Cloud intelligent production optimization scheduling online decision-making method and system based on case-based reasoning

A technology for intelligent production and optimal scheduling, applied in control/regulation systems, general control systems, comprehensive factory control, etc., can solve problems such as difficulty in realizing real-time optimization of cloud-based intelligent production scheduling process, difficulty in meeting green manufacturing, etc., and achieve effective reuse , the effect of saving resources and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be further described below in conjunction with specific drawings and embodiments.

[0037] As we all know, on the one hand, because the cloud intelligent production optimization scheduling process is a semi-structured and unstructured problem, it is difficult to optimize it with an accurate mathematical model; on the other hand, a large number of production scheduling cases have been accumulated in the cloud platform The use of CBR technology can not only make good use of these ready-made case knowledge to help solve the current cloud intelligent production scheduling problem to be decided, but also greatly improve the optimization efficiency.

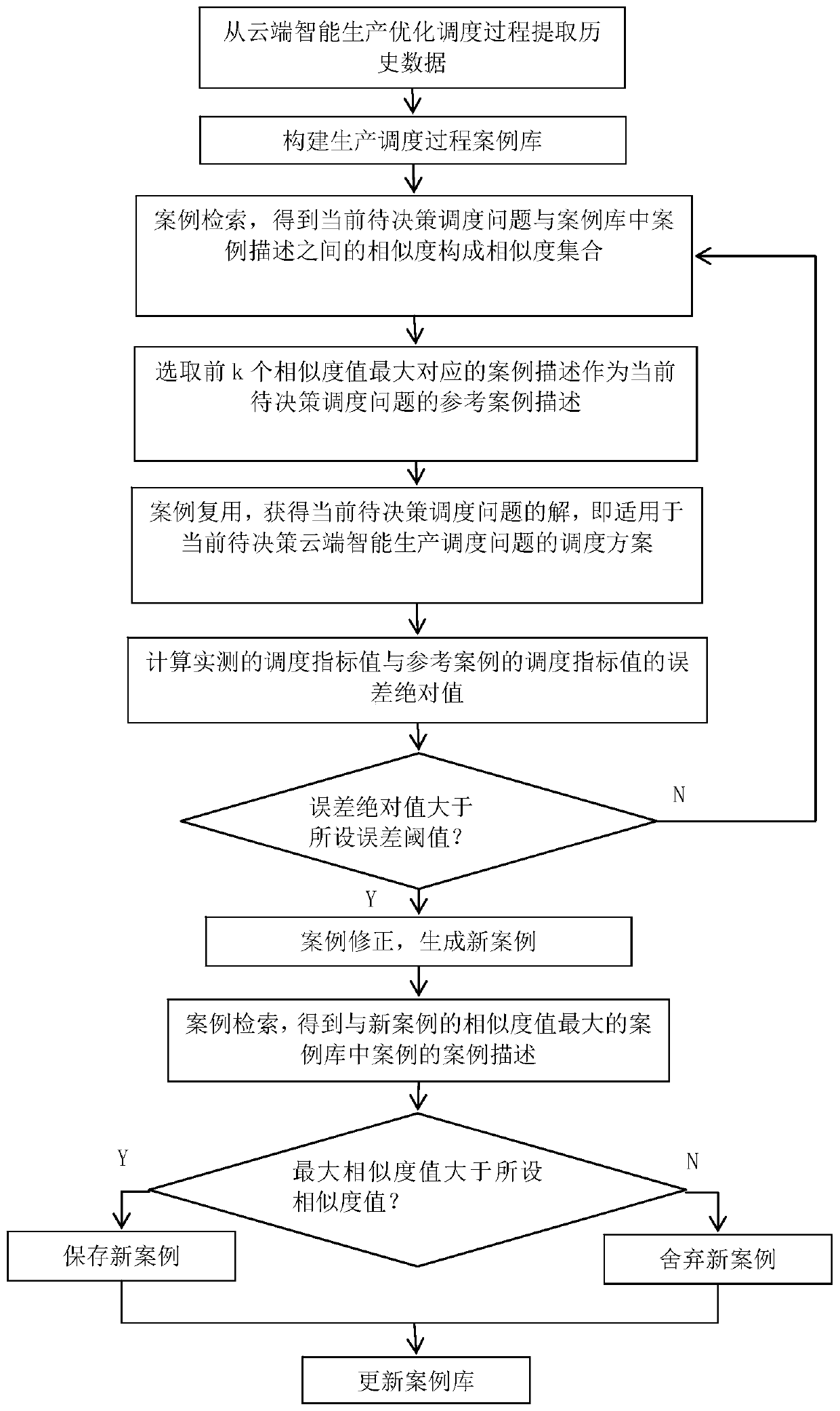

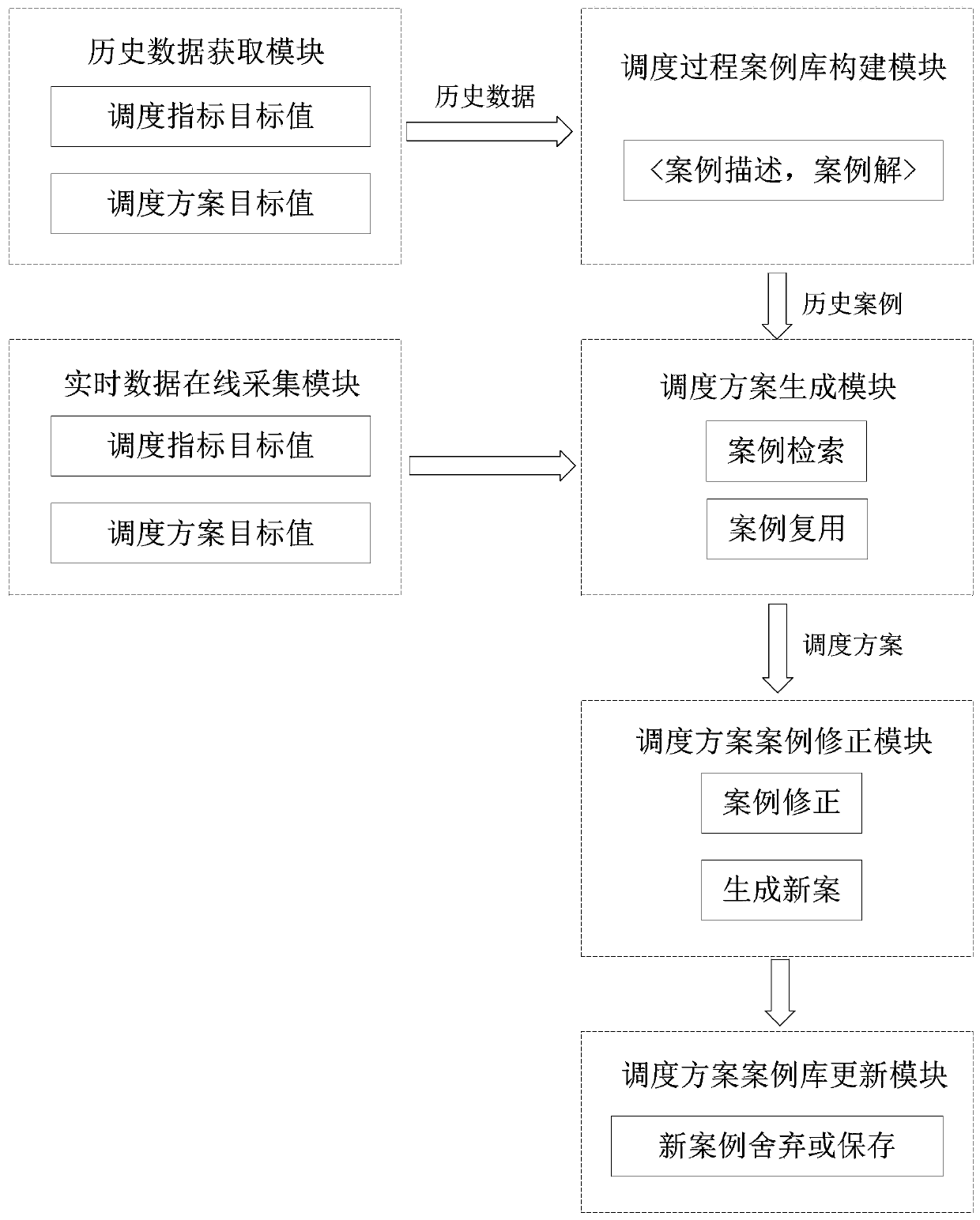

[0038] Based on the above principles, an embodiment of the present invention proposes an online decision-making method for cloud intelligent production optimization scheduling based on case reasoning, using the historical data of the cloud intelligent production scheduling process to construct a scheduli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com