Semi-automatic ball filling device for retainer-free full ball bearing and ball filling method thereof

A technology of full ball bearings and cages, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low efficiency of manual ball filling and high work intensity, so as to reduce scratches, reduce labor intensity, and ensure finished products The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

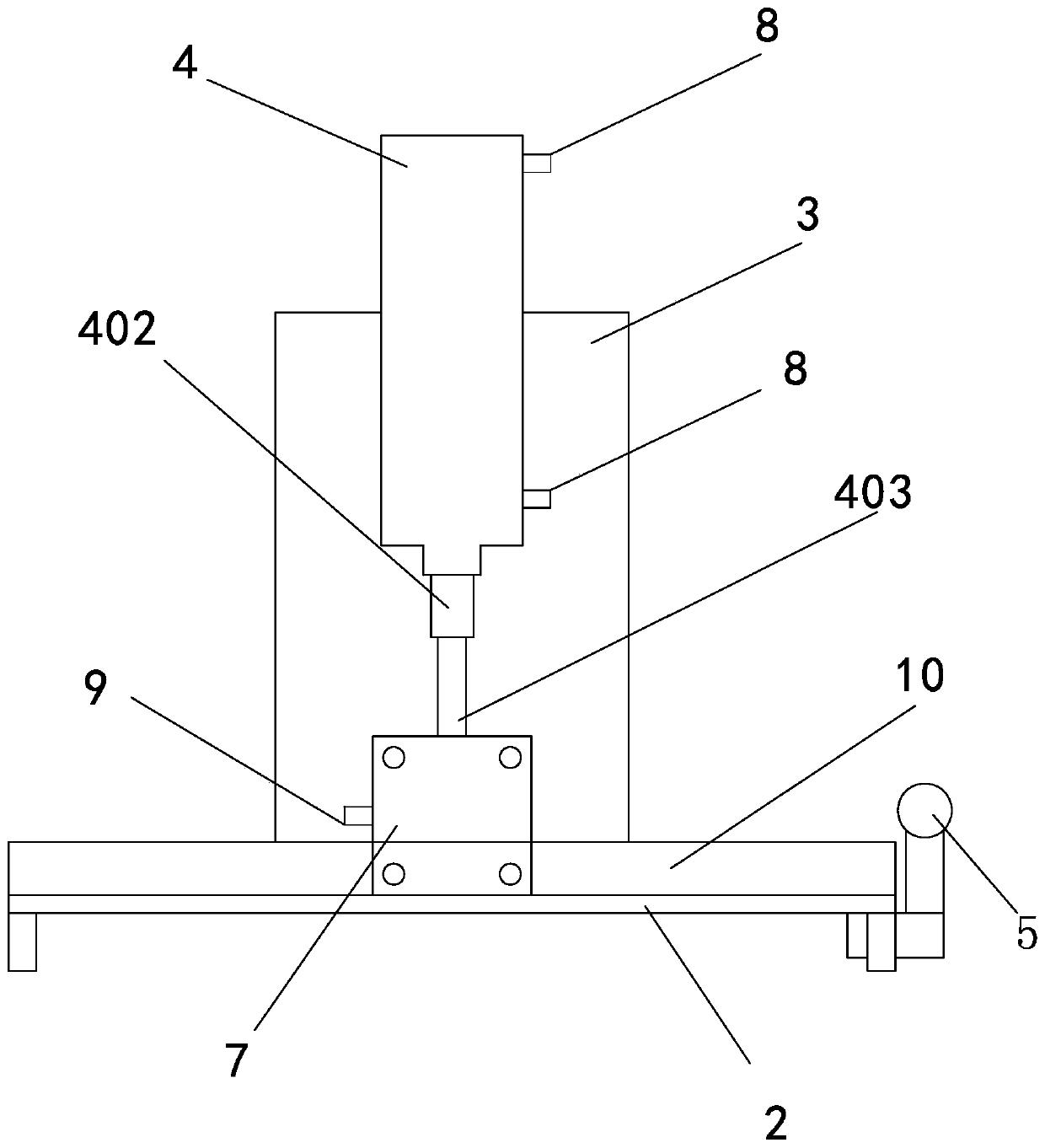

