Modular system for comprehensive treatment of ship engine waste gas

A comprehensive treatment and engine technology, applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, to achieve cost-saving installation, good absorption effect, and good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

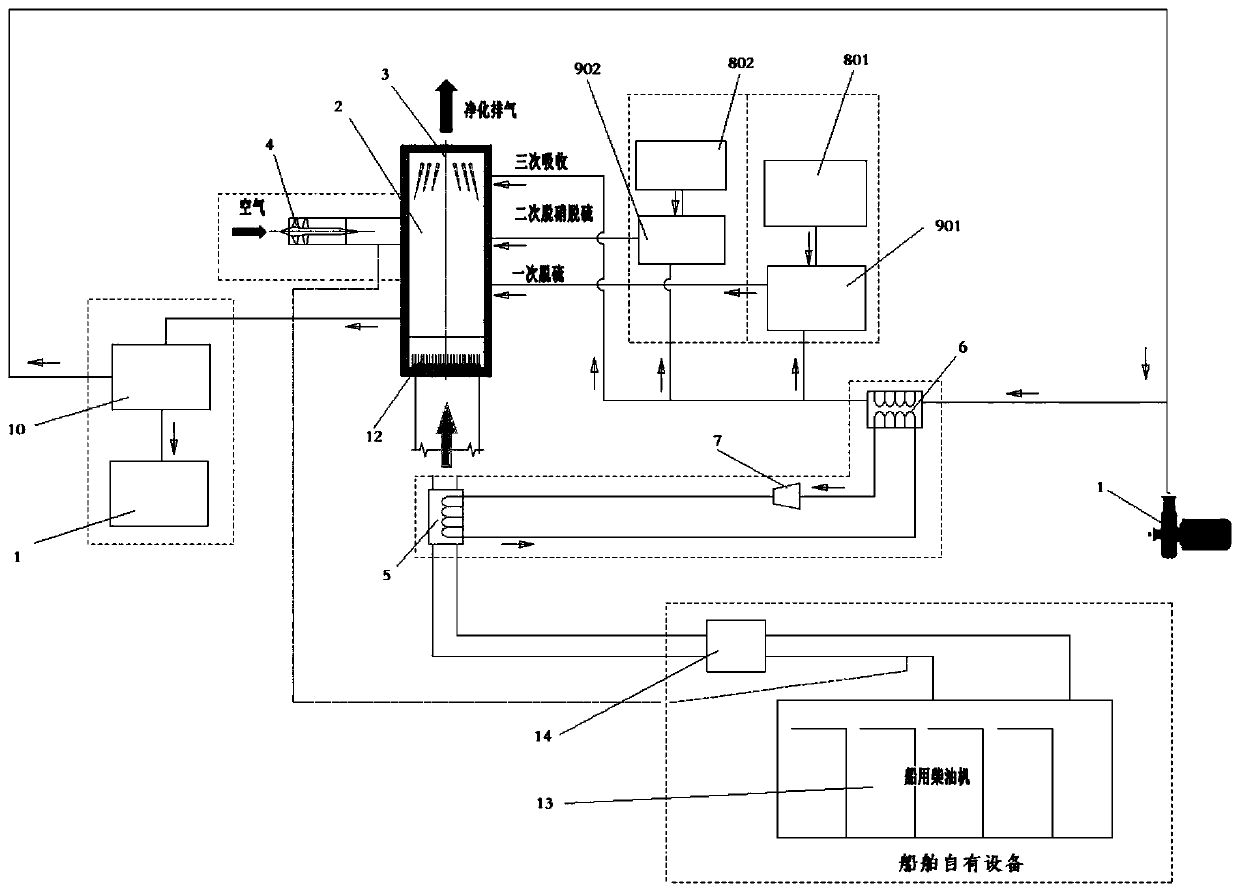

[0050]A modular marine engine exhaust gas comprehensive treatment system, including a desulfurization and denitrification module, a chemical and supply module, a chemical heating module, a waste water / slag treatment module, a system pressure adjustment module, and a seawater pump 1 as a main power device; a desulfurization and denitrification module It is the pneumatic reaction scrubber 2, and the system pressure adjustment module includes the pressure adjustment module in the pneumatic reaction scrubber and the back pressure adjustment module in the pneumatic reaction scrubber. The conditioning module consists of a piped boiler and a marine diesel engine. Among them, the seawater pump 1 is a non-pulsation plunger pump, and the plunger pump has the highest efficiency among all pump types, and the pump efficiency far exceeds that of the centrifugal pump.

