Sorting conveyor

A conveyor and a part of the technology, applied in the field of conveyors, can solve the problems that item sorting cannot be accurate, fast, manual sorting consumes too many people, and the efficiency is low, so as to expand the logistics transportation path and transportation volume, improve Work efficiency, avoid the effect of unbalanced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

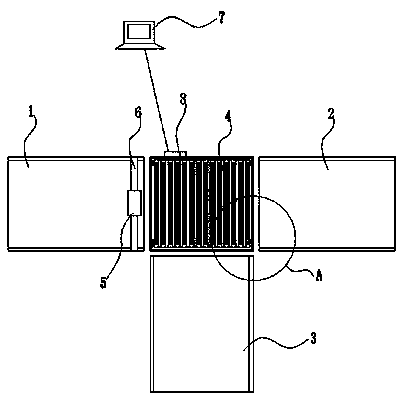

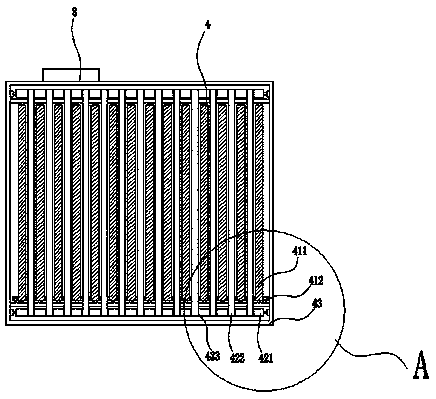

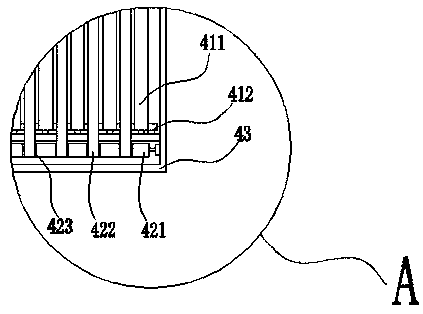

[0031] Such as figure 1 As shown, a sorting conveyor includes a first conveyor belt 1, a second conveyor belt 2, a third conveyor belt 3 and a redirection device 4, and also includes a visual collection device 5, the first conveyor belt 1 and the second conveyor belt The conveying directions of the two conveyor belts 2 are consistent, and a redirection device 4 is arranged between the end of the first conveyor belt 1 and the starting point of the second conveyor belt 2, and the visual collection device 5 is fixedly arranged between the first conveyor belt 1 and the starting point of the second conveyor belt 2. Above the junction of the diverting device 4 and fixed by a support frame 6, the diverting device 4 is also connected with a third conveyor belt 3, and the third conveyor belt 3 is connected to the first conveyor belt 1 and the second conveyor belt 2 The conveying direction is perpendicular to.

[0032] In the above embodiment, the articles are transported by the first ...

Embodiment 2

[0039] Such as figure 1 As shown, a sorting conveyor includes a first conveyor belt 1, a second conveyor belt 2, a third conveyor belt 3 and a redirection device 4, and also includes a visual collection device 5, the first conveyor belt 1 and the second conveyor belt The conveying directions of the two conveyor belts 2 are consistent, and a redirection device 4 is arranged between the end of the first conveyor belt 1 and the starting point of the second conveyor belt 2, and the visual collection device 5 is fixedly arranged between the first conveyor belt 1 and the starting point of the second conveyor belt 2. Above the junction of the diverting device 4 and fixed by a support frame 6, the diverting device 4 is also connected with a third conveyor belt 3, and the third conveyor belt 3 is connected to the first conveyor belt 1 and the second conveyor belt 2 The conveying direction is perpendicular to.

[0040] In the above embodiment, the articles are transported by the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com