Semiconductor substrate thinning method

A semiconductor and substrate technology, applied in the field of semiconductor substrate thinning, can solve problems such as cumbersome operation and poor flatness of semiconductor substrates, and achieve the effects of simplifying the thinning process, reducing the cost of thinning, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

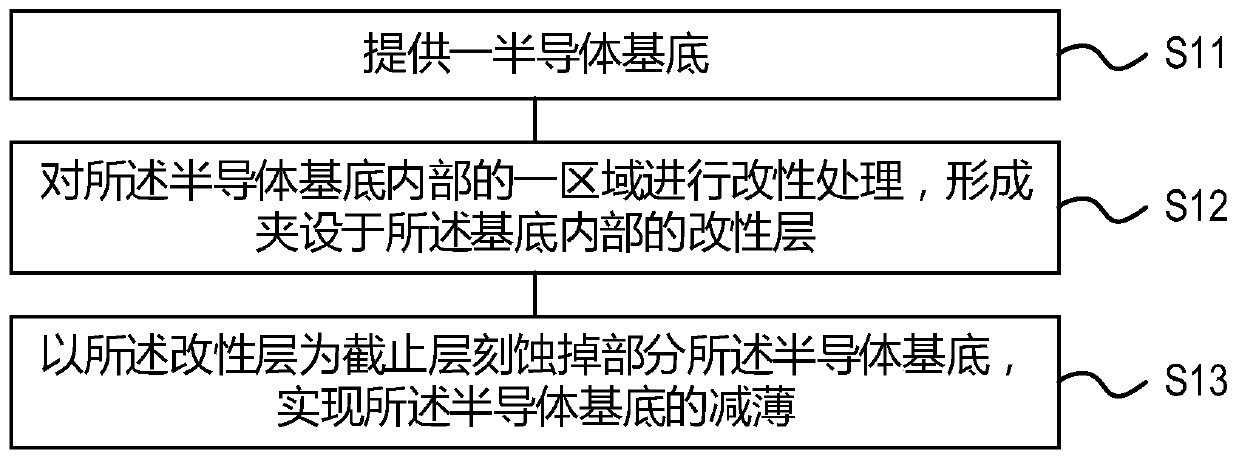

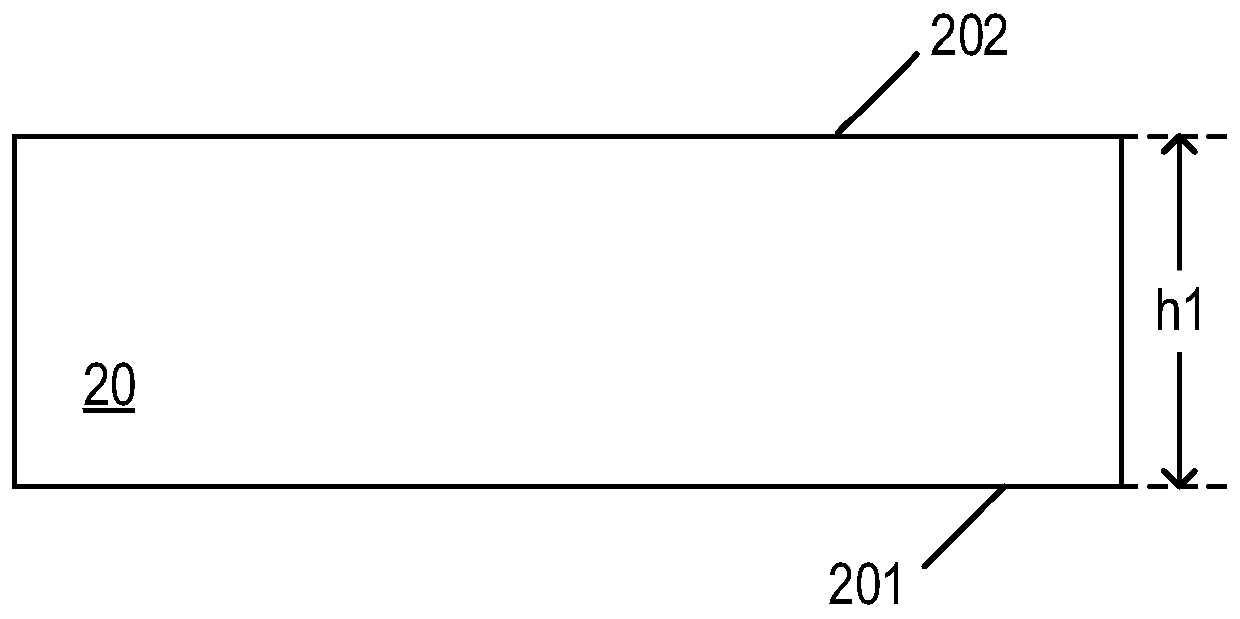

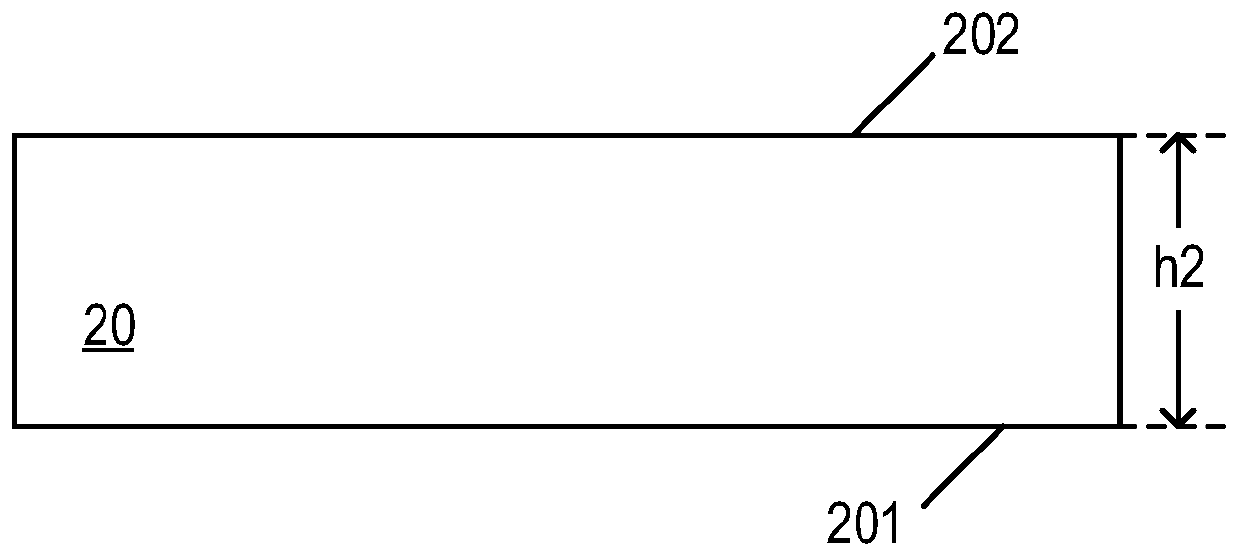

[0029] The specific implementation of the semiconductor substrate thinning method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Currently, in the process of thinning the semiconductor substrate of a semiconductor device, it is mainly accomplished through multi-step chemical mechanical polishing steps, or a combination of multi-step chemical mechanical polishing and wet etching processes. However, the chemical mechanical polishing process itself is complex, time-consuming, and expensive; in addition, the chemical mechanical polishing process still has great challenges in controlling the flatness of the polished semiconductor substrate surface.

[0031] Therefore, in order to optimize the thinning process of the semiconductor substrate, reduce the semiconductor manufacturing cost and improve the semiconductor production efficiency, this specific embodiment provides a method for thinning the semiconducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com