Detachable drum body for regenerated cellulose film paper rolling machine and paper rolling machine

A technology of regenerated cellulose and paper shaker, applied in metal processing and other directions, can solve the problems of waste, regenerated cellulose film cutting, large size, etc., and achieve the effects of low production cost, simple operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

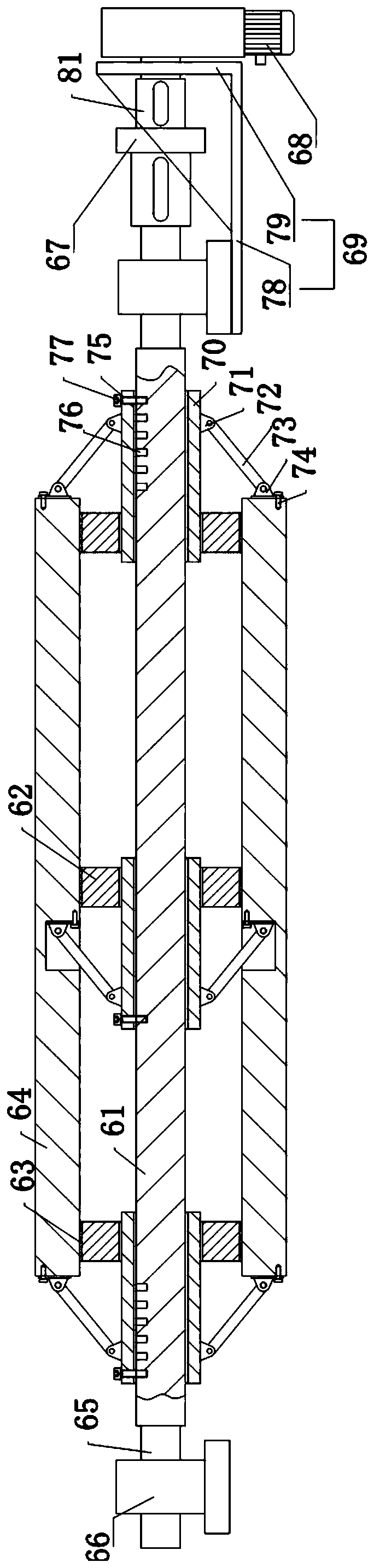

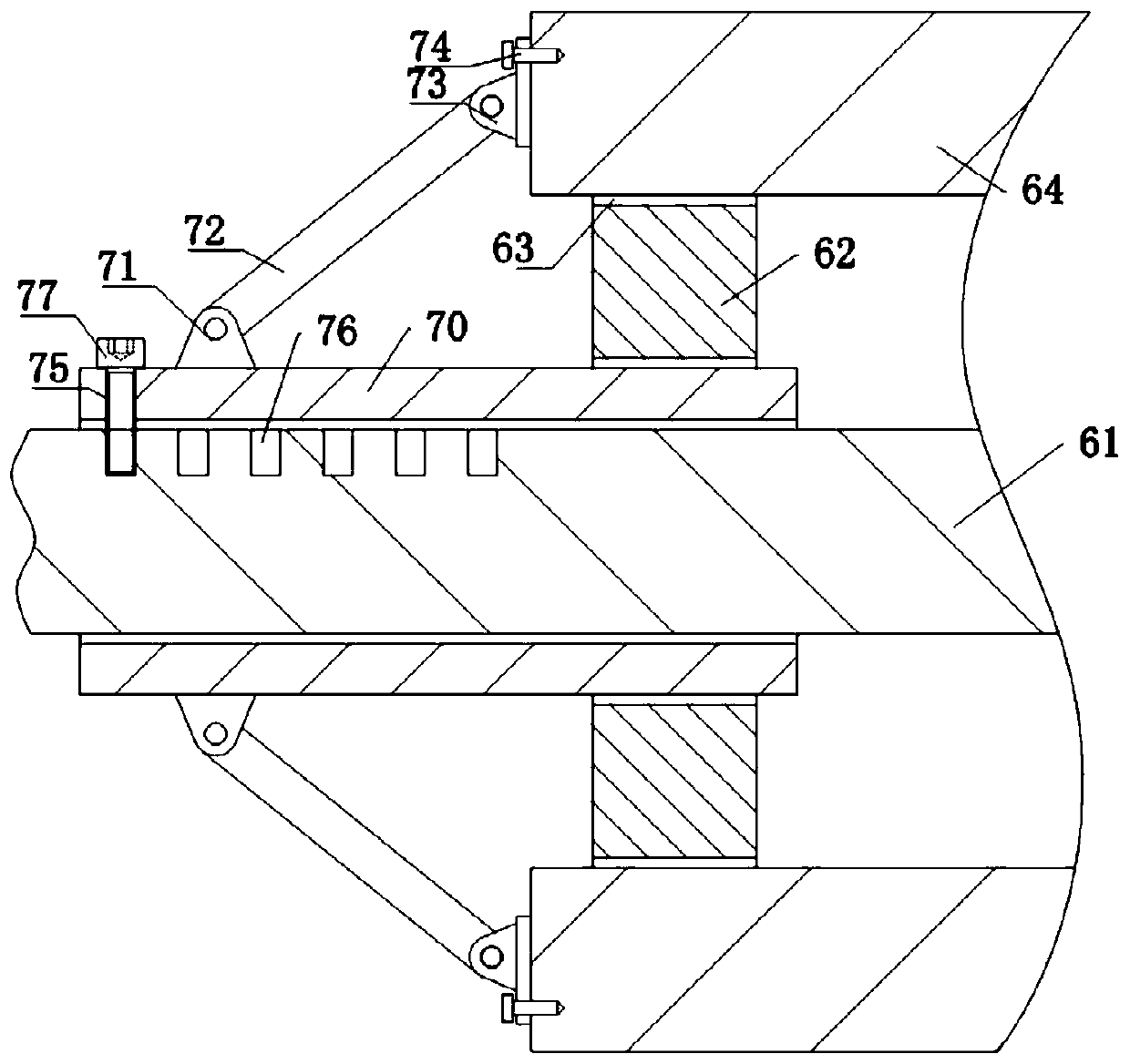

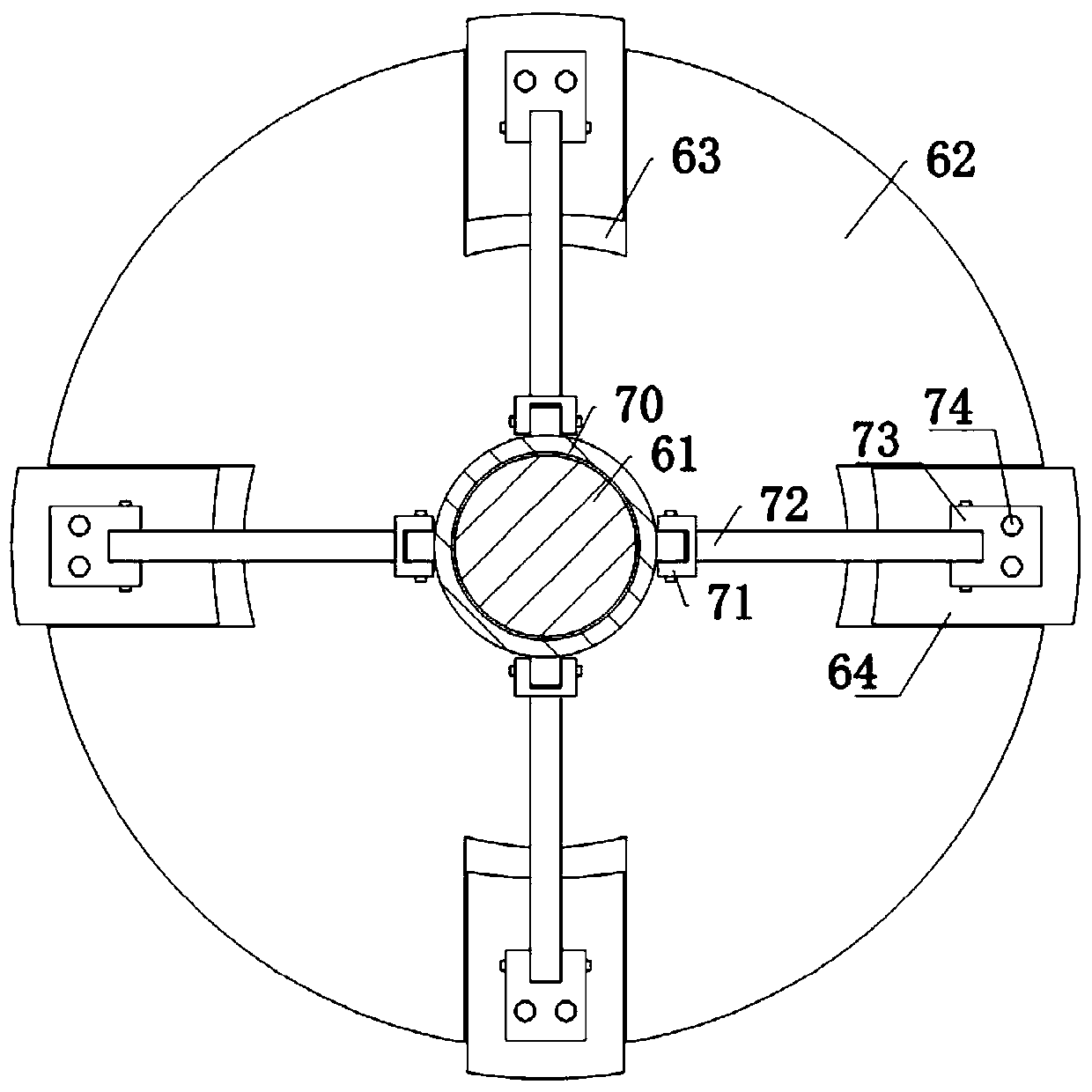

[0046] Such as figure 1 with Figure 4 As shown together, the detachable drum for the regenerated cellulose film shaker includes a horizontally arranged transmission shaft 61. Three cylindrical support plates 62 are welded on the transmission shaft 61, and each cylindrical support plate 62 is perpendicular to For the transmission shaft 61, four sliding installation grooves 63 are evenly distributed on the side wall of each cylindrical support plate 62, and a wooden square 64 is installed in each of the three horizontal sliding installation grooves 63, and each wooden square 64 All are parallel to the transmission shaft 61, an adjusting device is provided between each cylindrical support plate 62 and the wooden square 64, and both ends of the transmission shaft 61 are welded with a shaft head 65, and each shaft head 65 is equipped with a belt seat Self-aligning bearings 66. Each self-aligning bearing 66 with seat is fixed on the paper shaker. One end of the shaft head 65 extends ...

Embodiment 2

[0056] Such as Image 6 As shown, the adjustable cellophane reprocessing equipment includes a main support 1 made of steel. The main support 1 is provided with an air expansion shaft 2, a drum body 3 and a transmission controller 4 side by side. The air expansion shaft 2 and the drum body 3 are mutually parallel.

[0057] The air expansion shaft 2 is provided with a fixing device for fixing the cellophane roll 5, and both ends of the air expansion shaft 2 are respectively provided with a first bearing seat 6 and a second bearing seat 7, the first bearing seat 6 and the second bearing seat 7 They are all fixed on the main support 1, the first bearing seat 6 is provided with a screw plug assembly, and the second bearing seat 7 is provided with a brake plug assembly.

[0058] The drum body 3 includes a transmission shaft 8 parallel to the air expansion shaft 2. Three vertical support plates 9 are welded on the transmission shaft 8, and the outer side wall of each support plate 9 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com