A liquid-cooled cable for a new energy electric vehicle liquid-cooled charging socket

A technology for electric vehicles and charging sockets, applied in electric vehicle charging technology, electric vehicles, power cables, etc., can solve problems such as fires, burning vehicles, causing accidents, etc., and achieve long-term reliable work, increase charging power, and shorten charging time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] At present, the country has standard definitions for electric vehicle charging cables and multiple cables in the charging socket. In addition to the two charging cables DC+ and DC-, there are also multiple weak current cables such as signal lines and communication lines. The present invention Mainly for the DC+ and DC- two charging cables with large charging current and high heat generation.

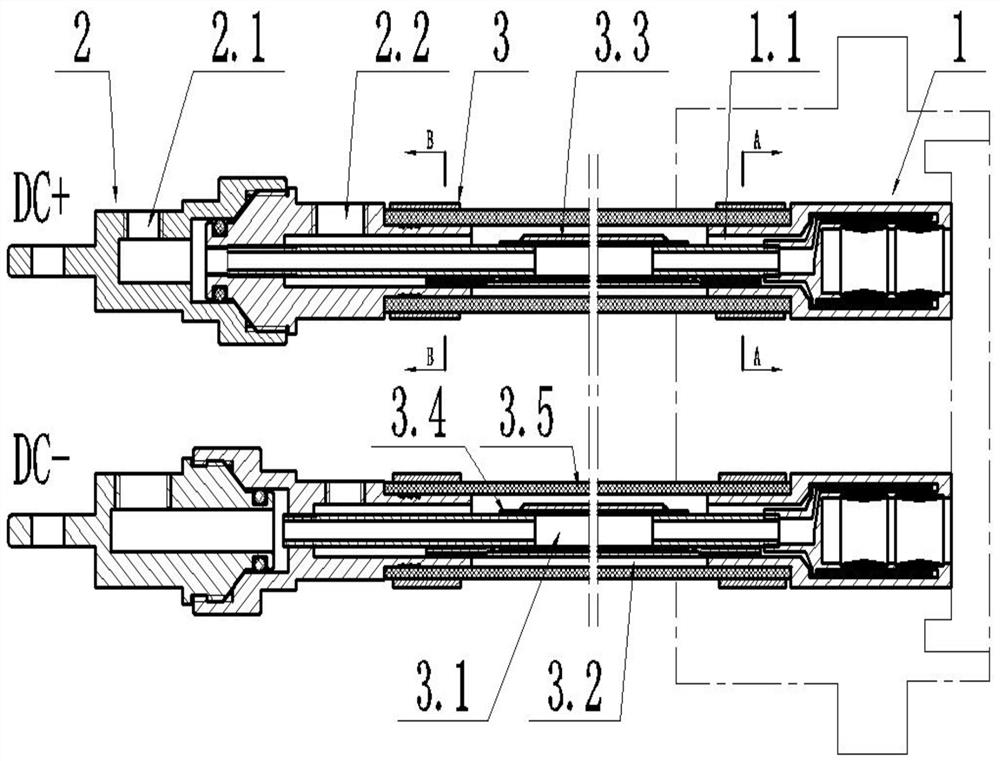

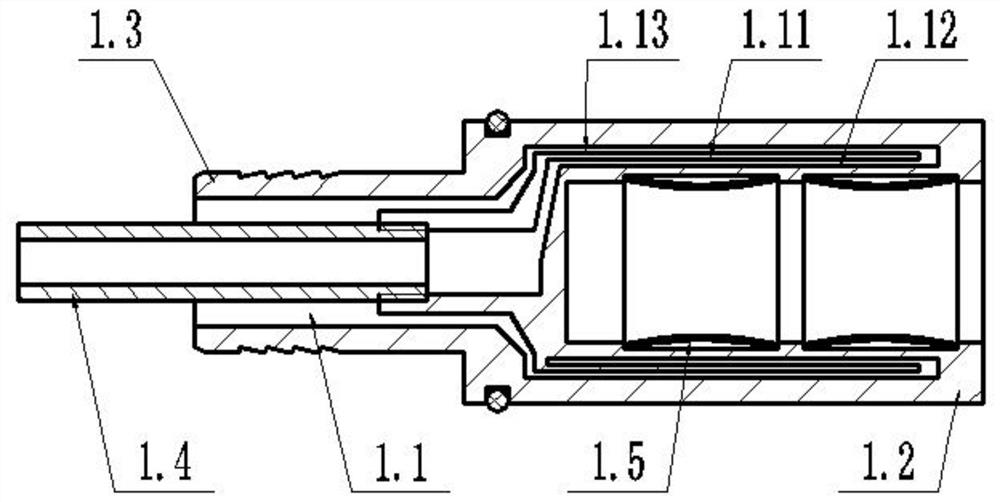

[0037] figure 1 Shown is a schematic structural diagram of a liquid-cooled cable for a new energy electric vehicle liquid-cooled charging socket of the present invention, including two liquid-cooled jacks 1, DC+ and DC-, arranged in the charging socket of an electric vehicle, and also includes a battery pack Two liquid-cooled electrodes 2 connected to DC+ and DC- poles, and two electrodes respectively connected between DC+ liquid-cooled jack 1 and DC+ liquid-cooled electrode 2, DC-liquid-cooled jack 1 and DC-liquid-cooled electrode 2 A liquid-cooled cable3. Wherein, the liquid-c...

Embodiment 2

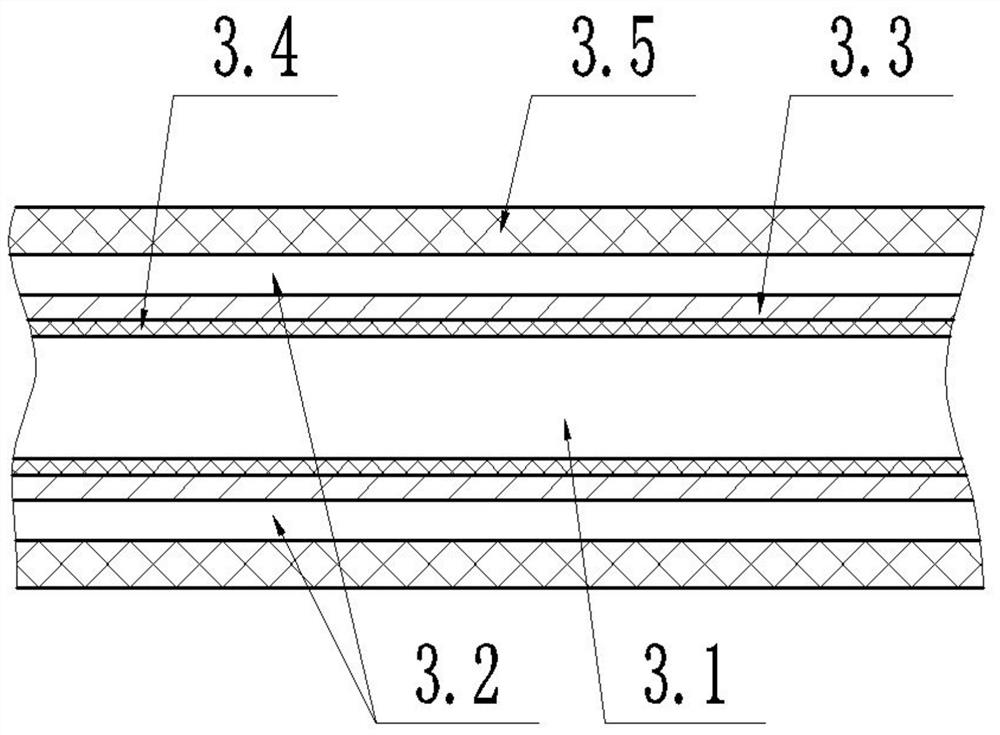

[0055] As described in Embodiment 1, the liquid-cooled cable for the liquid-cooled charging socket of a new energy electric vehicle is different from Embodiment 1 in that: Figure 9 As shown, the flexible wire 3.3 runs through the insulating sleeve 3.5, and the cooling liquid inner tube 3.4 is also installed in the insulating sleeve 3.5. The inner cavity of the cooling liquid inner tube 3.4 is the cooling liquid inner channel 3.1, and the cooling liquid inner The cavity between the tube 3.4 and the insulating sleeve 3.5 is the cooling liquid outer channel 3.2. One end of the cooling liquid internal channel 3.1 connected to the liquid-cooled electrode 2 is connected to the liquid inlet 2.1, and one end connected to the liquid-cooled jack 1 is connected to the communication cavity 1.1. One end of the cooling liquid outer channel 3.2 connected to the liquid-cooled electrode 2 is connected to the liquid outlet 2.2, and one end connected to the liquid-cooled jack 1 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com