Drilling rod, drilling tool and pile machine

A technology for drill pipes and drilling tools, which is applied in the field of drilling tools, pile drivers, and drill pipes. It can solve problems such as low work efficiency, cumbersome operation process, and complex keyway shape, and achieve the effect of improving work efficiency and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

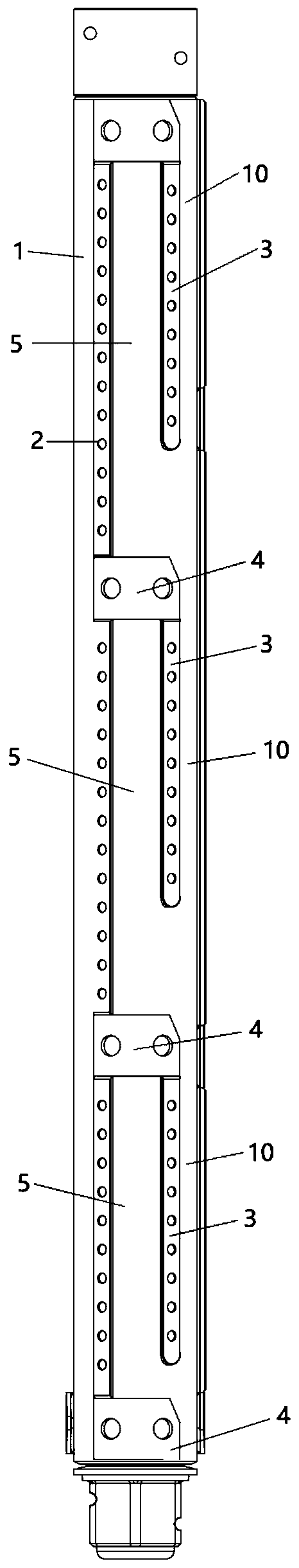

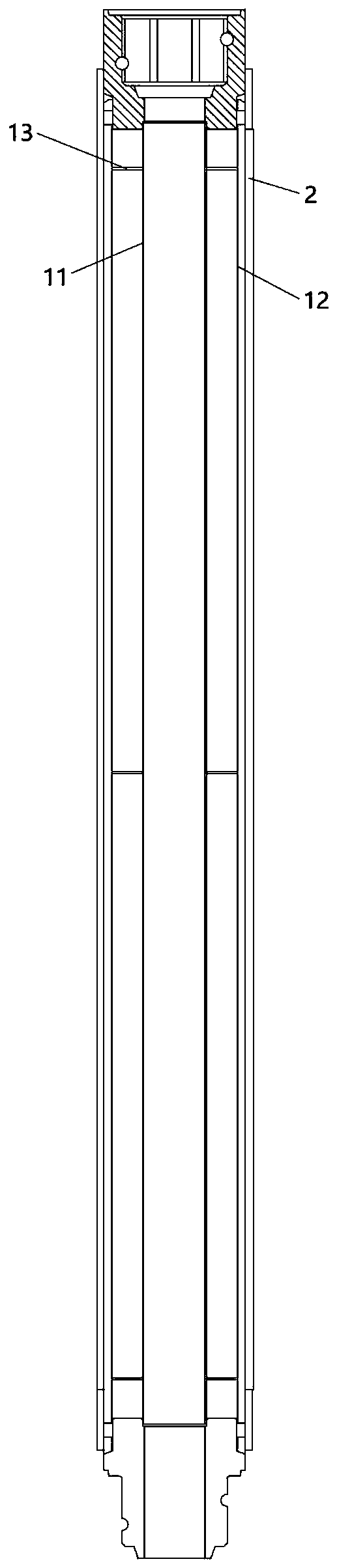

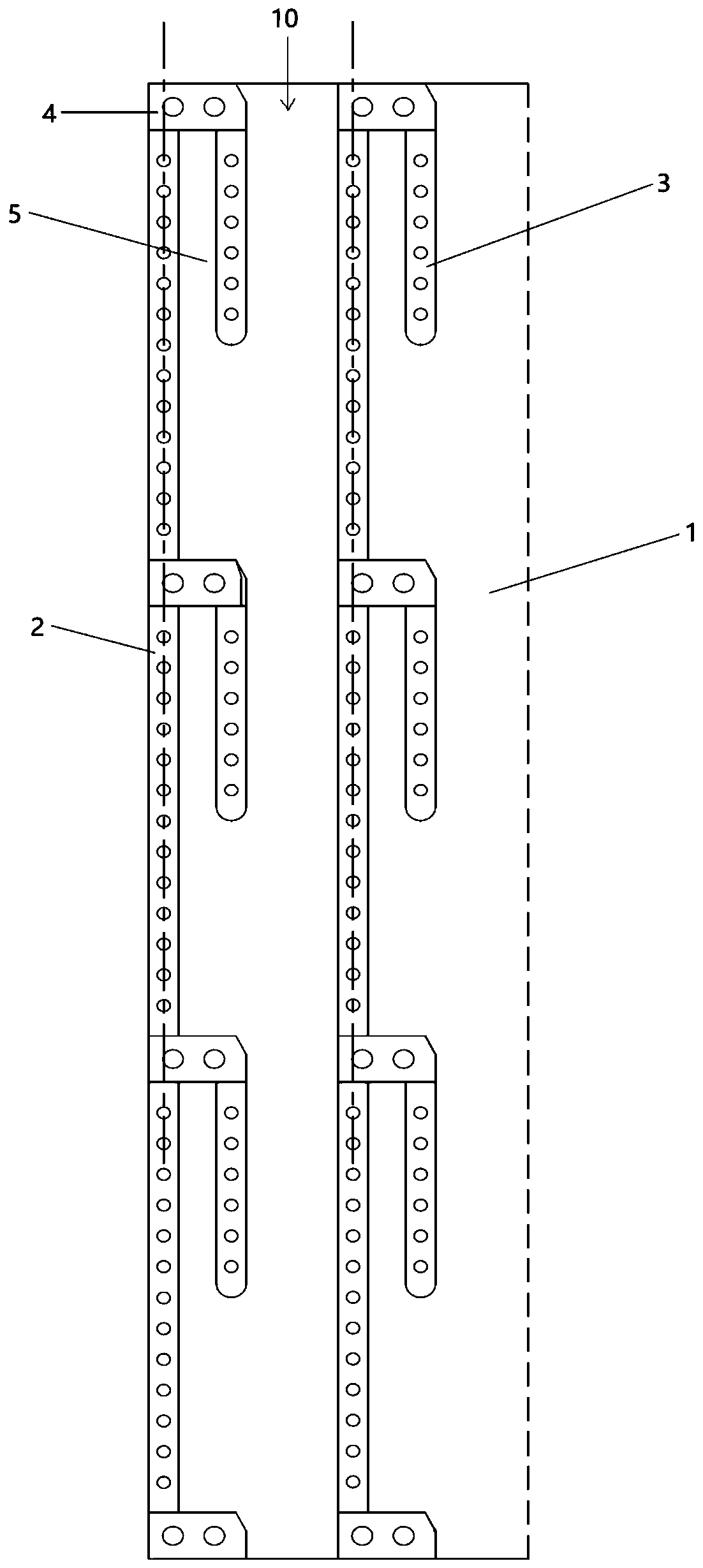

[0037] Such as Figure 1-Figure 4 As shown, the drill pipe provided in this embodiment includes a hollow driven rod 1, and the driven rod 1 is provided with a limit key group. The limit key group includes an inline first limit key 2, a plurality of inline first limit keys Two limit keys 3 and a plurality of stoppers 4. The first limit key 2 is arranged on the driven rod 1 along the axial direction of the driven rod 1, and a plurality of second limit keys 3 are arranged on the driven rod 1 at intervals along the axial direction of the driven rod 1 and are located on the first The same side as limit key 2. The distance between two adjacent second limit keys 3 is not less than the length of the convex key 60 on the inner wall of the power tube 6 in the drill bit.

[0038]A stopper 4 is connected between each second limit key 3 and the first limit key 2, and the stopper 4 is used to form a The limit groove 5 is used to accommodate the convex key 60 on the inner wall of the powe...

Embodiment 2

