Polymerizable compound, liquid crystal composition using same, and liquid crystal display element

A liquid crystal composition and compound technology, which is applied in the directions of liquid crystal materials, chemical instruments and methods, nonlinear optics, etc., can solve the problem of uneven orientation of the peripheral part of the panel, and achieve the effect of high compatibility and excellent vertical orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0842] (Example 1) Preparation of liquid crystal composition

[0843] When the composition constituted according to the compounds and mixing ratios shown in the following Table 3 was set to 100 parts by mass, 0.3 parts by mass of the following polymerizable compound (R-1-0) was added, heated and melted, and the resulting combination The material was set as LC-1.

[0844] [table 3]

[0845]

[0846] [chem 139]

[0847]

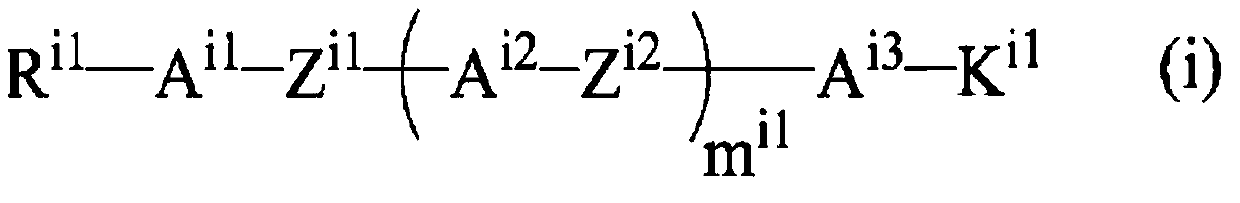

[0848] Furthermore, 0.5 mass parts of compound (P-J-1) corresponding to compound (i) was added with respect to 100 mass parts of LC-1, and it melt|dissolved by heating, and prepared the liquid crystal composition.

[0849] [chem 140]

[0850]

Embodiment 2~24

[0852] In the addition amount shown in Table 4, the following compound was added to LC-1 instead of the compound (P-J-1) in the addition amount of 0.5 parts by mass in Example 1, except that it was performed in the same manner as in Example 1, Prepare liquid crystal composition.

[0853] [chem 141]

[0854]

[0855] [chem 142]

[0856]

[0857] [Table 4]

[0858]

[0859] [table 5]

[0860]

Embodiment 25~54

[0862] Instead of the liquid crystal composition HLC-1 in Example 1, a composition composed of the compounds and mixing ratios shown in Table 6 below was prepared in the same manner as in Example 1, and the prepared liquid crystal composition was HLC-1. 2 to HLC-8.

[0863] [Table 6]

[0864]

[0865] Furthermore, for the base composition which added 0.3 mass parts of polymerizable compounds (R-1-0) when HLC-2 to HLC-8 were respectively made into 100 mass parts, it prepared by heat-melting, and was respectively set as LC-2 to LC-8.

[0866] In addition, the base composition obtained by adding 0.3 parts by mass of the following polymerizable compound (R-1-1) to each of HLC-1 to HLC-8 as 100 parts by mass was prepared by heating and melting. LC-9 to LC-16.

[0867] [chem 143]

[0868]

[0869] In each example, the additive compound shown in Table 7 was added in the amount shown in Table 7 instead of 0.5 parts by mass of (P-J-1) in Example 1, and LC-2 shown in Table 7 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com