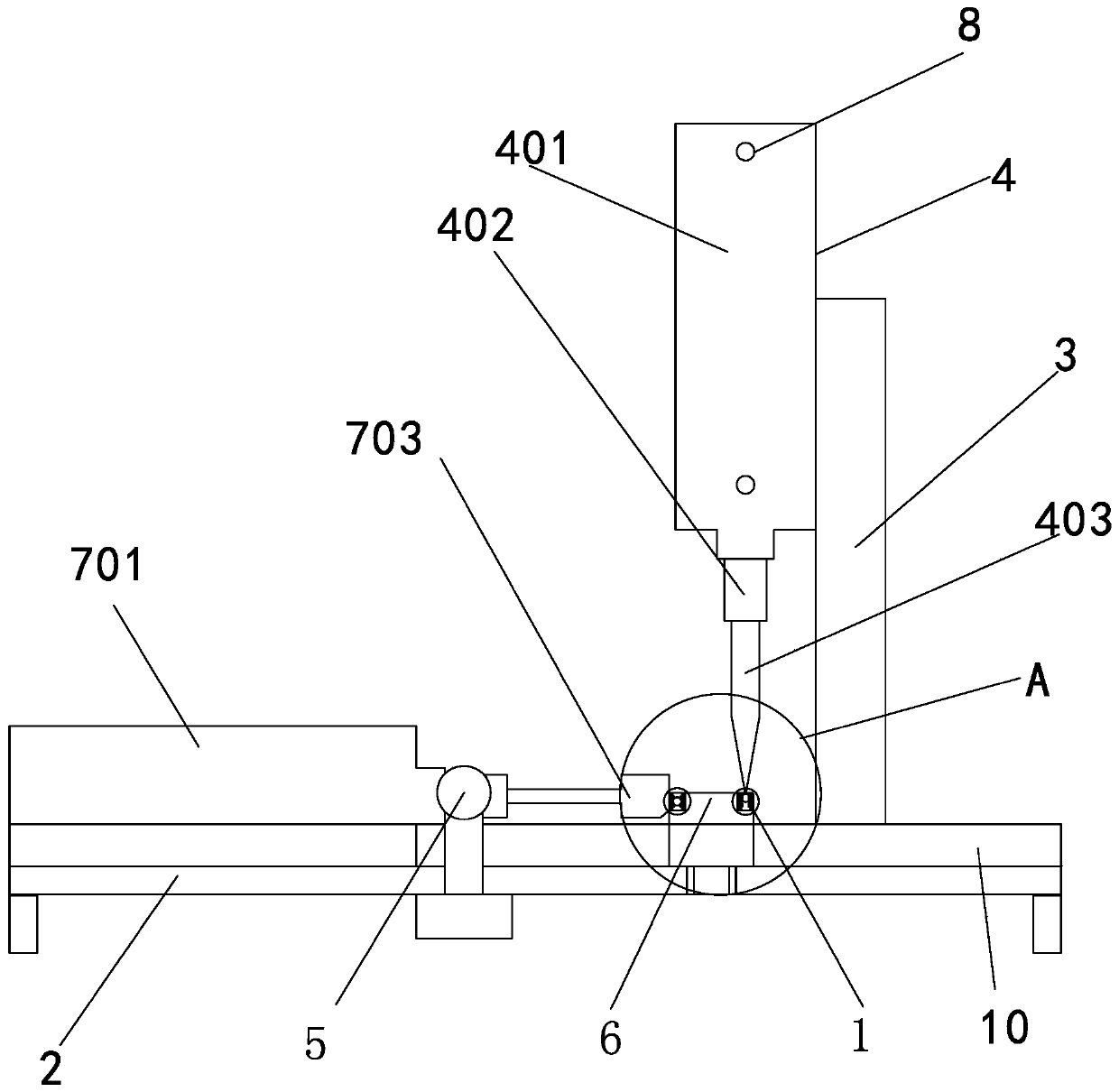

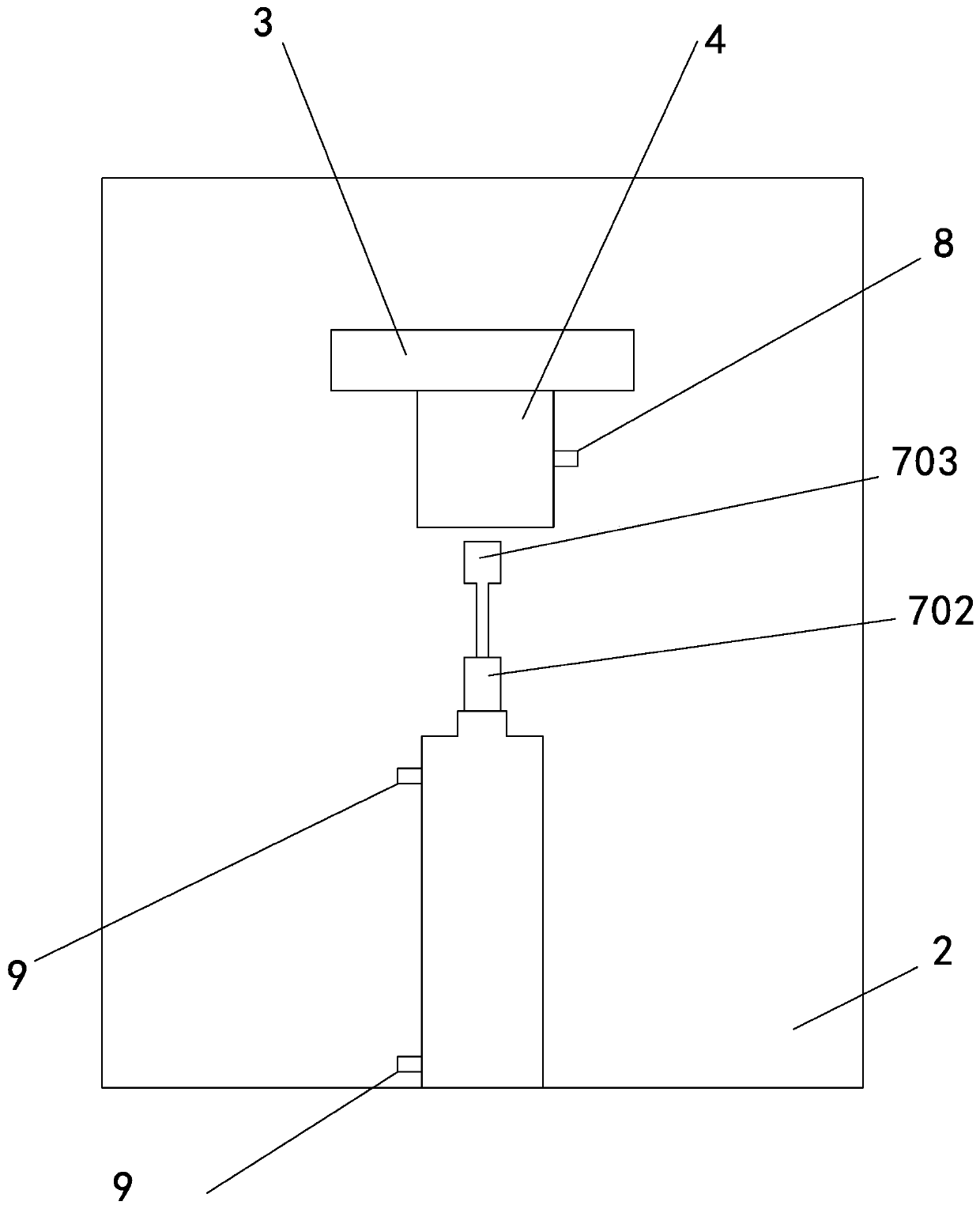

[0035] Such as Figure 1 to Figure 7 As shown, the semi-automatic ball filling device for a cageless full ball bearing includes a cageless full ball bearing 1; the cageless full ball bearing 1 includes an outer ring 101, an inner ring 102 and several steel balls 103, the inner ring 102, An annular cavity 104 filled with steel balls 103 is formed between the outer rings 101, the middle section of the annular cavity 104 is the working position of the steel ball 103 raceway, and the upper section of the annular cavity 104 is the clamping position of the steel ball 103;

[0036] The device also includes a base plate 2, a fixed panel 3, a cylinder system A 4, a manual switch 5, a bearing socket 6, a cylinder system B7 and a foot switch (not shown in the figure), and the manual switch 5 controls the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com