Hole cavity diameter measuring device and measuring method

A technology of diameter measurement and measurement device, applied in the field of geometric measurement, can solve the problems of low measurement accuracy and inconvenient operation, and achieve the effects of accurate measurement results, easy portability, and ensuring precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

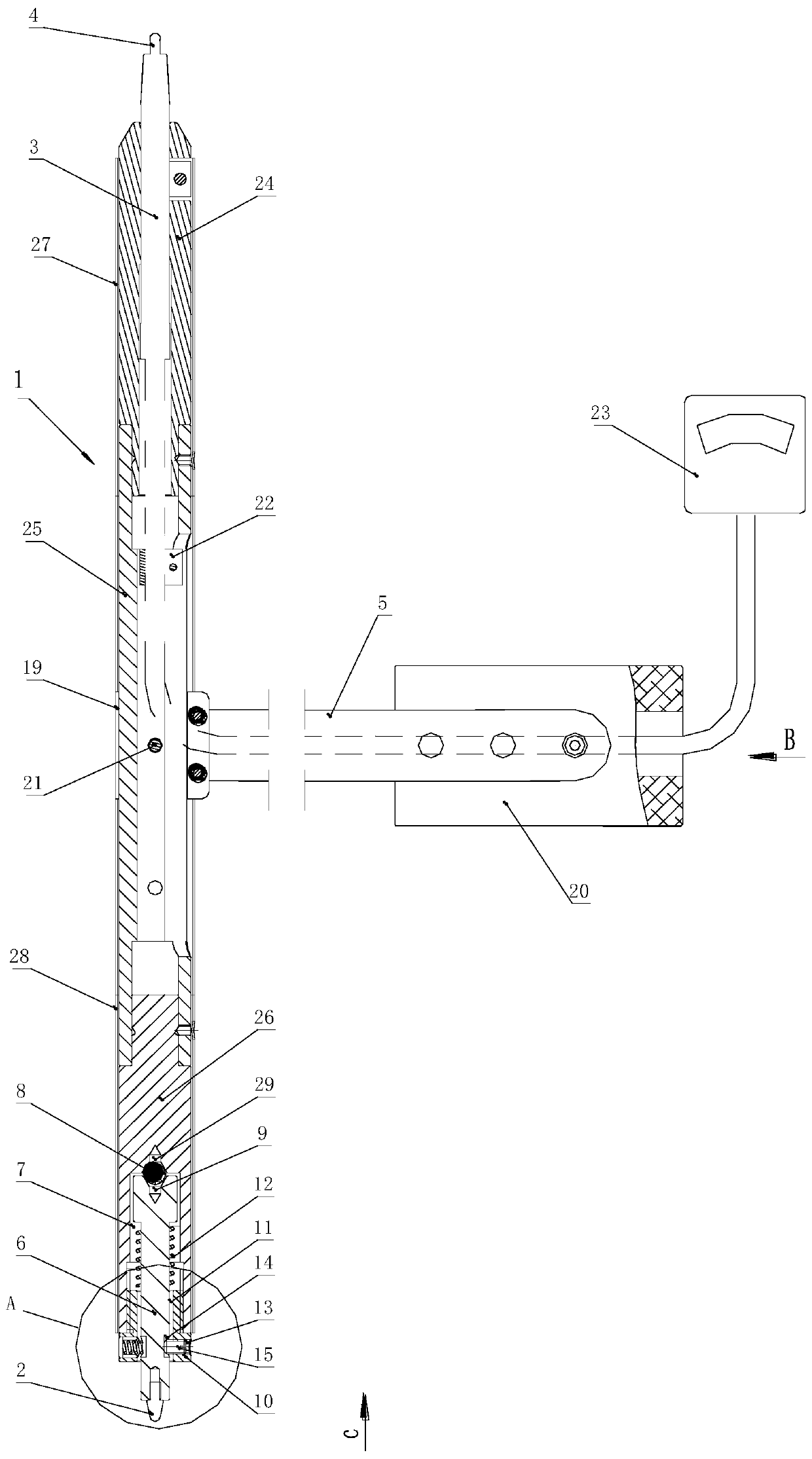

