A device and method for automatic detection of plane residual stress based on magnetoelastic effect

An automatic detection device, residual stress technology, applied in measuring devices, force/torque/work measuring instruments, force measurement by measuring the change of magnetic properties of materials caused by applied stress, etc., can solve complex motion control, automatic manipulator price Expensive and other problems, to achieve the effect of easy overall structure, small footprint, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

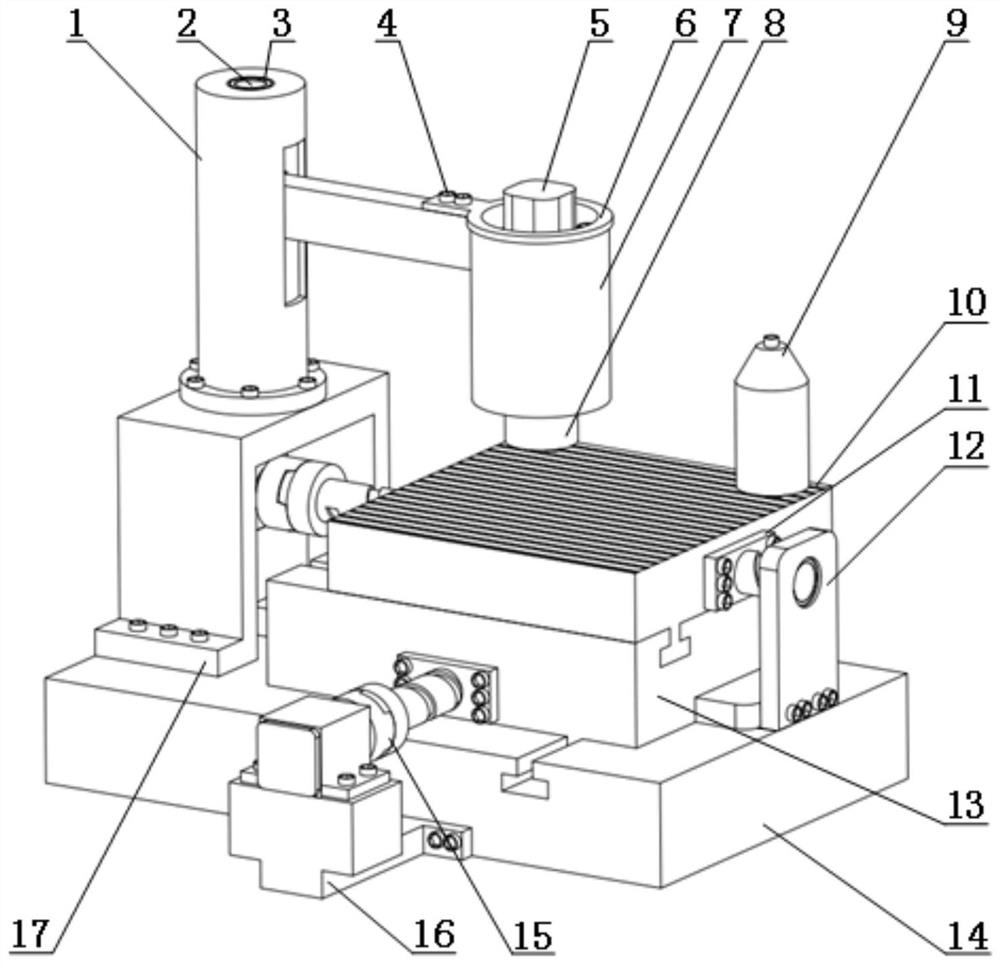

[0043] Attached below Figure 1-Figure 7 The present invention is described in detail, specifically, the structure is as follows:

