Hybrid full-automatic high-speed strapping machine

A strapping machine, fully automatic technology, applied to the parts of strapping machinery, strapping objects, strapping materials, etc., can solve the problems that cannot meet the requirements of high speed, heavy objects cannot be tied tightly, and the response speed cannot be achieved. Response speed Fast, shortens the belt feeding time, and has the effect of strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

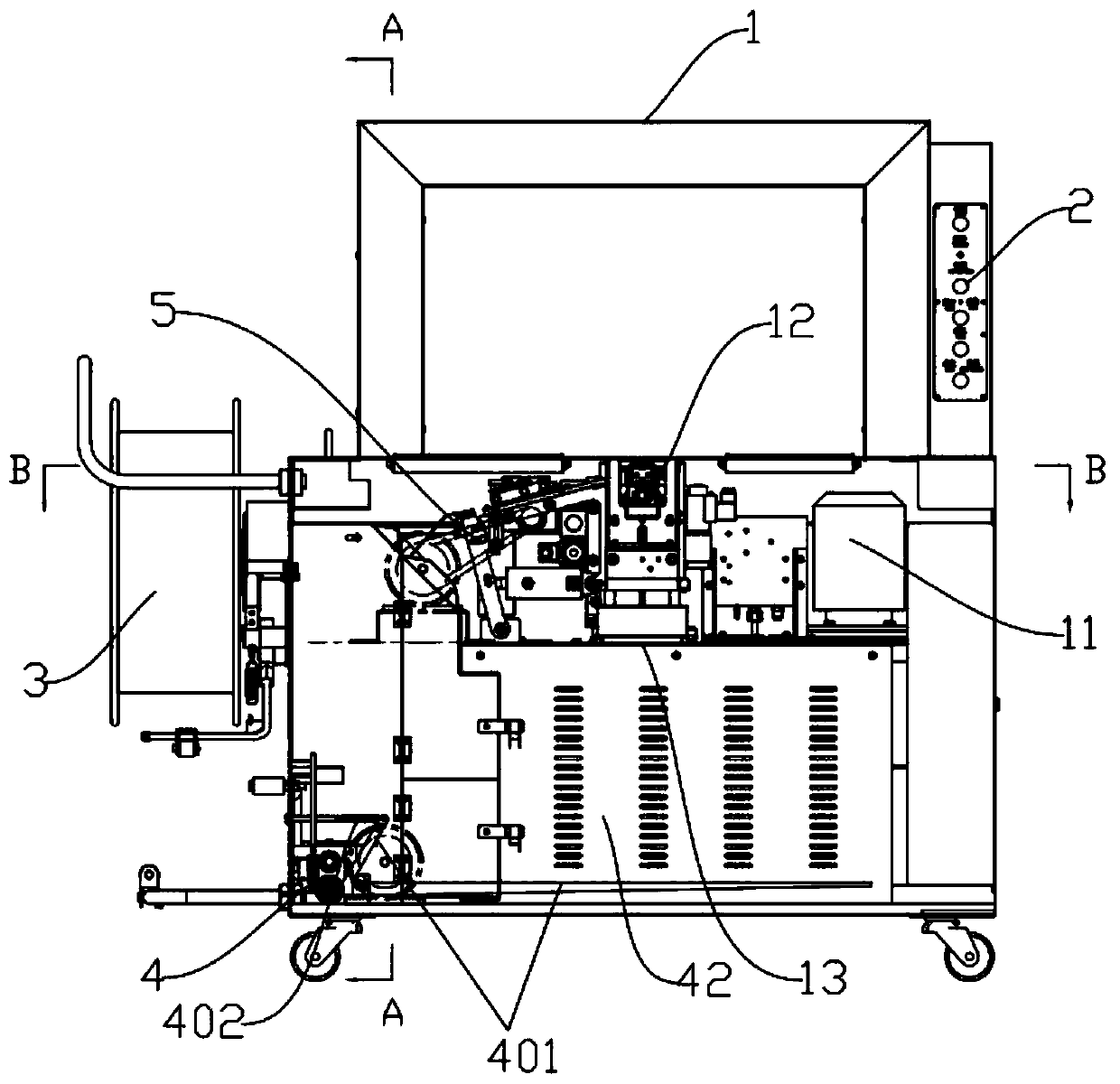

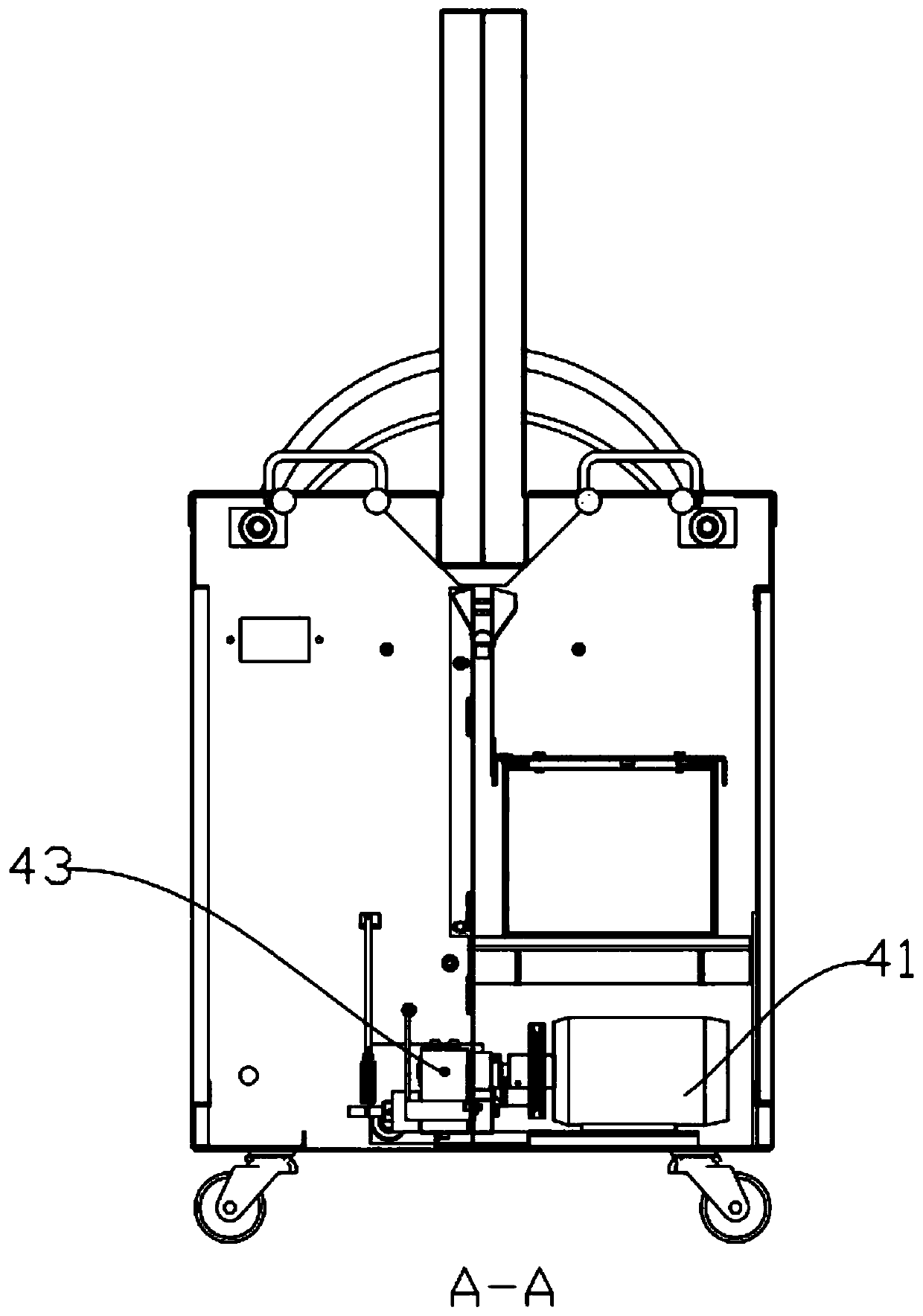

