Road leveling and film laying equipment

A technology for paving and paving roads, applied in the field of road leveling and film paving equipment, which can solve problems such as secondary rework, low construction efficiency, and affecting road construction progress, and achieve the effect of improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

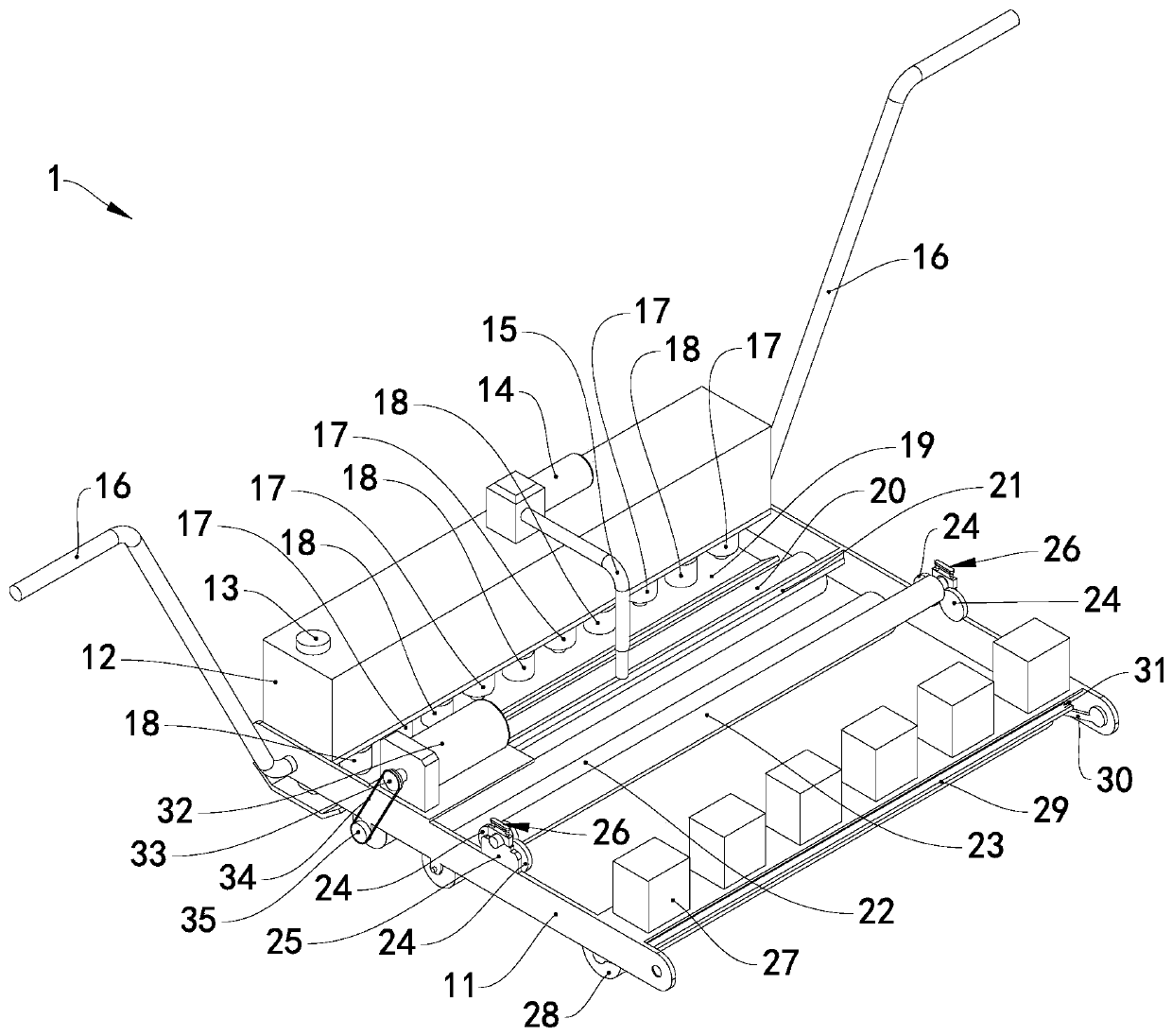

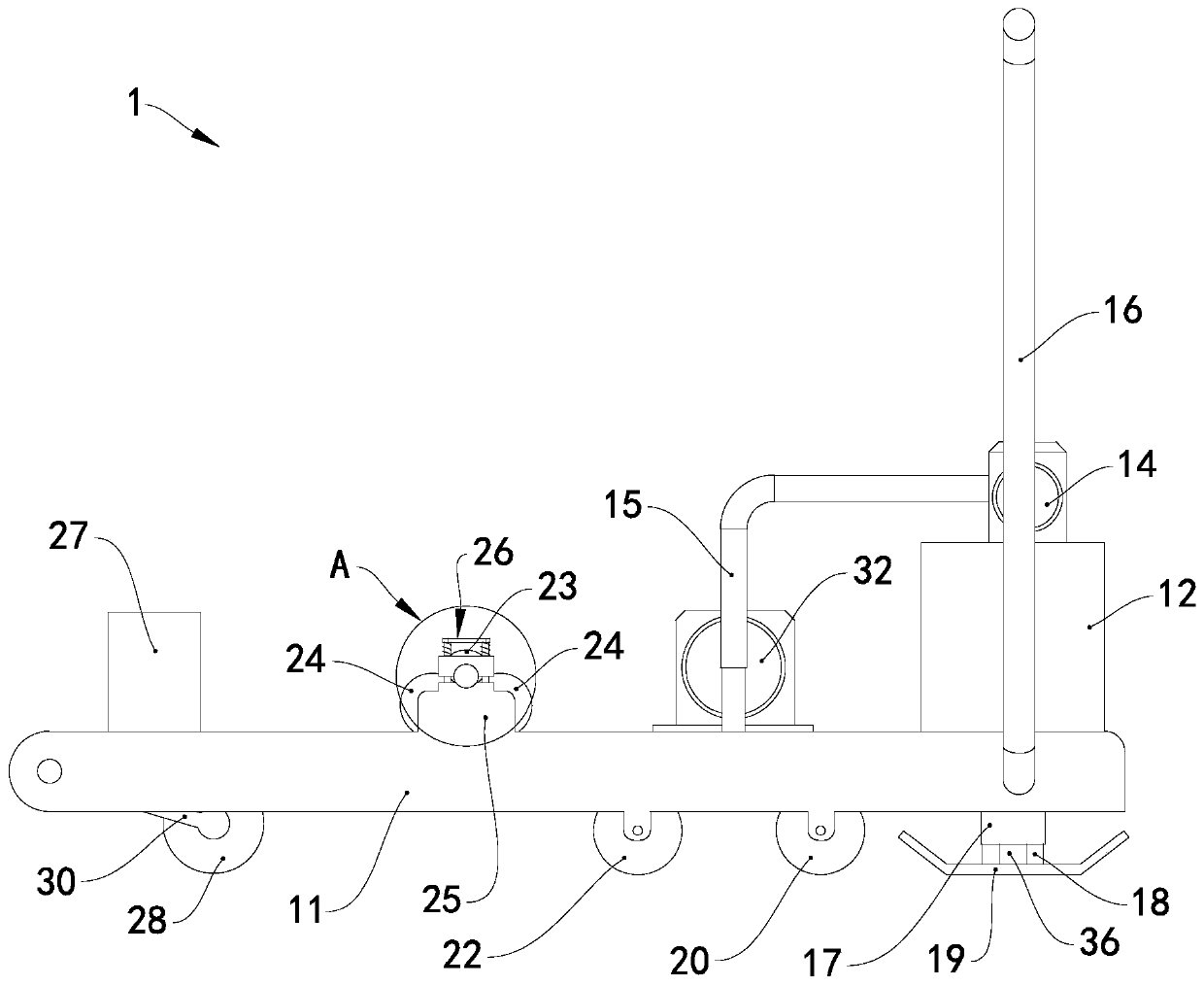

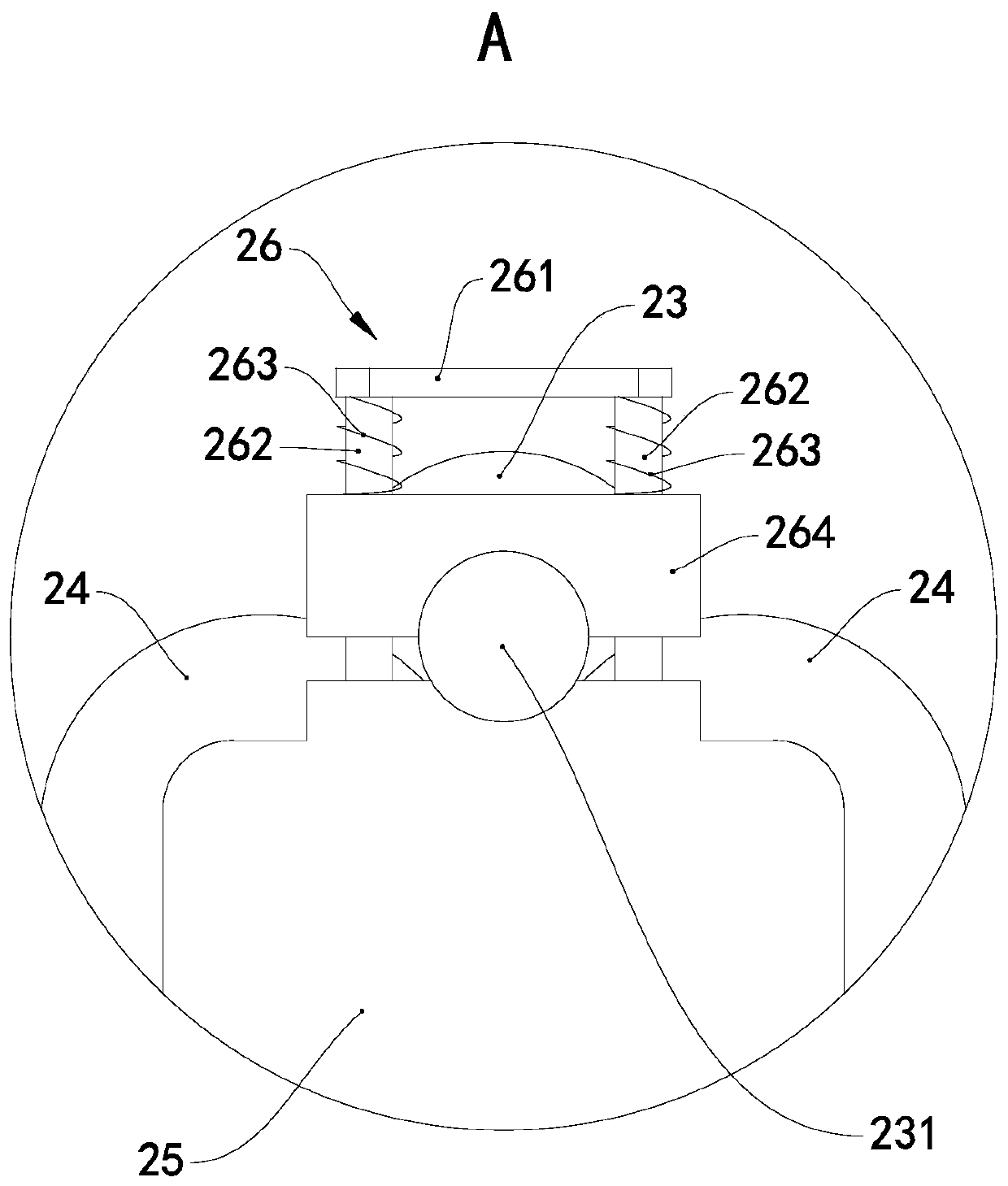

[0026] see figure 1 with figure 2 , a road leveling and paving film equipment 1 includes a frame 11, a water storage tank 12, a water pump 14, a driving device, a driving drum 20, a film roll 23, a vibrating plate 19, a flattening drum 22, a laminating drum 28, a sprinkler Rod 21, storage battery pack 27 and two handles 16, vibrating plate 19 and frame 11 are connected with a plurality of damping assemblies in vertical direction, and shock absorbing assembly forces vibrating plate 19 away from frame 11, and vibrating plate 19 is provided with A plurality of vibration motors 18. Wherein, the vibrating plate 19 extends along the axial direction of the driving drum 20 , and in the extending direction of the vibrating plate 19 , a plurality of damping assemblies and a plurality of vibrating motors 18 are alternately arranged.

[0027] The driving roller 20, the flattening roller 22 and the laminating roller 28 are respectively rotatably connected to the frame 11, the driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com