[0065] The drilling tool provided in this embodiment includes the power head and the drill rod in the first embodiment. The power head includes a power tube. The inner wall of the power tube is provided with a bar-shaped convex key. The power tube is sleeved on the driven rod in the drill pipe. The convex key on the inner wall of the power tube can pass through two adjacent After the interval between the second limiting grooves is located in the limiting grooves.

[0066] Wherein, the power tube is used to drive the driven rod to rotate by its own rotation.

[0067] Further, grooves may be provided on the inner wall of the power tube, and the strip-shaped convex keys may be embedded in the grooves and fixed in the grooves by screws.

[0068] Further, a protrusion can be provided in the groove bottom of the groove on the inner wall of the power tube, and a dovetail groove corresponding to the above protrusion can be provided at the position of the bar-shaped protrusion key cor...

Embodiment 3

[0072] The pile driver provided in the present embodiment includes the drilling tool in the second embodiment, and the pile driver provided in the present embodiment can solve the same technical problem as the drilling tool in the second embodiment and achieve the same technical effect.

[0073] Therefore, the pile driver provided by this embodiment also alleviates the process of adjusting the position of the drive tube on the drill rod in the existing drilling tool in the prior art, and when the drive tube is moved for a long distance, due to the stepped The shape of the keyway formed between the bar splines is complex, so it is necessary to lift the drive tube on the drill pipe multiple times and make the drive tube rotate after lifting the drive tube. The operation process is cumbersome, resulting in low work efficiency. technical problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com