Shape memory alloy cotter

A memory alloy and cotter pin technology, which is applied to threaded fasteners, connecting components, screws, etc., can solve the problems of loss of anti-retraction, anti-loosening functions, difficult removal, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

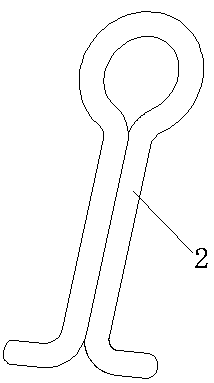

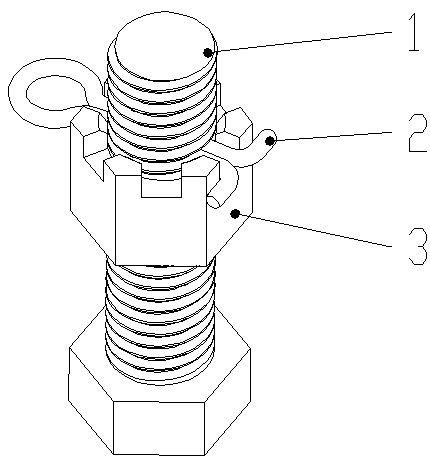

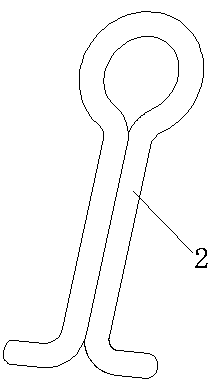

[0011] Such as figure 1 As shown, the shape memory alloy cotter pin includes a NiTi shape memory alloy cotter pin body 2, the NiTi shape memory alloy cotter pin body 2 is a U-shaped card structure with a ring structure at one end, and the NiTi shape memory alloy cotter pin body 2 has two tails. a transverse tail.

[0012] Such as figure 2 As shown, when the present invention is in use, the operator puts the present invention in an environment below 0°C to fully cool it, and deforms its tail, and straightens the two transverse tail fins for easy installation. After the bolt 1 and nut 3 are installed in place, Insert the deformed cotter pin into the bolt hole, and heat it with a heat source above 40°C (a lighter, hair dryer or heat gun can be used for heating). The cotter pin undergoes reverse transformation of martensite when heated, and the macroscopic performance shows that it returns to the shape before deformation, so as to achieve anti-corrosion. The function of anti-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com