Lateral packing type downward penetrating binding machine

A strapping machine and side-playing technology, which is applied to the parts of strapping machines, strapping materials, paper/cardboard containers, etc., can solve the problems of poor adaptability of fully automatic strapping machines and cannot meet the actual use needs, and meet the strapping requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

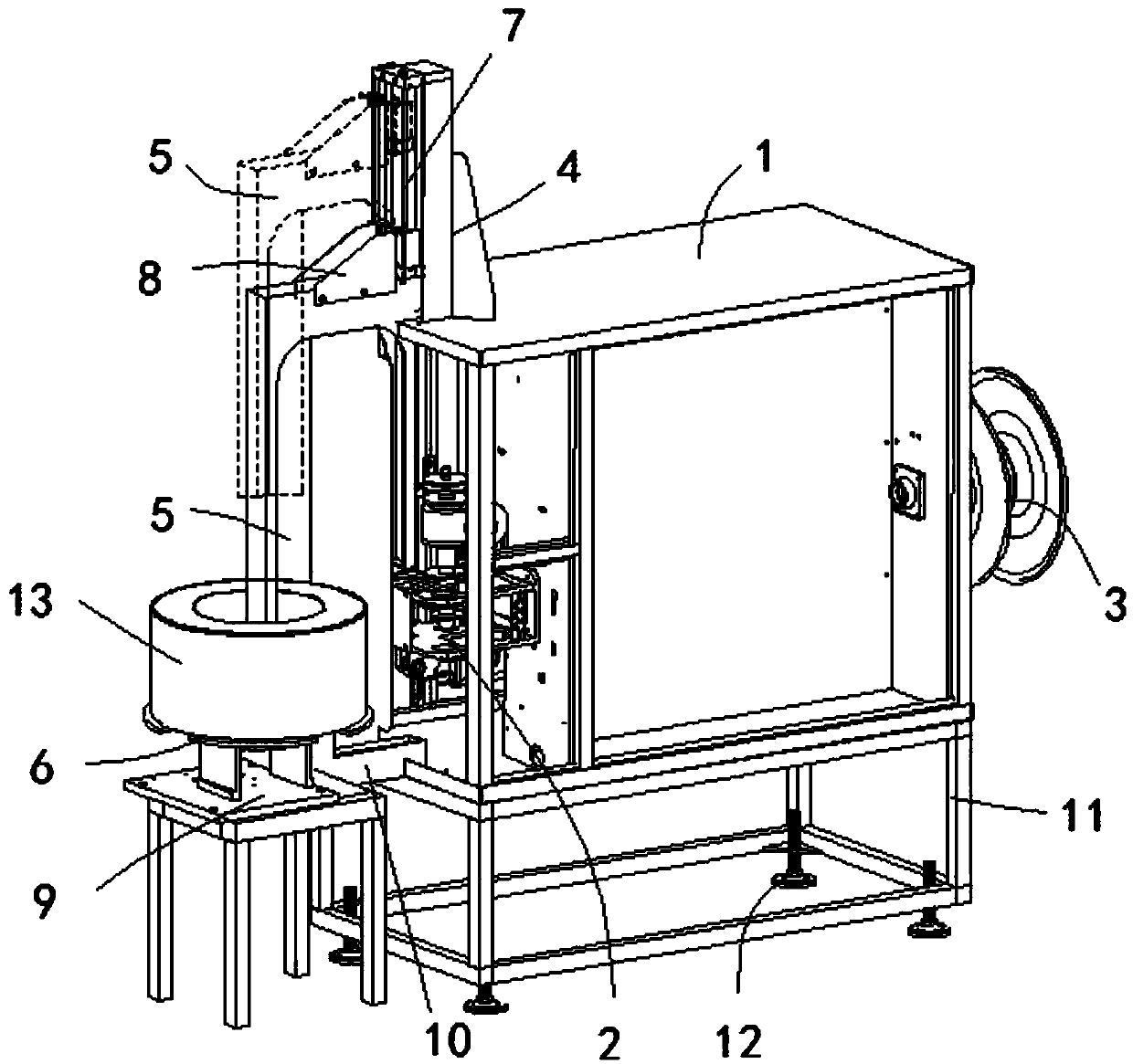

[0030] A kind of side beating type lower piercing sword strapping machine of the present embodiment, refer to figure 1 : Including a strapping body, the strapping body includes a casing 1, a core 2, a storage unit 3 and an electric control unit, the core 2 and the storage unit 3 are respectively fixed on the left and right side walls of the casing 1, and the front of the casing 1 The side top is fixedly connected with a fixed frame 4, and the fixed frame 4 is provided with a bow frame 5 that can move up and down, and the lower end of the bow frame 5 is provided with an opening; the front of the movement 2 is fixed with a placement platform 6, and the height of the placement platform 6 is adjustable , and a through hole is formed at the center thereof, and the outer lower end of the bow frame 5 can go down into the through hole.

[0031] Wherein, the bow frame 5 and the front side wall of the fixed frame 4 are connected together through a direct motion structure, and the bow fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap