Auxiliary machine for manufacturing and forming anchor rod for power accessory equipment

A technology for auxiliary machinery and accessories, which is applied in the field of auxiliary machinery for making wire rods for electrical accessories and equipment. It can solve the problems of high production cost, poor continuity, and low degree of automation, and achieve the effect of beautiful and consistent welding length and improved economic practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

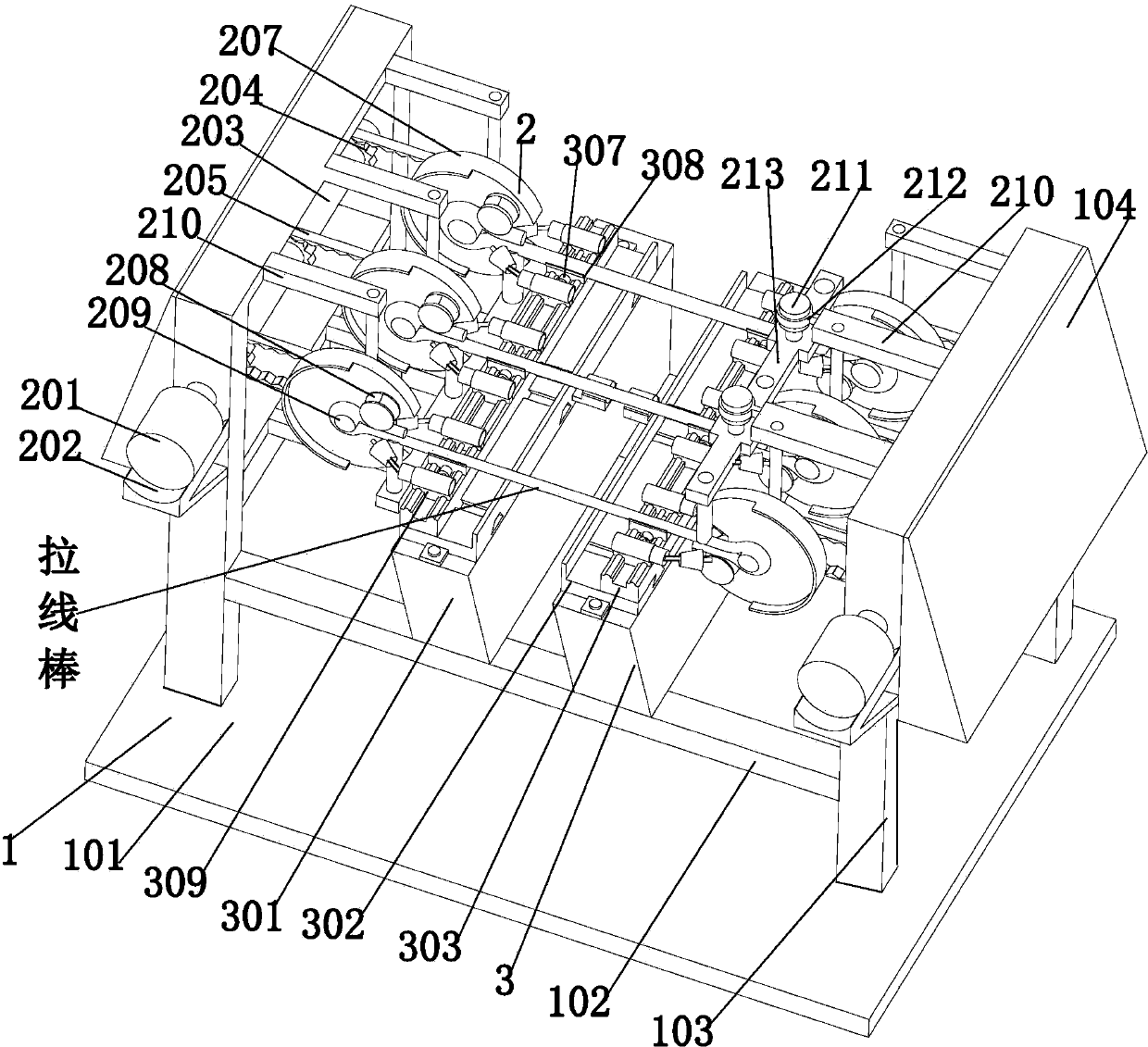

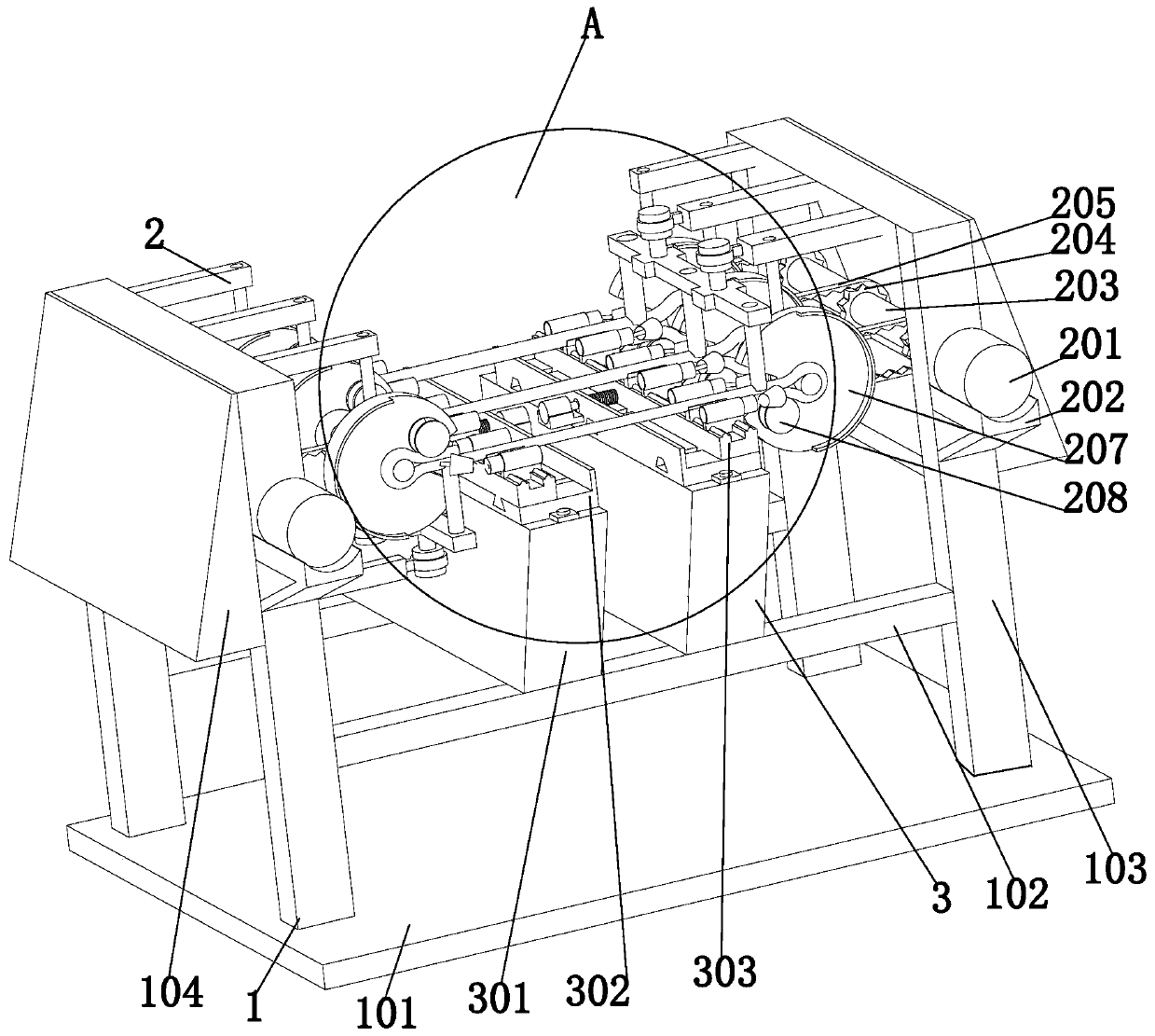

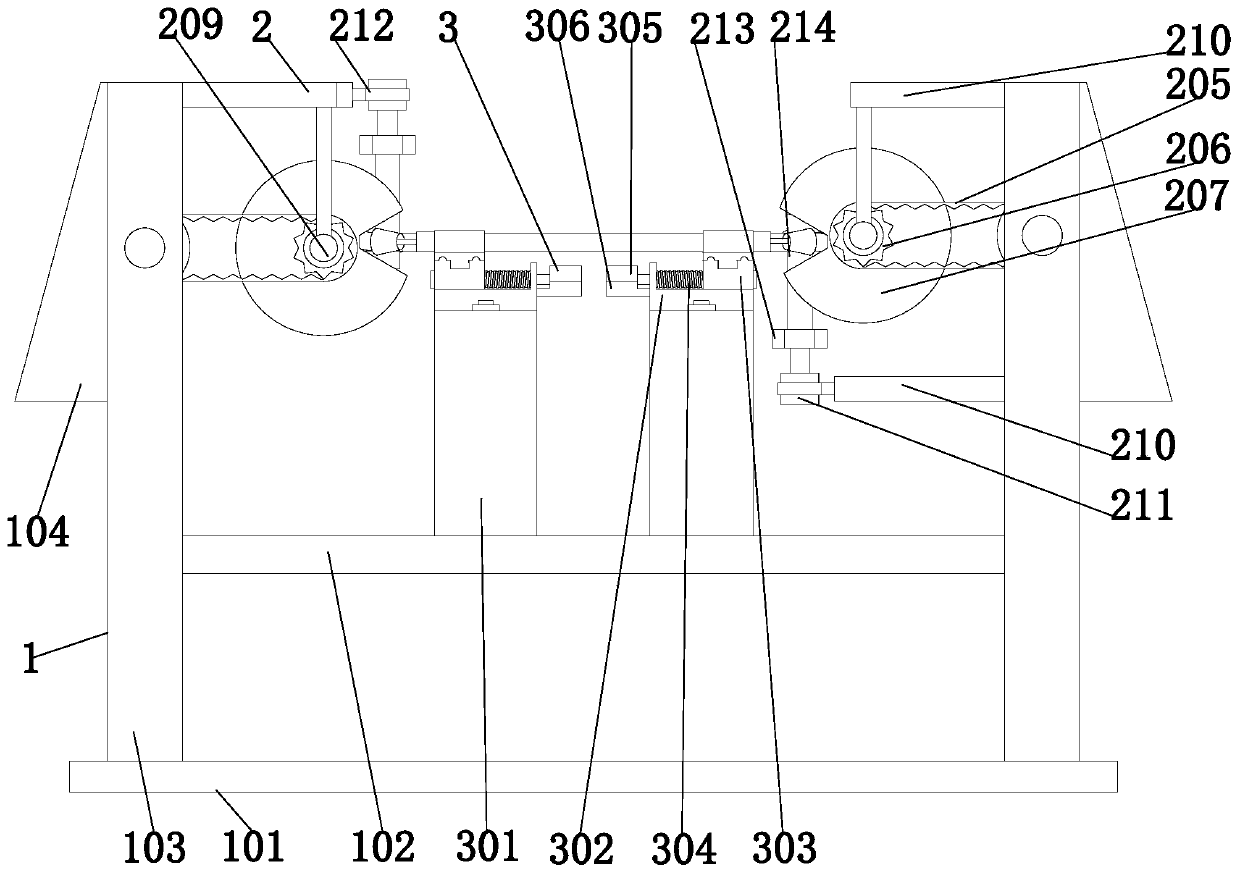

[0025] Such as Figure 1 to Figure 4 As shown, a forming auxiliary machine for making wire rods for power accessories and equipment includes a supporting mechanism 1, an actuator 2 and a welding mechanism 3. The supporting mechanism 1 is uniformly provided with an actuator 2, and the welding mechanism 3 is symmetrical Is installed on the supporting mechanism 1, and the welding mechanism 3 is located between the two sets of actuators 2; among them:

[0026] The supporting mechanism 1 includes a bottom plate 101, a transverse bracket 102, a column bracket 103, and a protective plate 104; a column bracket 103 is symmetrically installed on the bottom plate 101, and a protective plate 104 is installed on the outer wall of the column bracket 103, The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap