Belly-breaking back-cutting fish-killing all-in-one machine

An all-in-one machine and rack technology, applied in fish processing, fish cleaning/descaler, slaughtering, etc., can solve the problems of complex structure, prone to frostbite, low work efficiency, etc., and achieve small machine size, convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

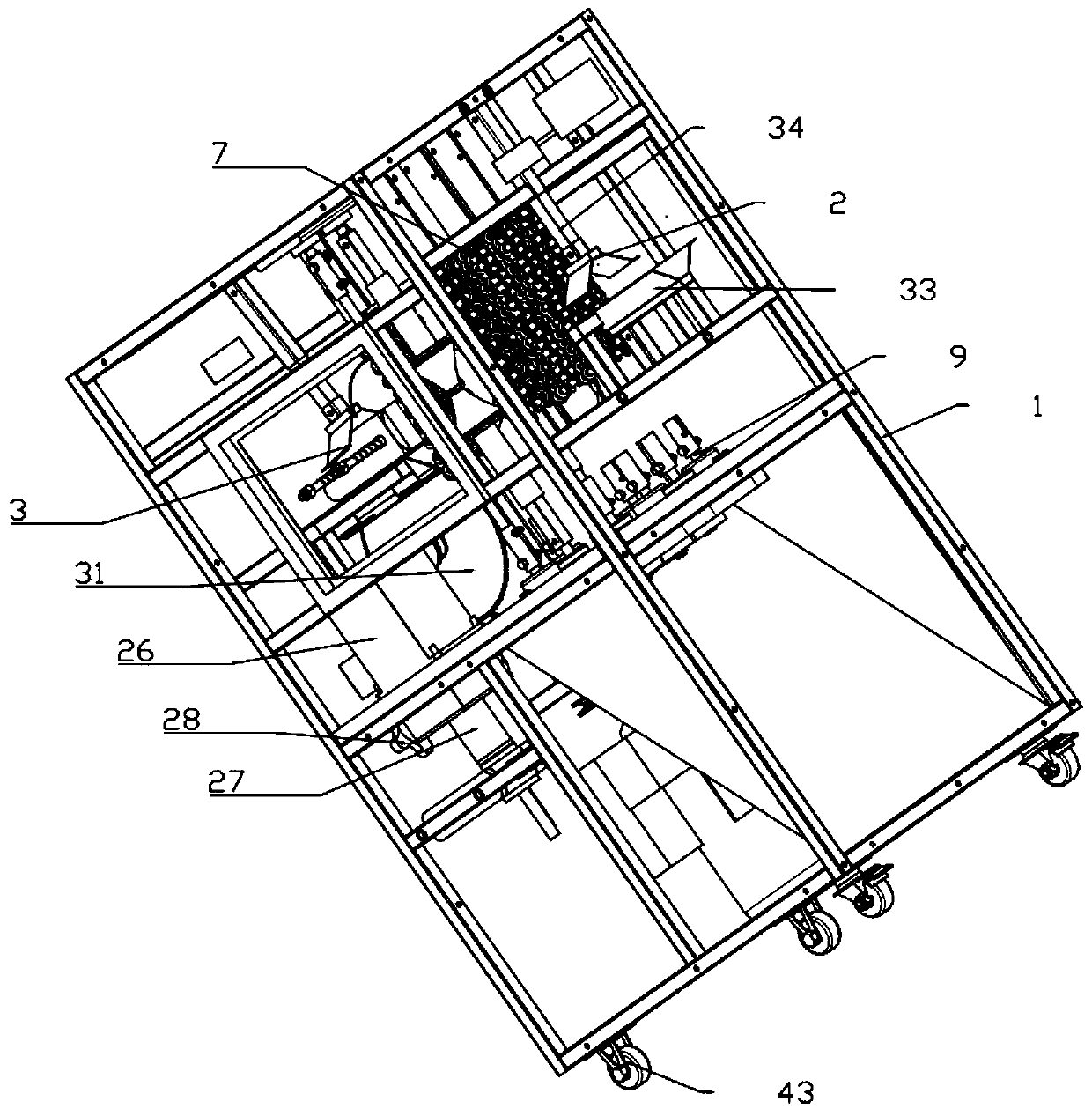

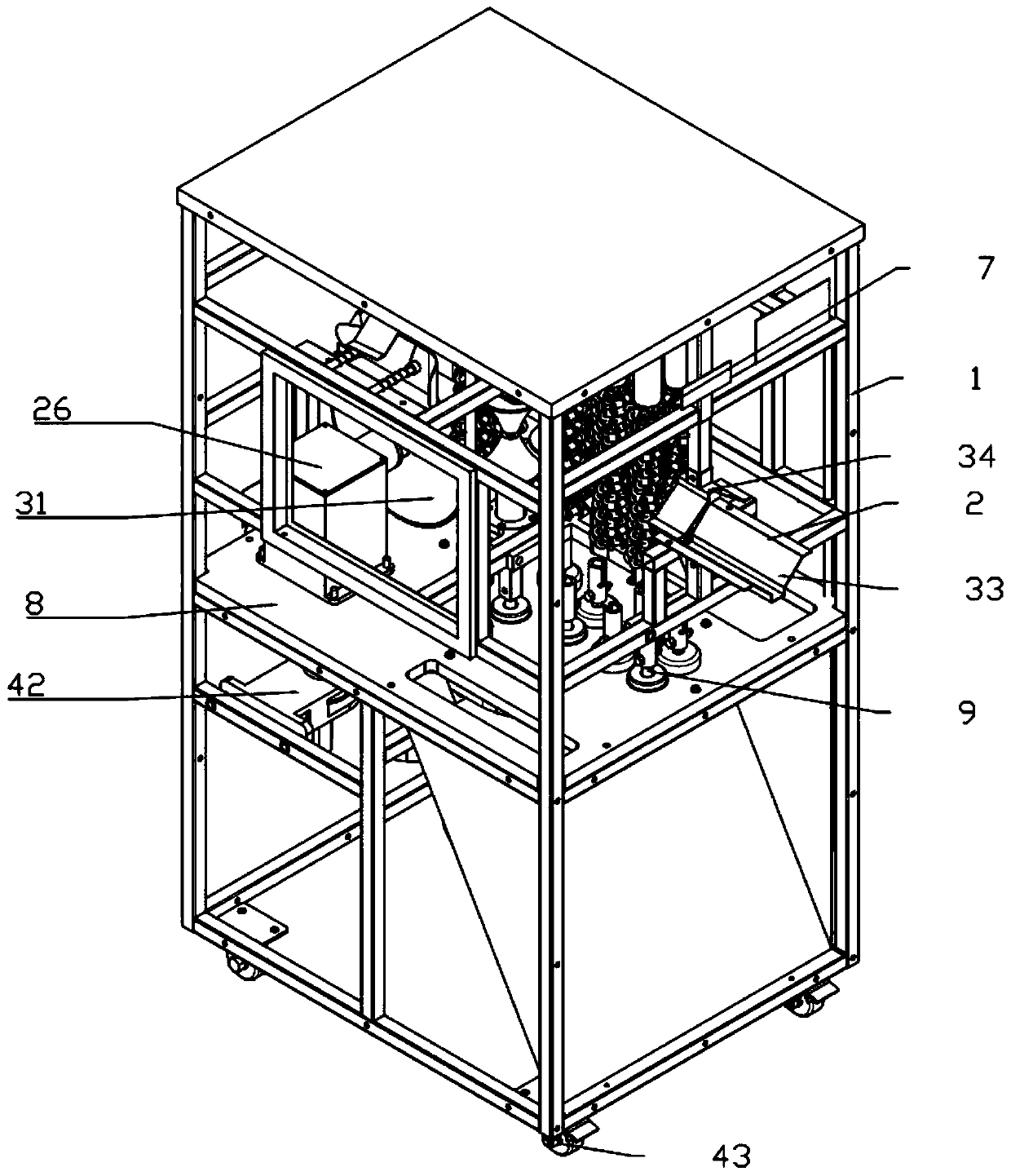

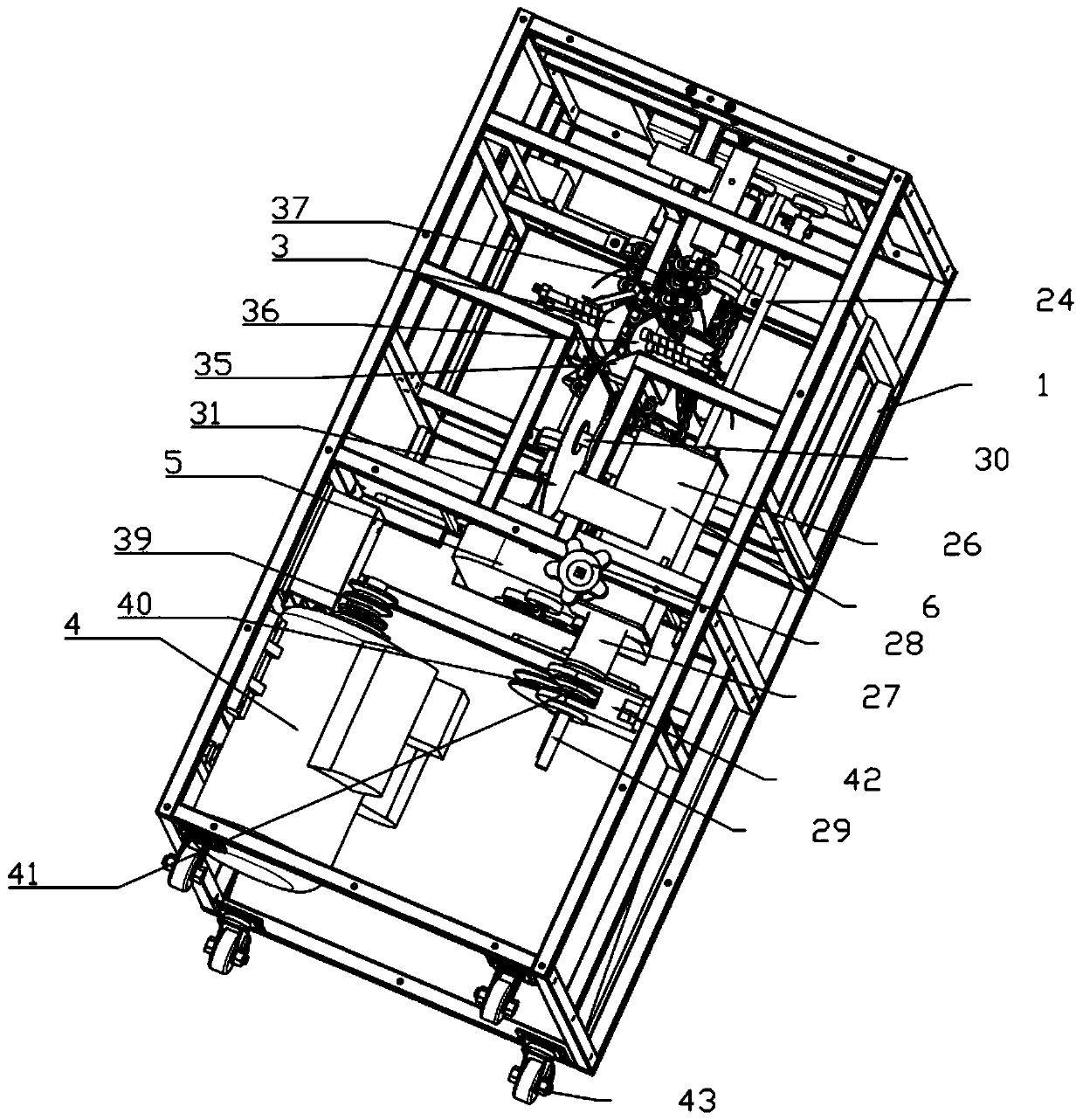

[0027] Below in conjunction with accompanying drawing, a kind of all-in-one fish killing machine of the present invention will be described in further detail.

[0028] combined with Figure 1-11 , an all-in-one machine for killing fish with open belly and back, comprising a frame 1, a fish inlet 2, a fish outlet 3, a motor 4, a gearbox 5, a blade adjustment mechanism 6 and a descaling mechanism 7, the fish inlet 2 It is arranged on the side end of the middle and upper part of the frame 1, and the fish outlet 3 is arranged on the end of the frame 1 opposite to the fish inlet 2, and the fish inlet 2 and the fish outlet 3 are located on the same horizontal plane. The extension line of the center line of the fish mouth 2 coincides with the center line of the fish outlet 3, the side end of the motor 4 is connected to the side end of the middle and lower part of the frame 1, a support plate 8 is arranged in the middle of the frame 1, and the gearbox 5 is arranged at the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com