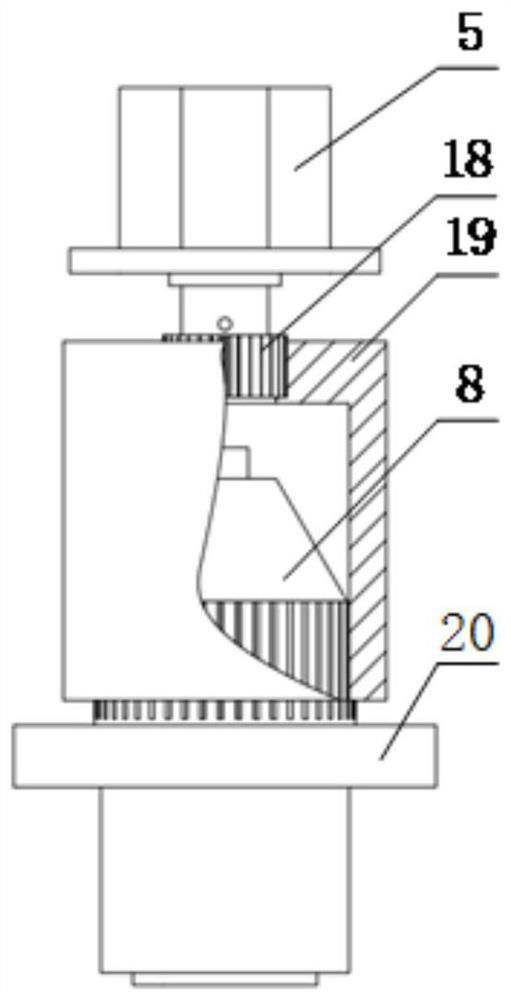

[0044] This embodiment provides an automatic detection device for plane residual stress based on the magnetoelastic effect, including a detection probe 8, a compensation probe 9, a lifting device, a workbench and a driving mechanism thereof, wherein the detection probe 8 and the compensation probe 9 are of the same specification , Probes with the same internal structure that can detect changes in magnetic properties. The lifting device is connected with the detection probe 8, and the compensation probe 9 is placed on the workbench.

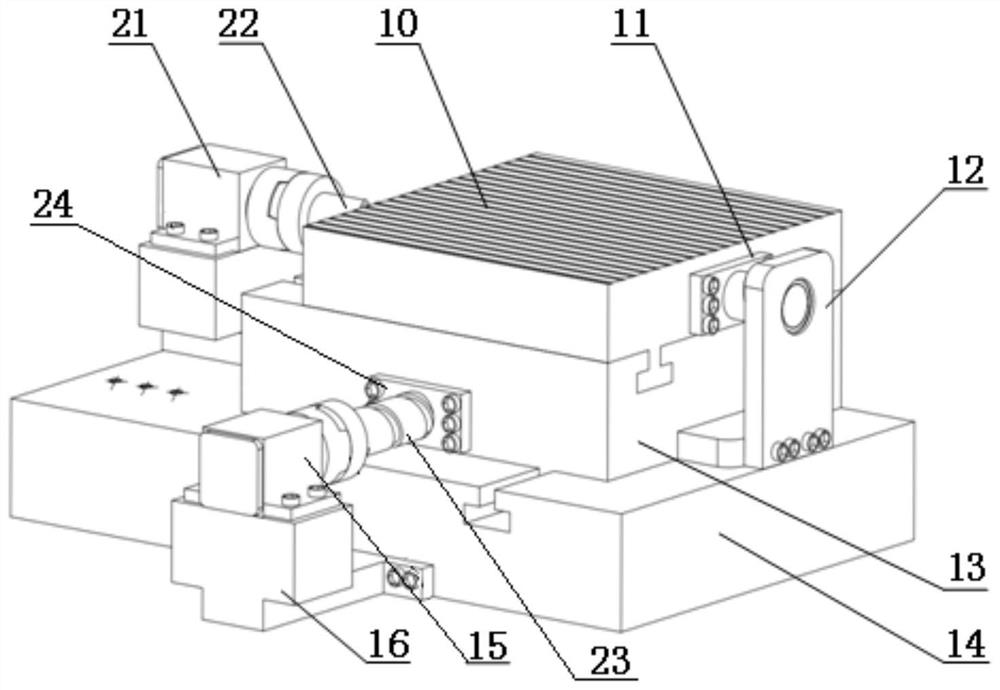

[0045]The workbench is provided with three, i.e. the first workbench 10, the second workbench 13, the third workbench 14, and the first workbench 10 is located on the second workbench 13 and is slidably connected with it, the third workbench 14 It is arranged under the second workbench 13 and is slidably connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com