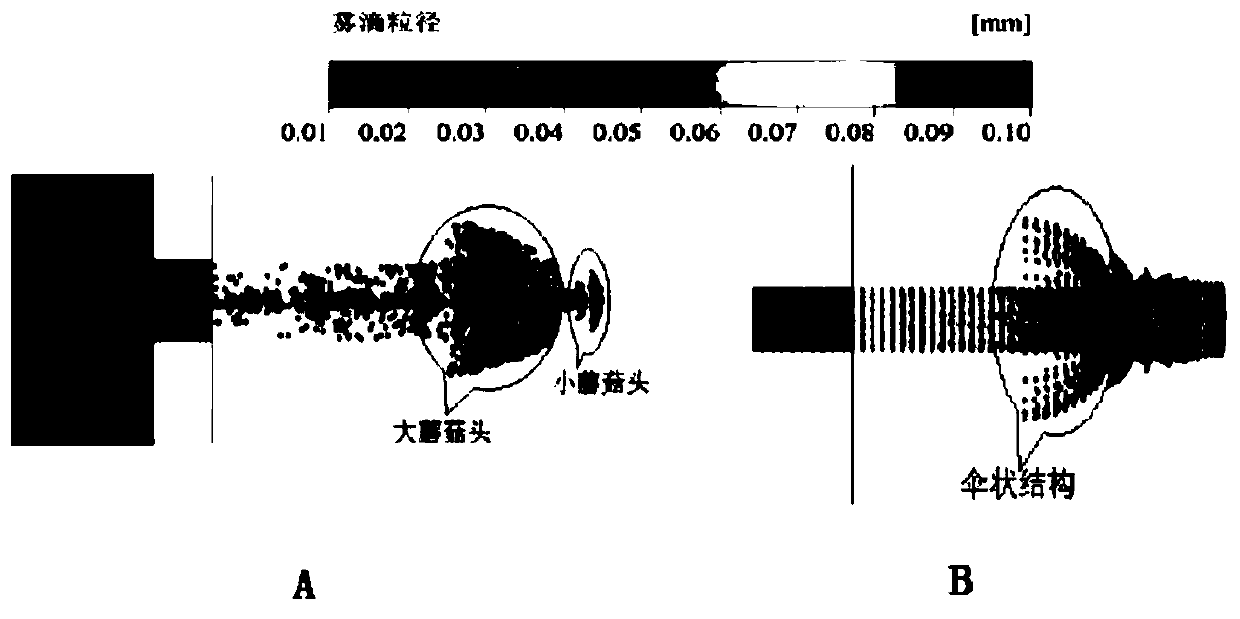

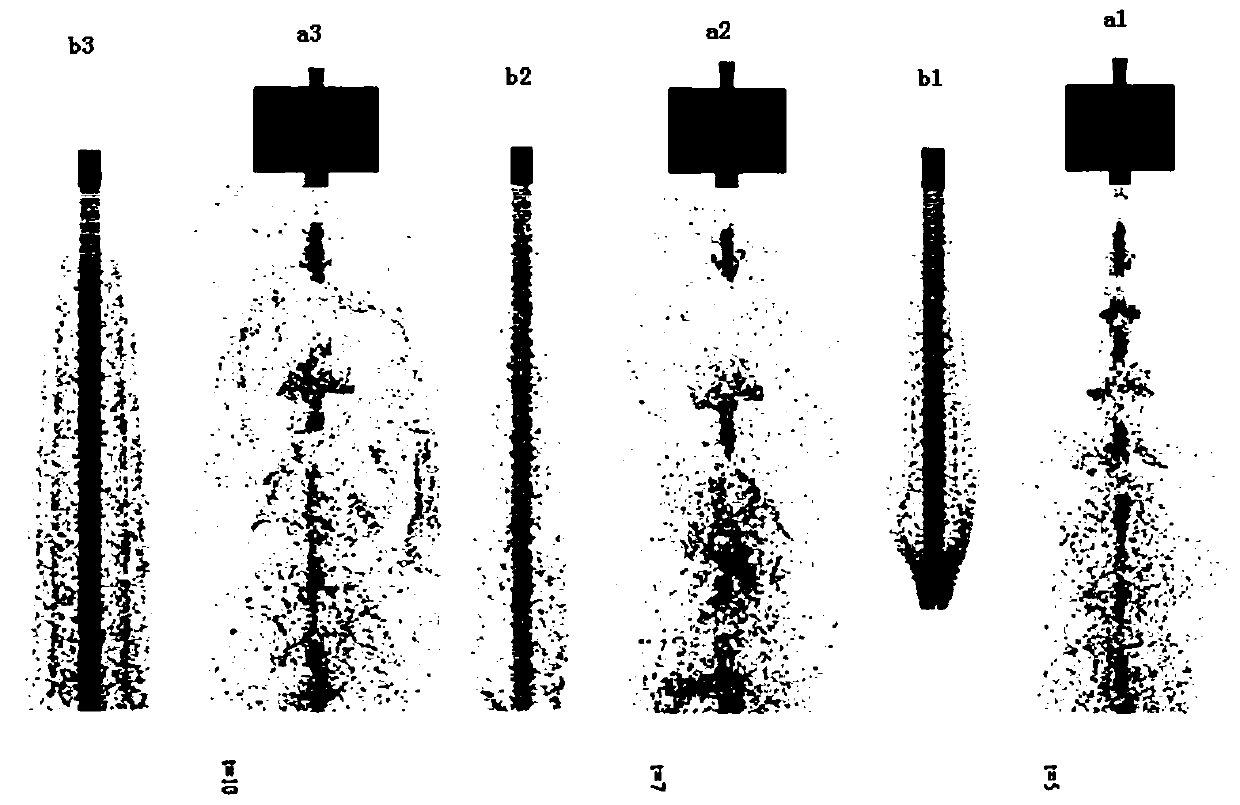

[0051] The top of the pneumatic reaction scrubber 2 is equipped with a cavitation spray system, the cavitation spray system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com