Moving mechanism of soft-belt-free slewing bearing intermediate frequency quenching inductor

A quenching inductor and slewing bearing technology, applied in quenching device, process efficiency improvement, furnace type and other directions, can solve the problem of center correspondence that cannot be slewing bearing, and achieve the goal of improving accuracy, simple design structure and improving quenching quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

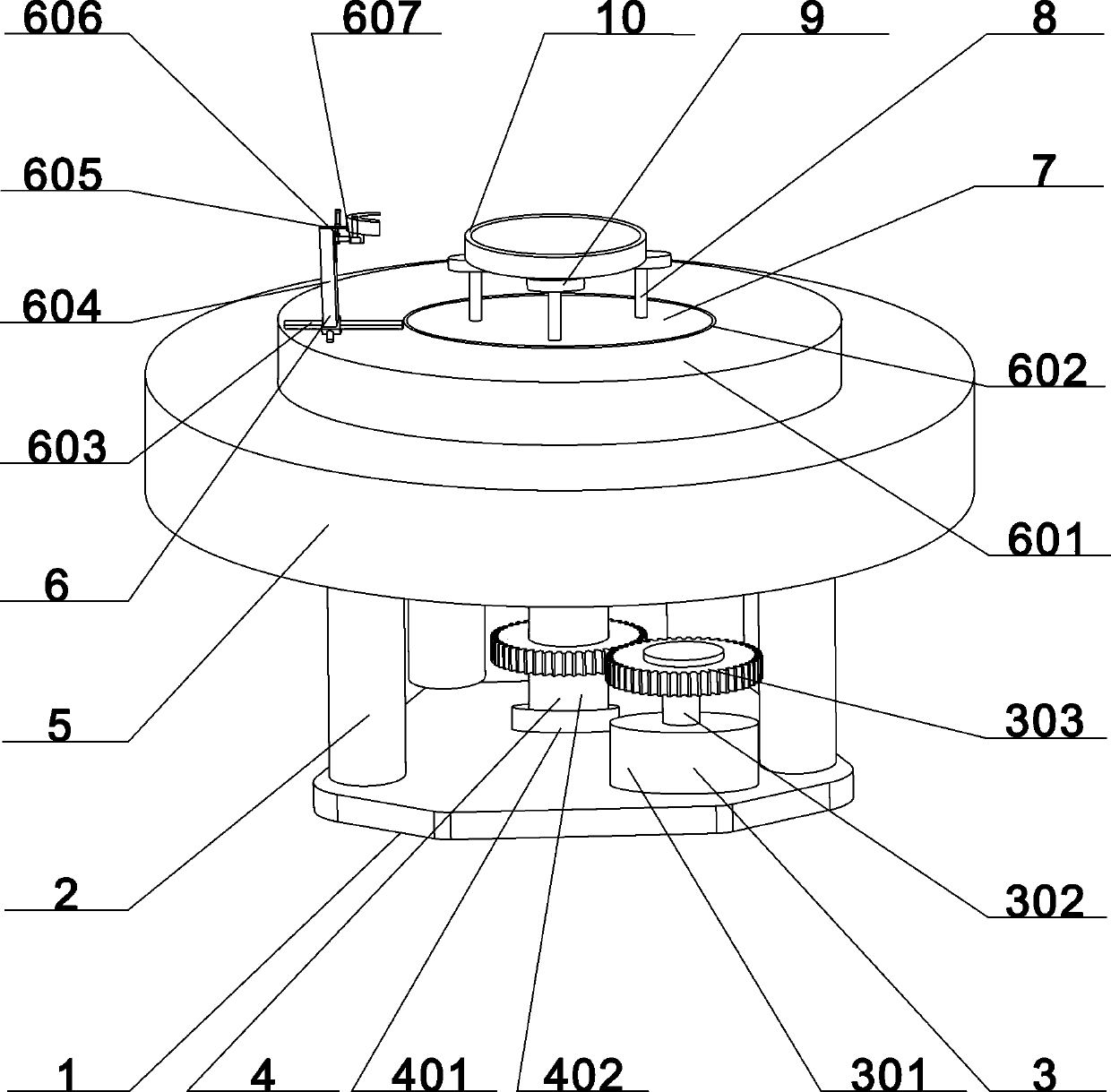

