High-precision rapid automatic focusing mechanism

An automatic focusing and high-precision technology, which is applied in the direction of focusing devices, cameras, installations, etc., can solve the problems of slow focusing speed, large return gap, and cannot meet the fast and high-precision focusing function, and achieve the effect of fast and accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

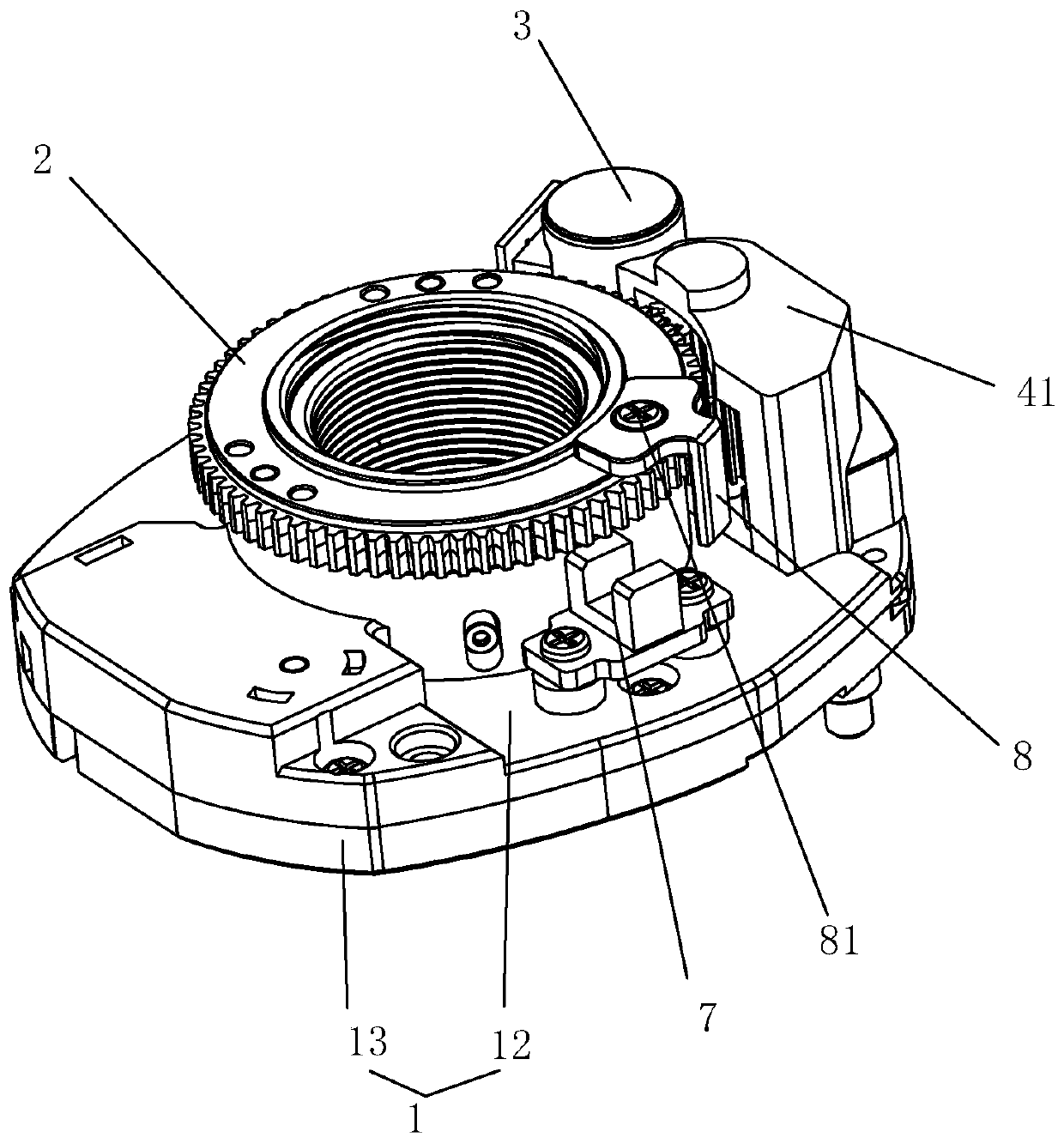

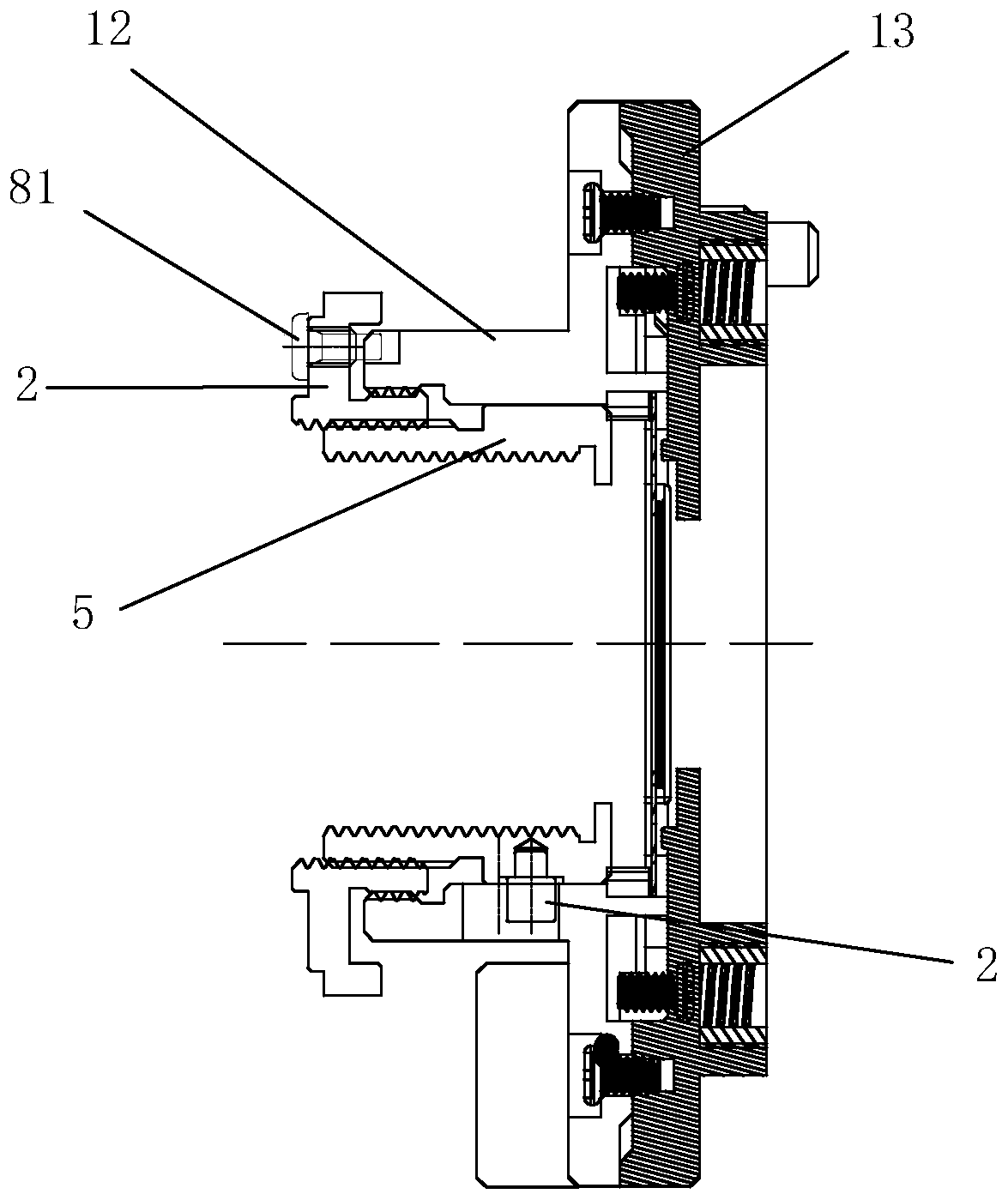

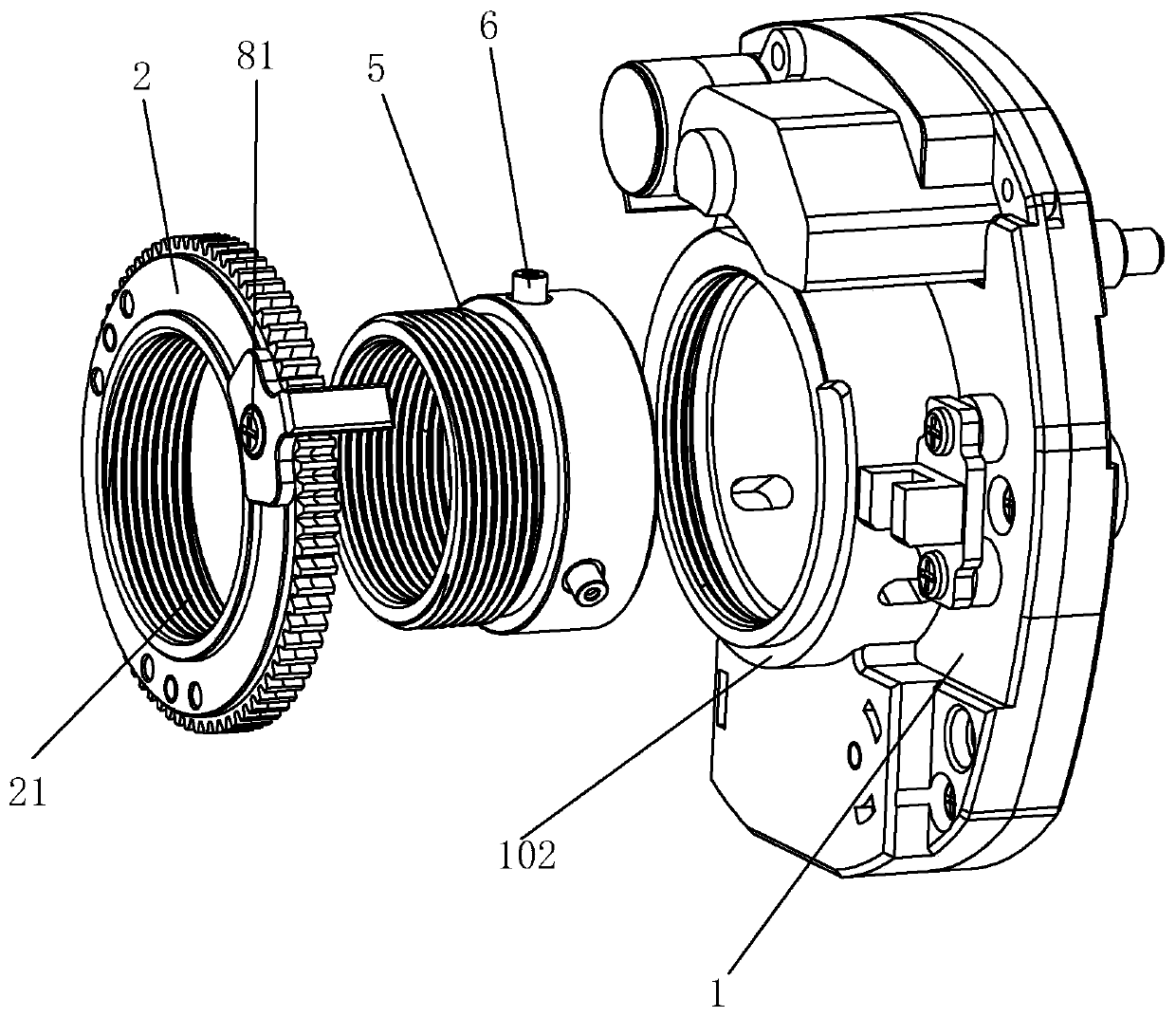

[0026] Example: see Figure 1 to Figure 6 , a high-precision fast auto-focus mechanism, including a fixed base 1, multi-head braces 2, a stepping motor 3 and a gear set 4, the fixed base 1 has a cylindrical portion 11 to accommodate the connecting lens mount 5, the cylindrical portion 11 is connected to the connecting lens The seat 5 is equipped with an axial limit structure, and the peripheral wall of the cylindrical part of the fixed seat 1 is provided with more than one straight groove 101 along the axial direction, and the connecting lens seat 5 is provided with a guide nail 6 matched with the straight groove. The straight groove 101 cooperates to form an axial limit structure; the multi-head dental cover 2 is arranged at the port of the cylinder part of the fixed seat 1, the multi-head dental cover 2 has an interface ring 21 and a gear outer ring 22, and the interface ring 211 has an external connection part and an internal connection part. The part is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com