A hydraulic cylinder-driven iron driller's walking mechanism with lifting function and its adjustment method

A technology of walking mechanism and adjustment method, which is applied to drilling equipment and methods, drilling tools, earthwork drilling and mining, etc., which can solve problems such as difficult maintenance and disassembly, high cost of hydraulic motors and racks, and large space on the drill floor. The effect of reducing the overall weight, reducing the volume and weight of parts, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

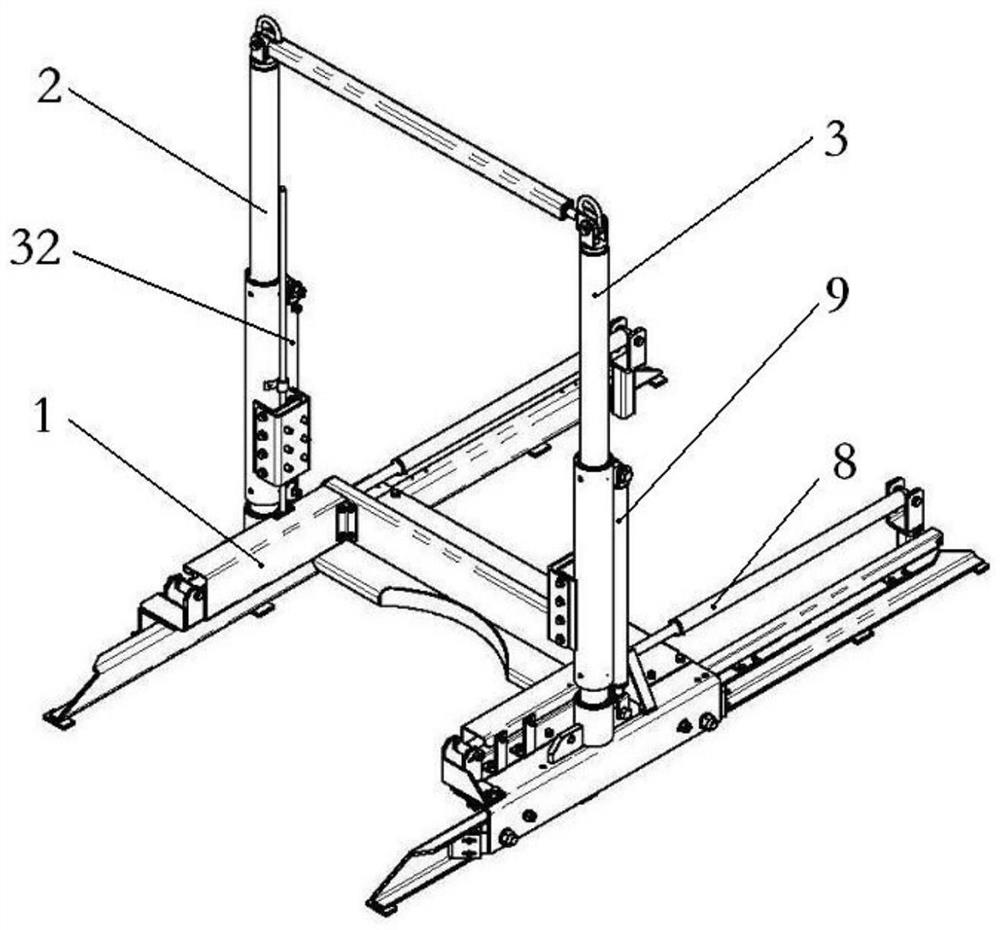

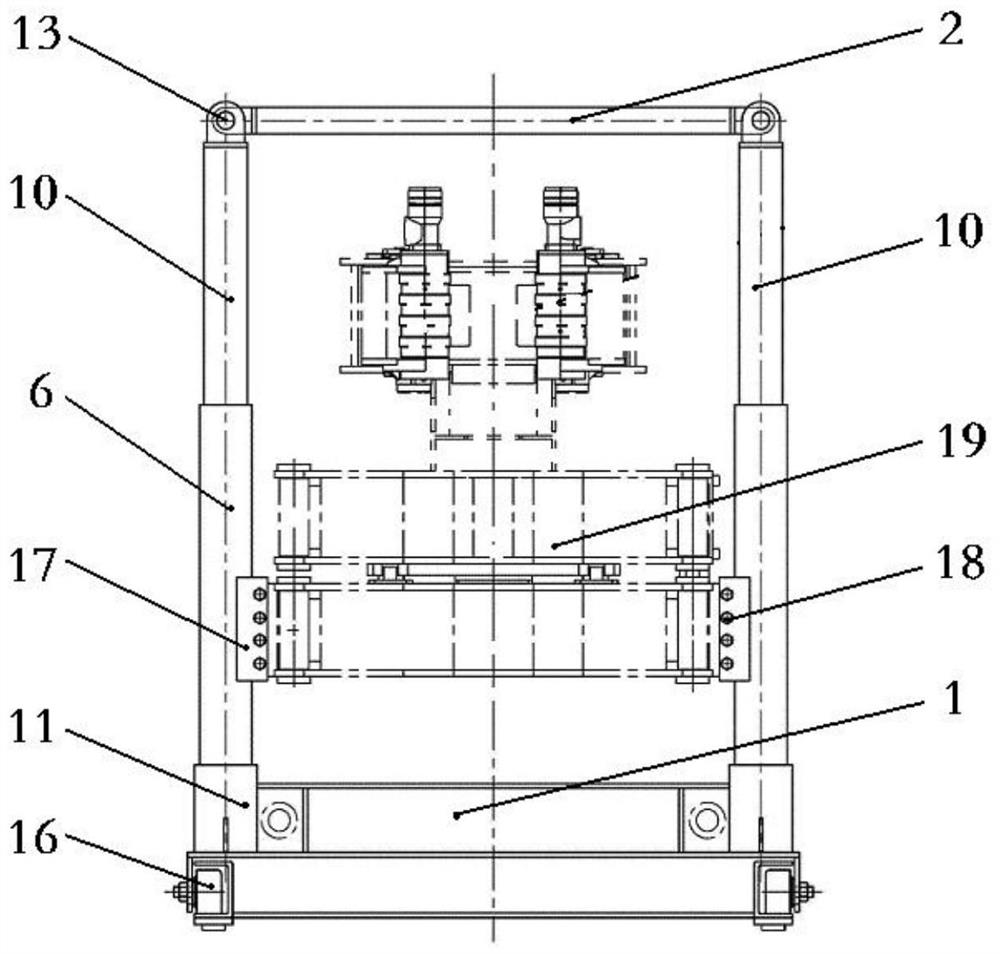

[0035] Such as Figure 1-3 As shown, a hydraulic cylinder drives an iron driller's walking mechanism with a lifting function, including a base 1 and a