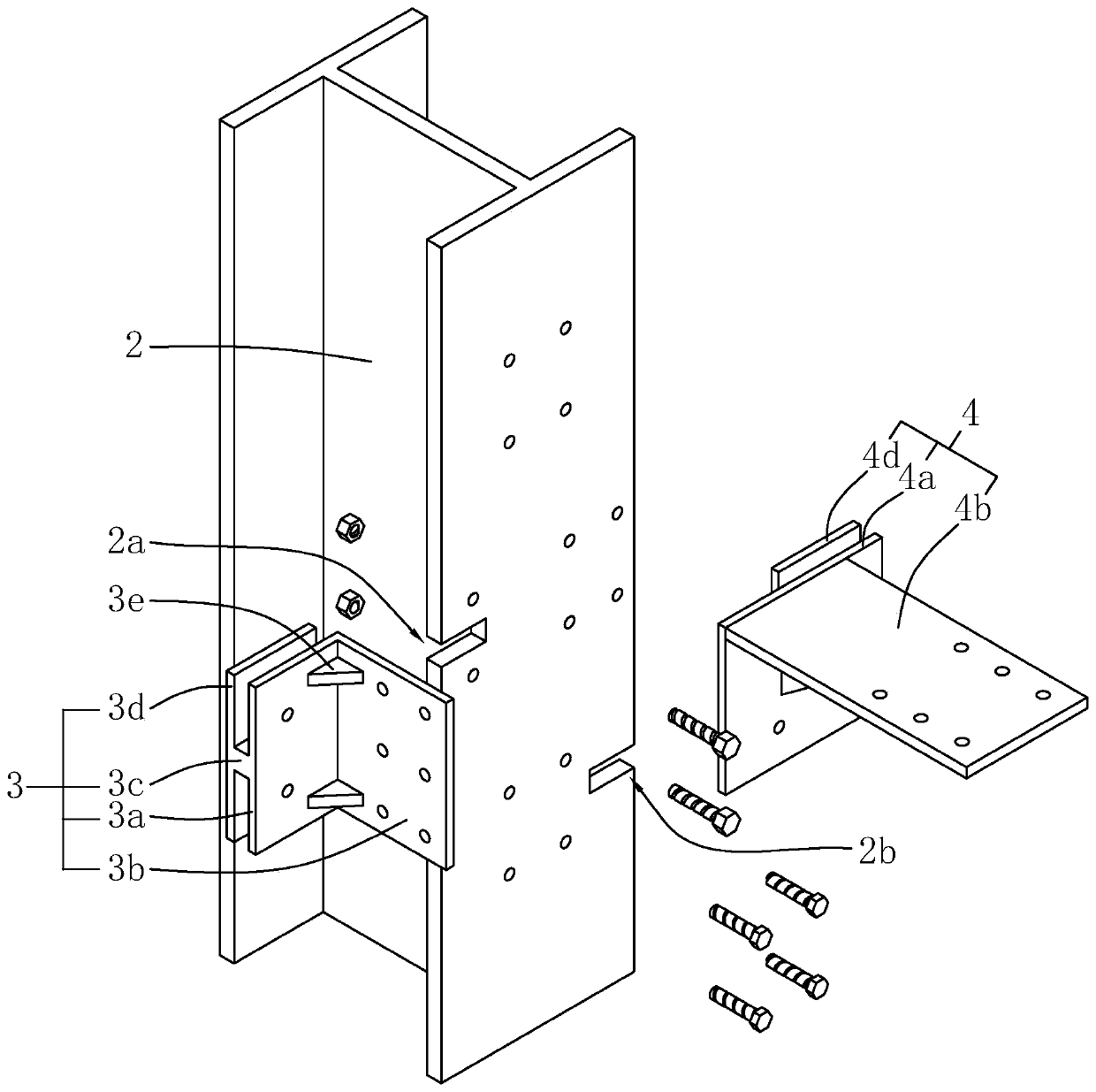

[0039] refer to figure 1 with figure 2 , which is an H-shaped steel beam and H-shaped steel column strong shaft assembled node disclosed in the present invention, including H-shaped steel beam 1, H-shaped steel column 2, first connecting piece 3, second connecting piece 4, and third connecting piece 5 and the fourth connector 6; wherein, the H-shaped steel beam 1 includes a horizontal upper flange 1a, a lower flange 1b and a vertical web 1c; the H-shaped steel column 2 is vertically arranged, and the H-shaped steel column A wing plate of 2 is used to connect with the H-shaped steel beam 1.

[0040] refer to figure 1 with image 3 , the first connecting piece 3 is installed on the wing plate of the H-shaped steel column 2, the first connecting piece 3 includes a first L-shaped plate, a first plug-in block 3c and a first limiting plate 3d, specifically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com