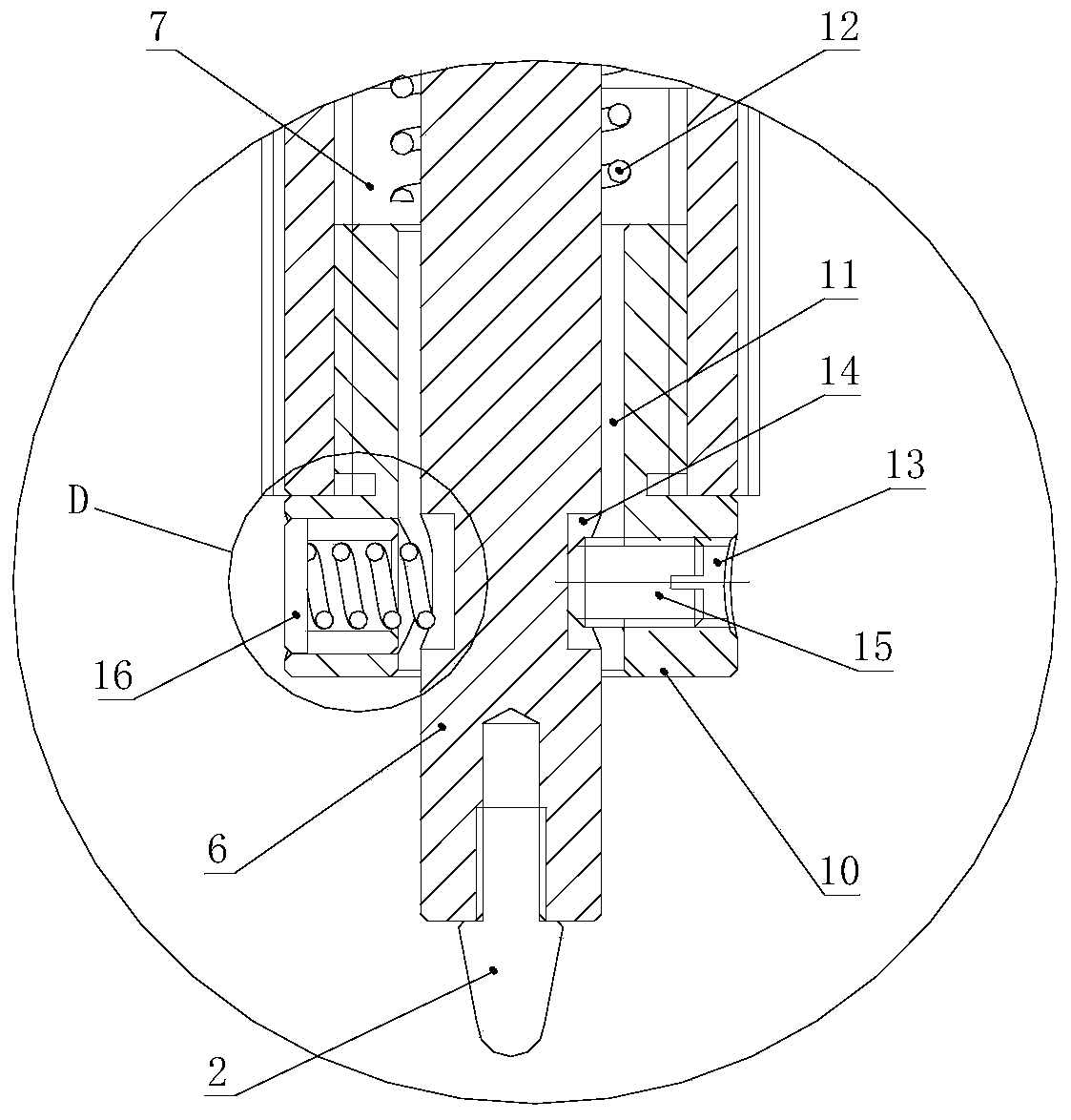

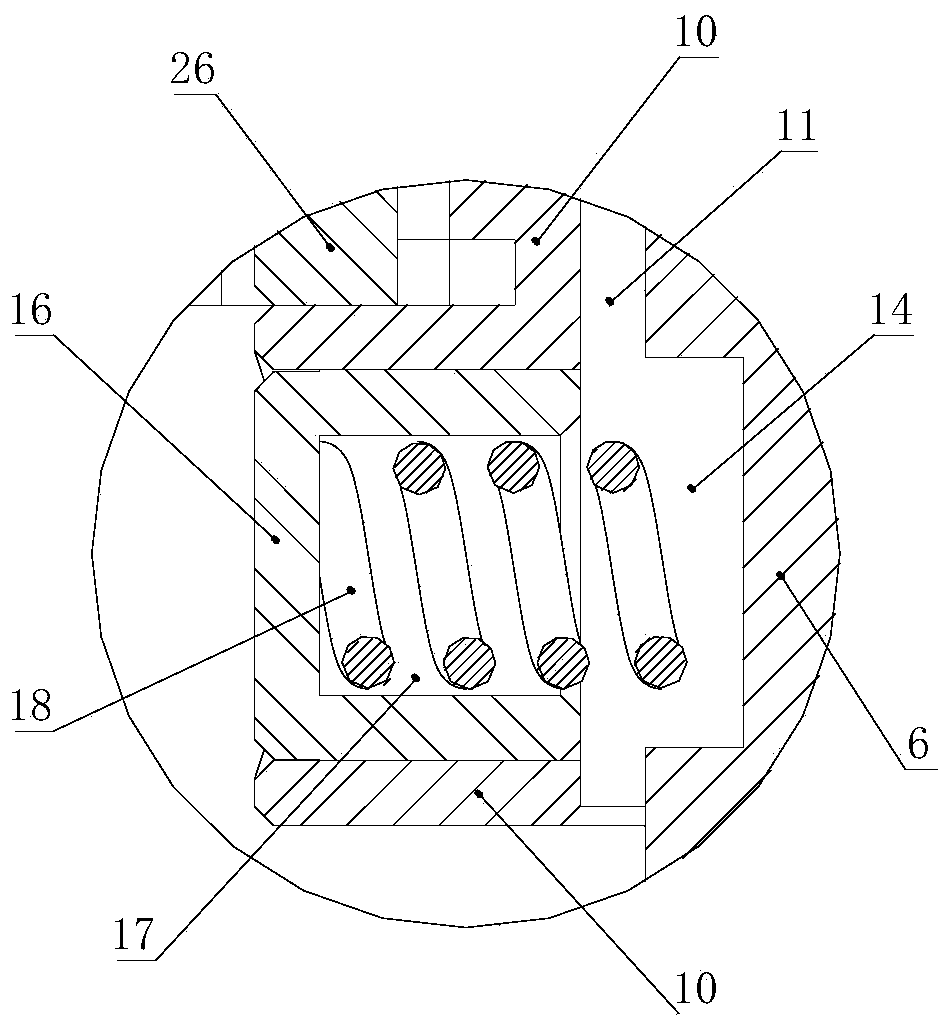

[0033] A cavity diameter measuring device comprises a measuring rod 1, a ball head 2 is provided at one end of the measuring rod 1, and a displacement sensor 3 is provided at the other end of the measuring rod 1. In this embodiment, the measuring rod 1 is composed of a front cylinder 24, a middle cylinder 25 and a rear cylinder 26, specifically:

[0034] The front cylinder 24 is a hollow divided circular tube structure, and its upper end is provided with an opening clamp, and the displacement sensor 3 can be fixed by tightening the opening clamp with a screw, which is convenient for fixing and replacing the displacement sensor 3, and is also convenient for adjusting the position of the displacement sensor 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com