Large-scale point cloud data-based large-scale high-speed rotary equipment error hybrid evaluation method

A technology for point cloud data and error evaluation, applied in the field of error hybrid evaluation, can solve the problems of inaccurate measurement results and unusable results, and achieve the effects of simple calculation, improved assembly accuracy, and reduced complexity and calculation amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

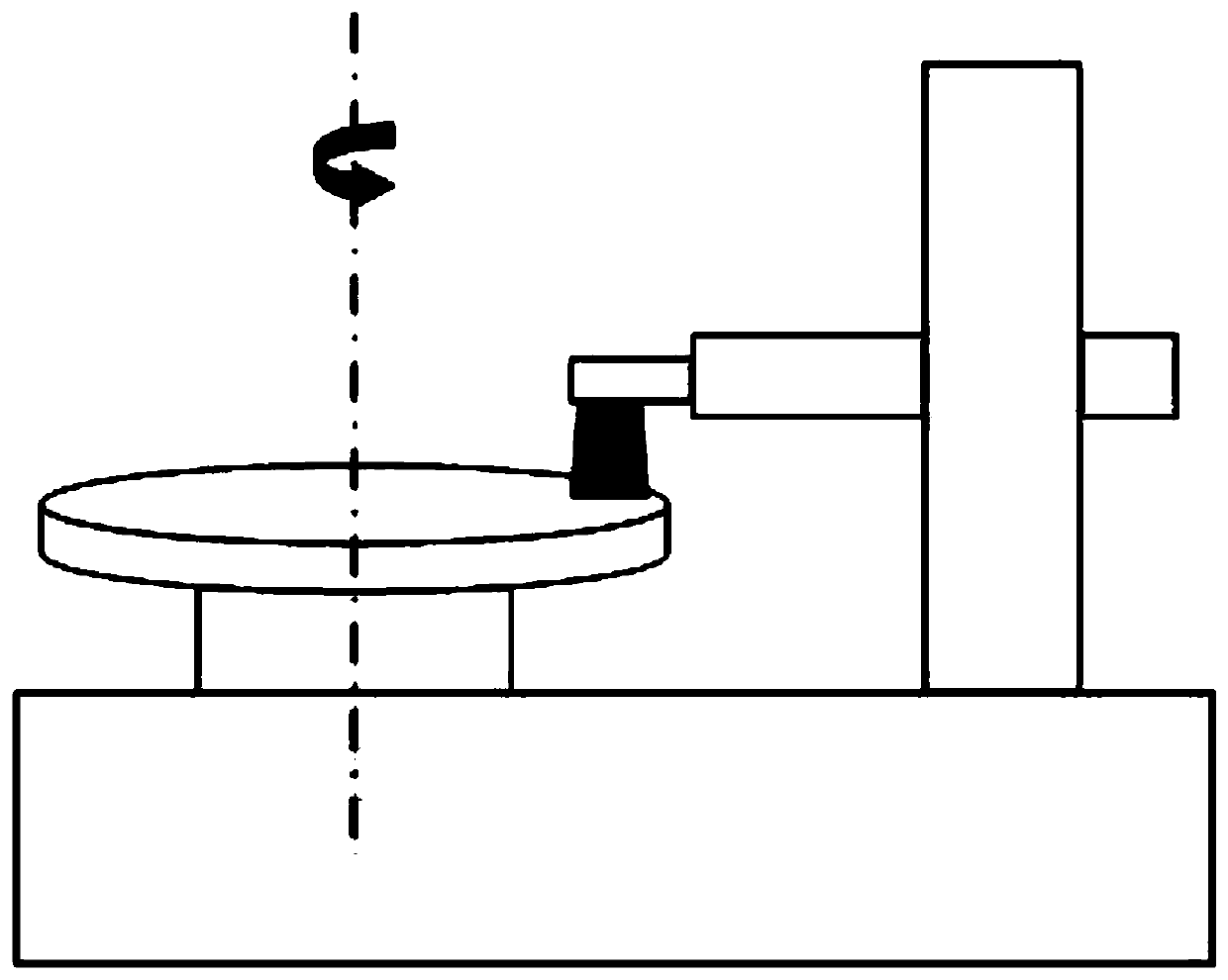

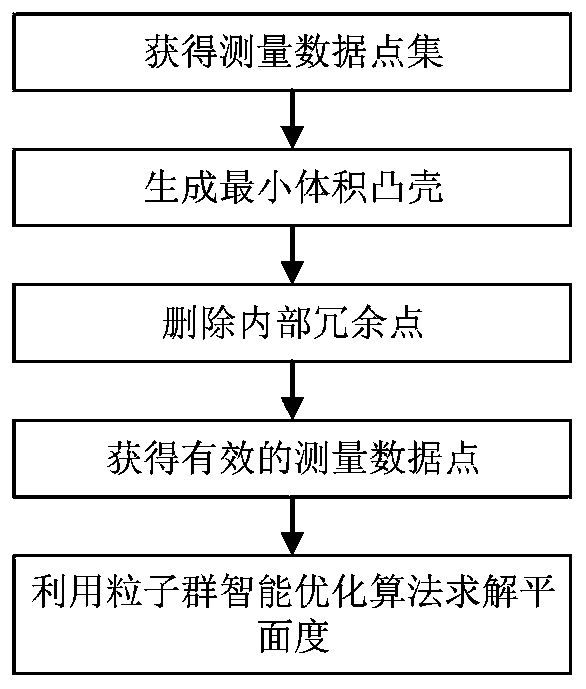

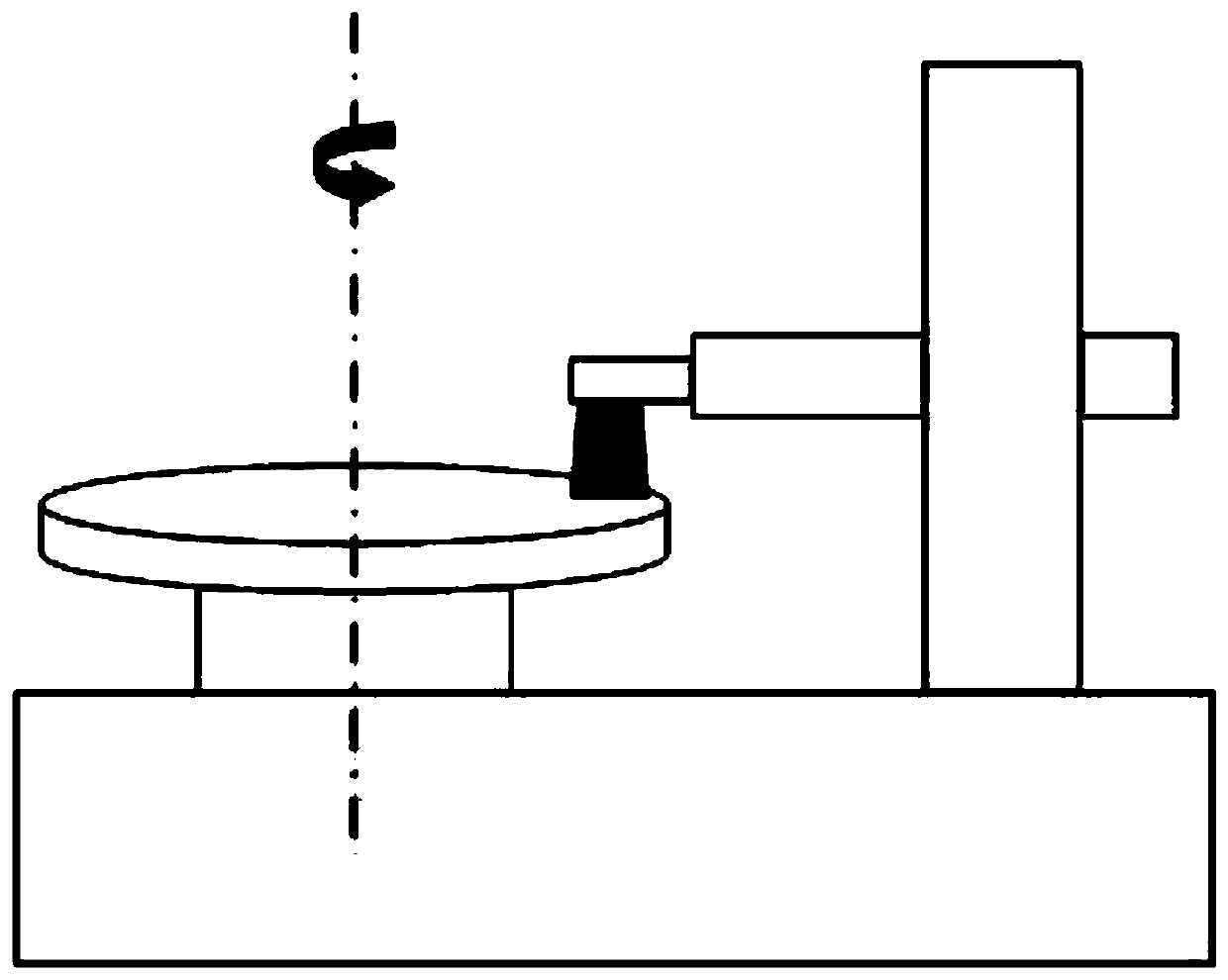

[0034] according to figure 1 and figure 2 As shown, the present invention provides a large-scale high-speed rotary equipment error hybrid evaluation method based on large-scale point cloud data, including the following steps:

[0035] Step 1: According to the flatness error evaluation method of the minimum area criterion, determine that the upper and lower planes of all measured point sets are the containment planes;

[0036] The step 1 is specifically:

[0037] According to the flatness error evaluation method of the minimum area criterion, the upper and lower planes of all measured point sets are determined to be the containment plane, and the reference normal vector equation of the containment plane is expressed by the following formula:

[0038] Ax+By+Cz+D=0 (1)

[0039] Among them, A, B, C are the normal vectors of the reference plane, and D is the offset distance along the normal direction of the containment plane.

[0040] Step 2: update the speed and position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com