Intelligent conveying robot for building materials

A technology for intelligent handling and building materials, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of building materials occupying a large space, economic losses, time-consuming and labor-intensive, etc., and achieve the effect of good buffering and anti-seismic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

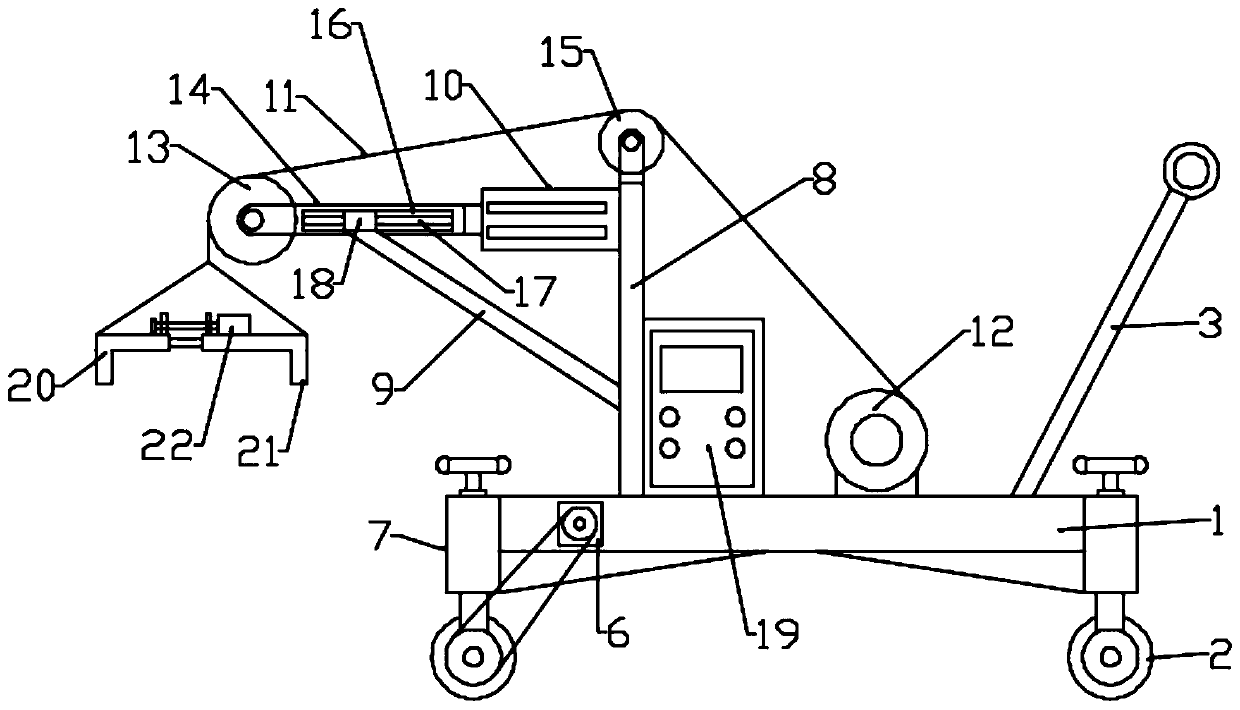

[0029] like figure 1 As shown, in the embodiment provided by the present invention, an intelligent handling robot for building materials includes a vehicle frame 1 on which a support pole 8 is fixedly installed, and one side of the support pole 8 is fixedly installed There is a horizontal telescopic rod 10, the telescopic end support frame of the horizontal telescopic rod 10 is provided with a lateral support chamber 16, the end turret of the lateral support chamber 16 is provided with a support pulley 13, and the vehicle frame 1 is also provided with a winch A motor 12, the hoisting motor 12 is wound with a steel wire rope 11, and the other end of the steel wire rope 11 is supported and erected on the support pulley 13 and then connected to the clamping mechanism;

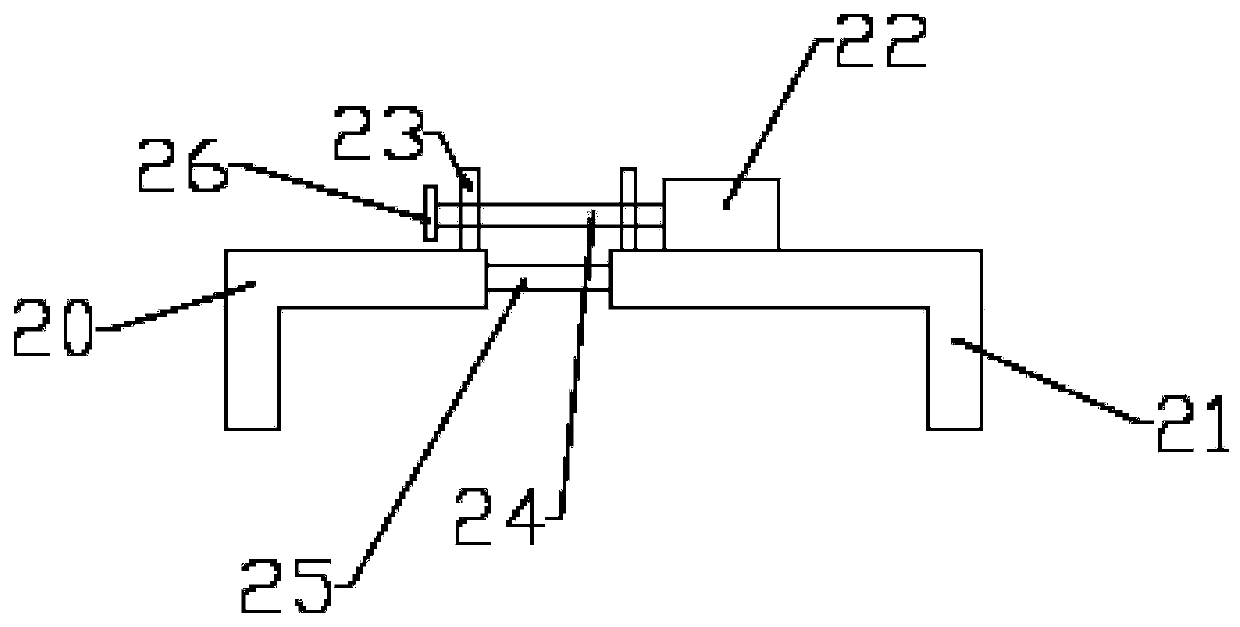

[0030] Specifically, such as figure 1 and image 3 As shown, in the embodiment provided by the present invention, the clamping mechanism includes a first clamping plate 20 and a second clamping plate 21 whose po...

Embodiment 2

[0039] like Figure 1-4 As shown, the difference from Embodiment 1 is that in the embodiment provided by the present invention, the top right end of the frame 1 is provided with a hand push rod 3;

[0040] The end portion of the vehicle frame 1 is fixedly provided with a shock-absorbing support leg 7, and the bottom end of the shock-absorbing support leg 7 is provided with a walking wheel 2, and a walking wheel for driving one of the walking wheels 2 to rotate is also installed on the vehicle frame 1. The motor 6 facilitates the movement of the whole device through the set walking wheels 2, which saves time and effort, and is convenient and fast.

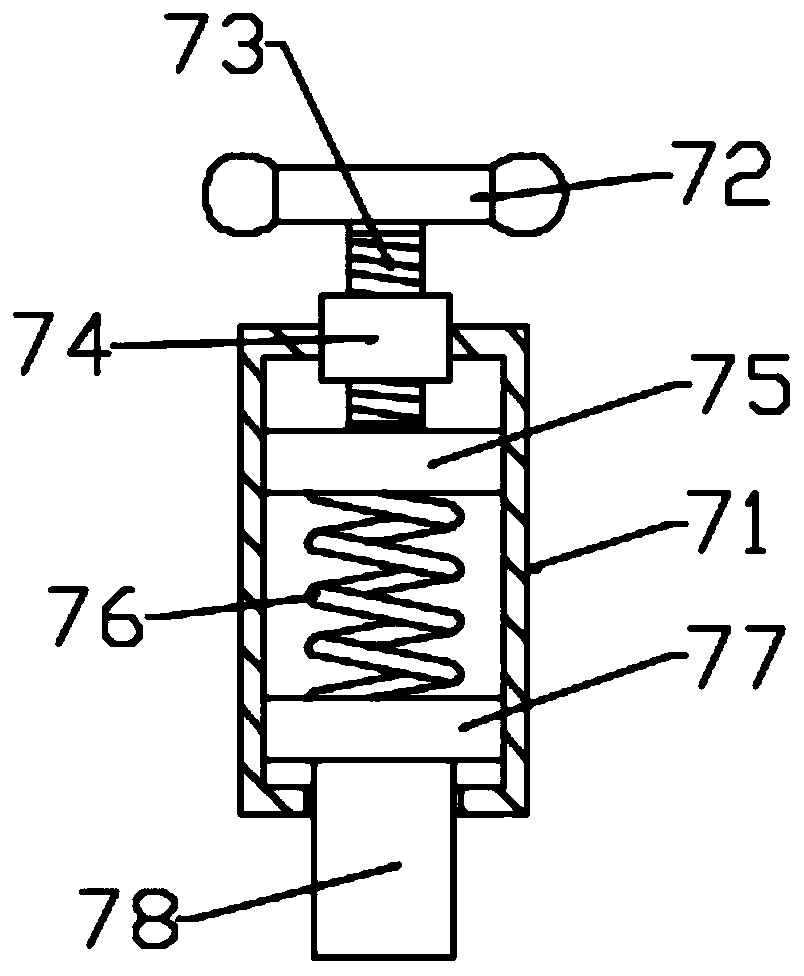

[0041]The shock-absorbing support leg 7 includes a support sleeve 71, a screw rod 73, an upper slider 75, a buffer spring 76, a lower slider 77 and a support rod 78, and the upper slider 75 and the lower slider 77 are all slid up and down on the support sleeve. In the inner cavity of the barrel 71, the buffer spring 76 is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com