A multi-level parallel slicing method for 3D printing models

A 3D printing, multi-level technology, applied in the field of 3D printing, can solve the problems of long time consumption, utilization of parallel processing potential, and affecting slice processing efficiency, etc., to reduce processing time consumption, reduce memory usage, and reduce hard disk I/O the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

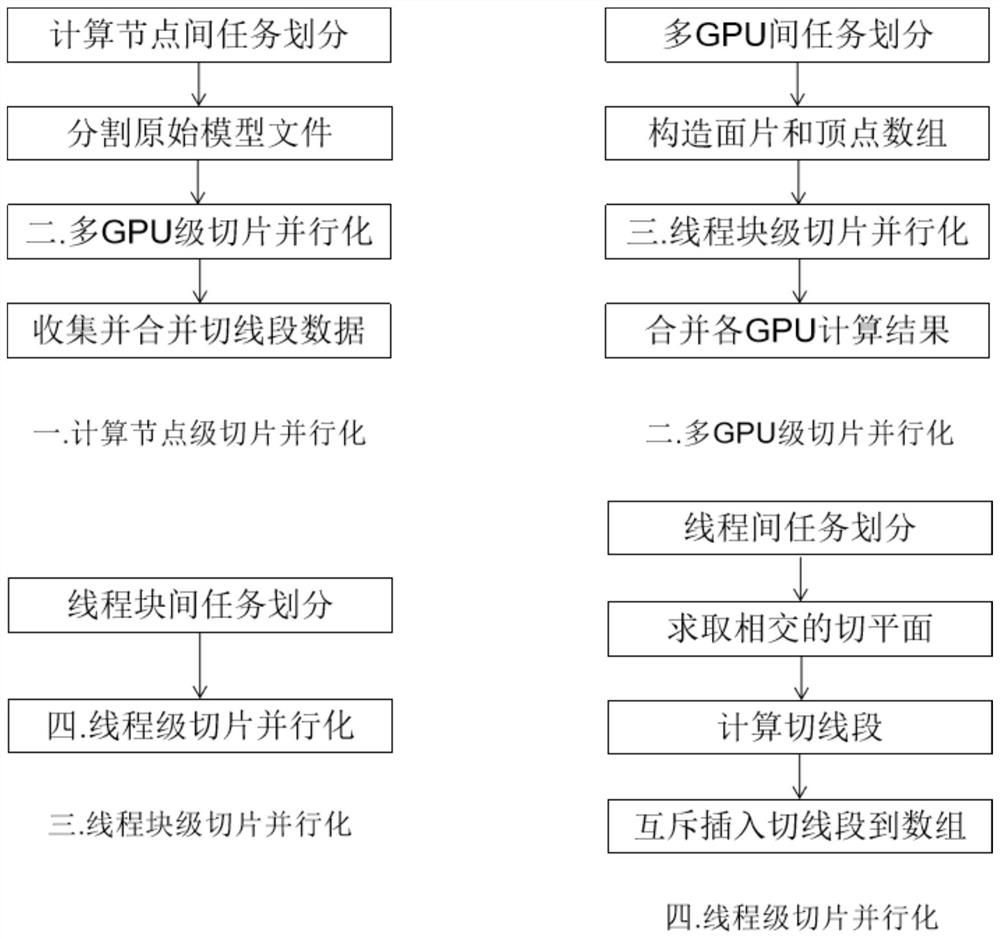

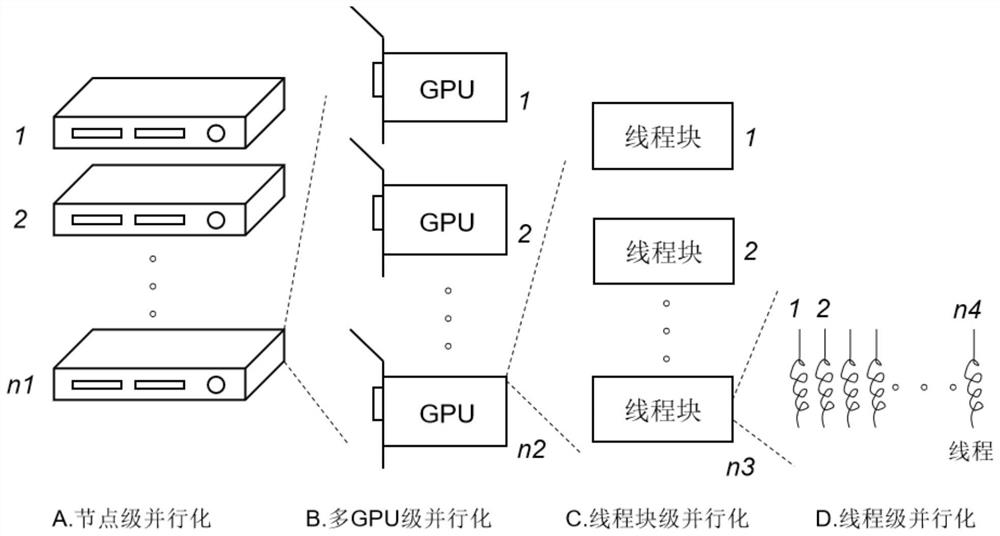

[0037] refer to Figure 1-2 , the present invention improves the slice processing speed of the three-dimensional model through a multi-level parallel method, specifically including four levels of parallelization. From a top-down perspective, they are compute node level, multi-GPU level, thread block level, and thread level.