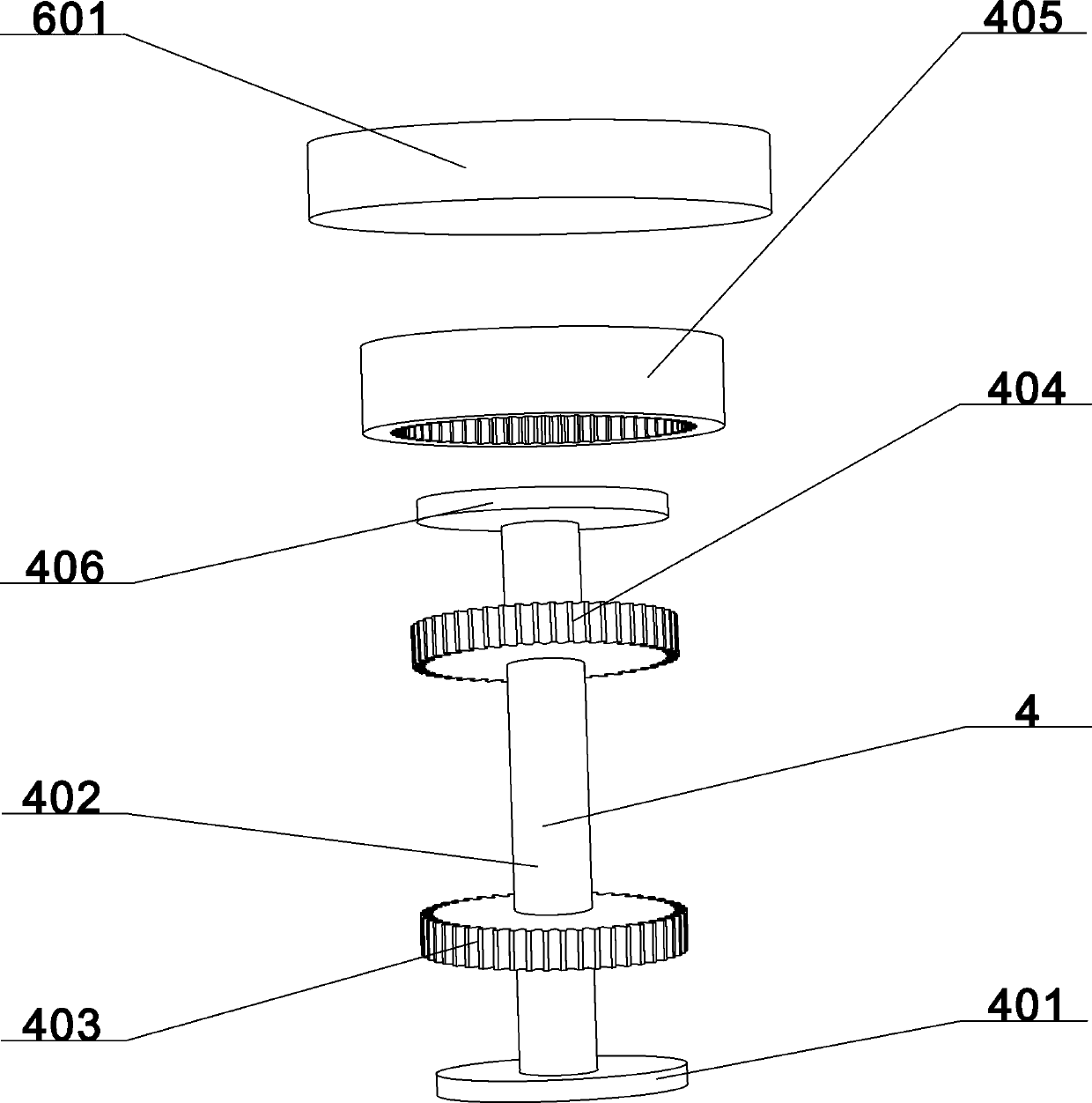

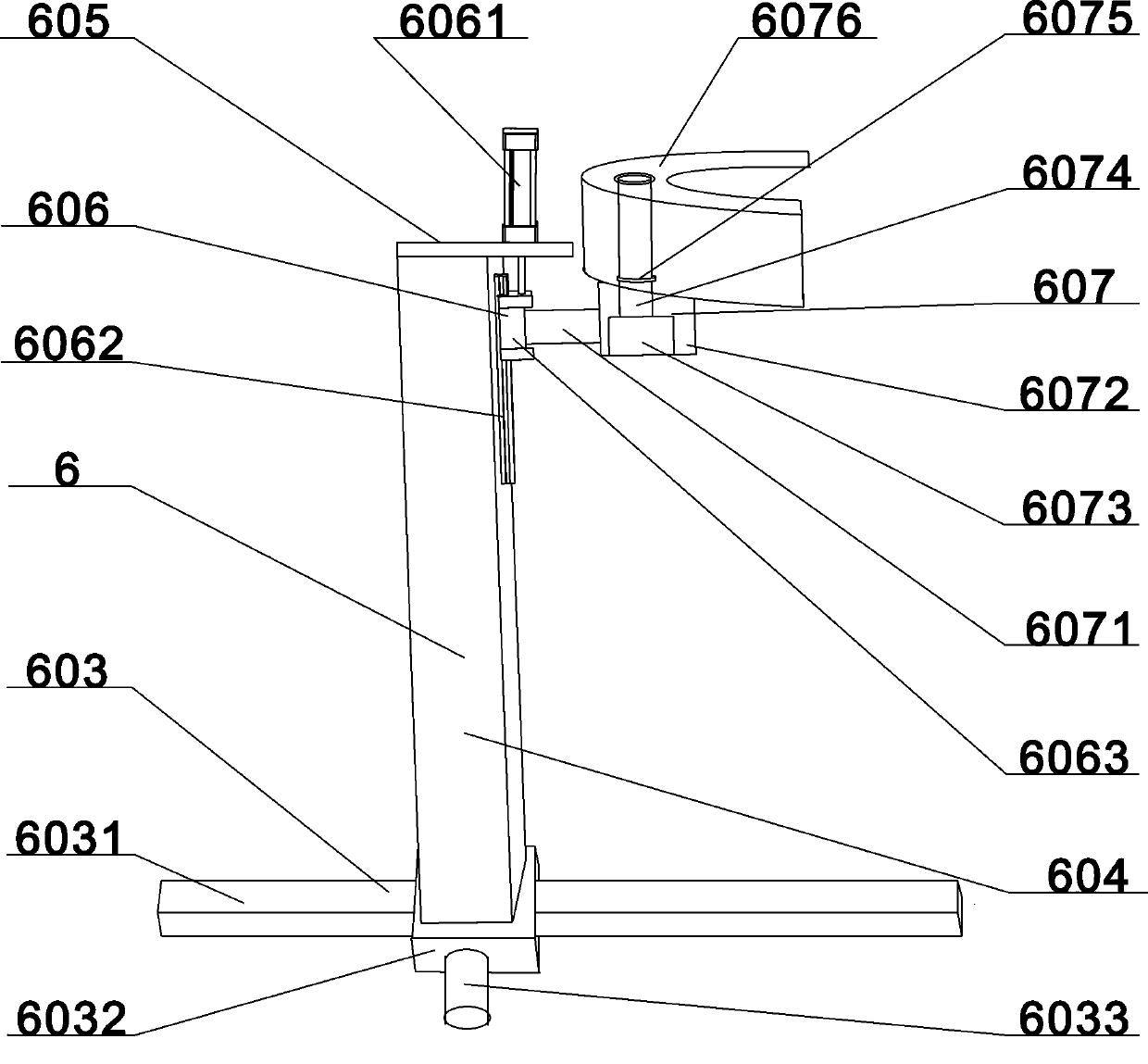

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] As shown in the figure, a motion mechanism without a soft belt slewing bearing intermediate frequency quenching sensor includes a base plate 1, a support column 2, a driving device 3, and a driven device 4; the base plate 1 is fixed on the bottom of the support column 2 position, the support column 2 is symmetrically arranged at the four corners of the bottom plate 1; the driving device 3 is fixed at the right front end of the bottom plate 1, and the driven device 4 is fixed at the rear left side of the driving device 3. The driving device 3 is used to provide rotational power to the driven device 4; the support disc 5 is fixedly arranged at the upper position of the four support columns 2; the induction hardening device 6 is fixedly arranged at the upper center position of the support disc 5, The induction harden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com