suspension frame 2 installed on the base 1; the base 1 includes two translation components, and the two translation components are connected by cross braces 20; The bottom of the suspension frame 2 is connected with the two translation assemblies, and the inner side of the suspension frame 2 is connected with the pincer head assembly 19 .

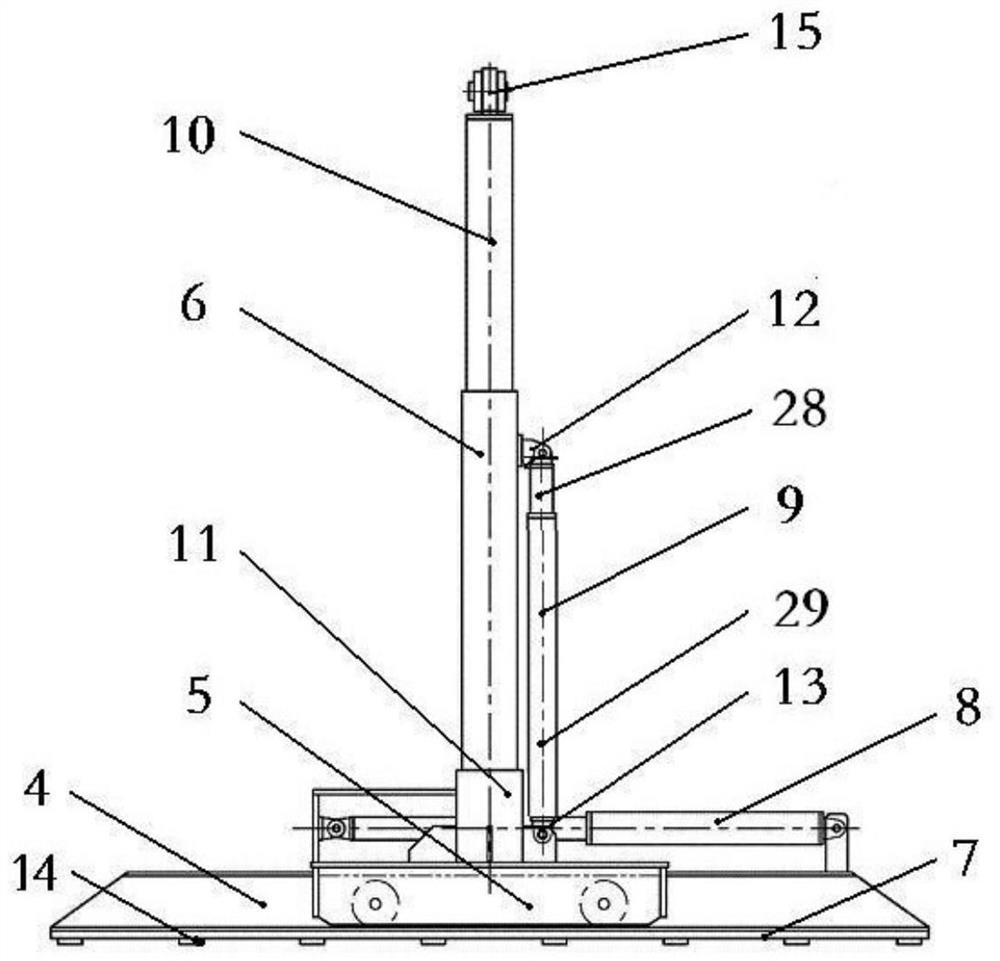

[0036] Such as Figure 4 As shown, the translation assembly includes a fixed inner slide rail 4 and an outer slide rail 5 that is slidably connected, and a translation cylinder 8 installed between the inner slide rail 4 and the outer slide rail 5, that is, the inner side is realized through the telescopic movement of the translation cylinder 8 . Relative m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com