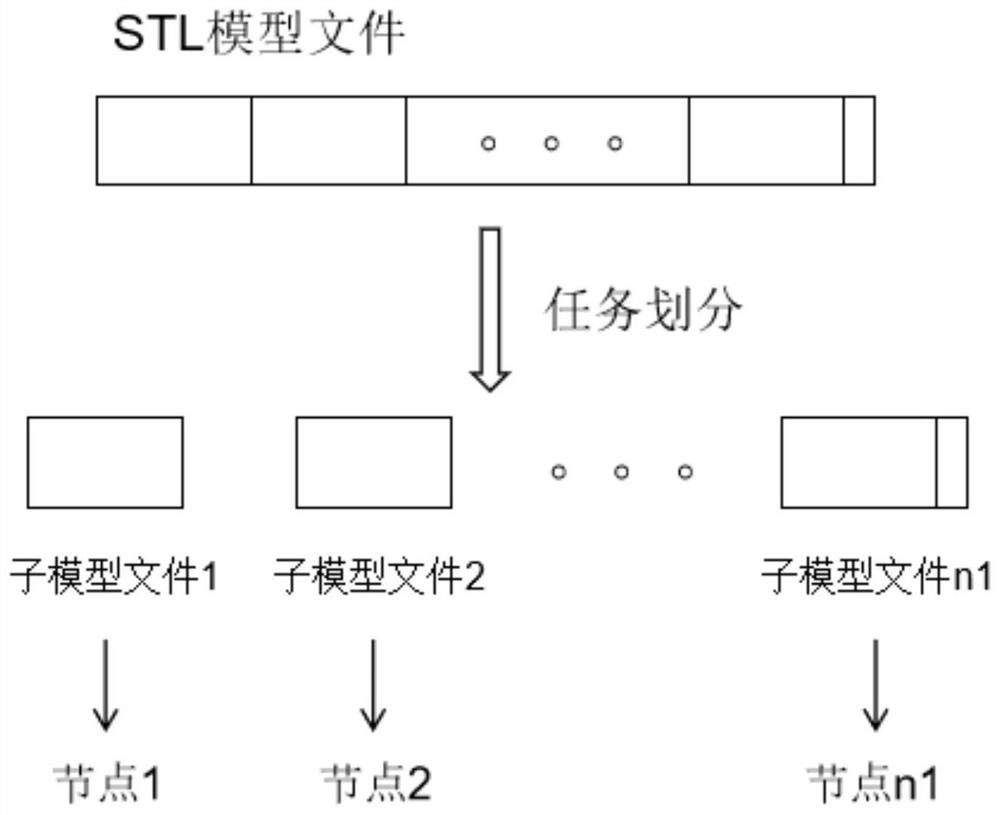

[0038] Step 1: Perform computing node-level slicing parallelization. In the cluster, divide tasks between computing nodes using facets as the basic unit, divide the original model file according to the division results, and perform step 2. After completion, collect and merge tangents between computing nodes segment data.

[0039] The division of tasks between computing nodes refers to dividing the original model file in a continuous and equal manner with the patch as the basic unit, and assigning the remainder after the equal division to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com