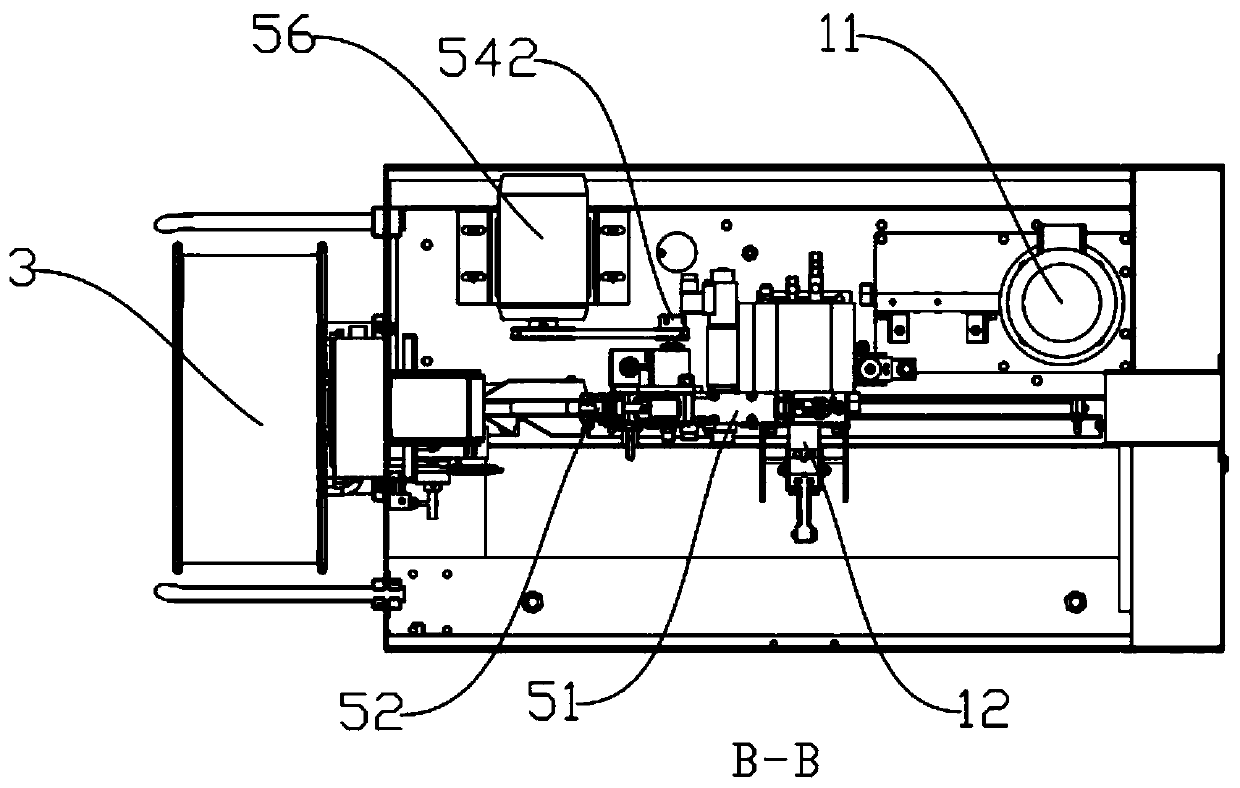

[0041] refer to Figure 1-9 , a hybrid full-automatic high-speed strapping machine, including a strapping machine body 1 and a controller 2 electrically connected; The tape reel 3, the upper cover 13 is arranged between the oil supply mechanism 11 and the hydraulic cutting mechanism 12, and also includes:

[0042] The pre-feeding mechanism 4 includes a pre-feeding motor 41 for conveying the strapping, a storage box 42 for storing the strapping, and a pre-feeding controller 43 electrically connected to the pre-feeding motor 41;

[0043] The feeding and unwinding mechanism 5 includes a belt-entry track body 51 fixedly connected with the hydraulic pressure cutting mechanism 12, and a manipulator 52 for tightening the strapping belt; A feed wheel 54 corresponding to the pinch wheel 53 is provided; the manipulator 52 is rotatably connected to a hydraulic cylinder 55 arranged on the entry track body 51, and the upper cover 13 is also provided with a Send the reversing motor 56 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com