High-temperature high-speed jet deflection device

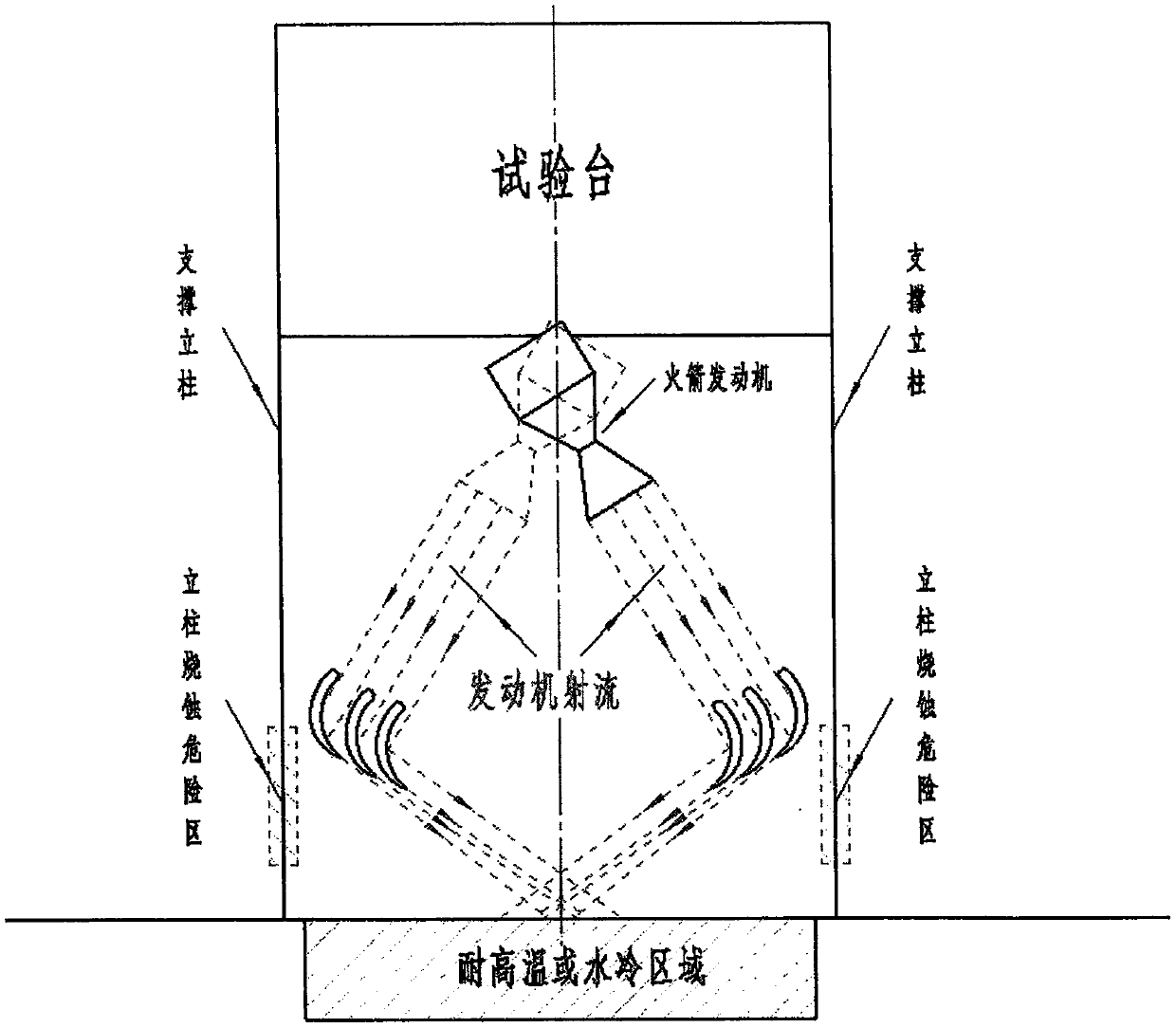

A high-speed jet and deflection device technology, which is applied to jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as large civil engineering, equipment investment burden, increased water spray area, and failure to carry out swing tests, etc., to achieve equipment investment Effects of light load, small aerodynamic loss, and low drag coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

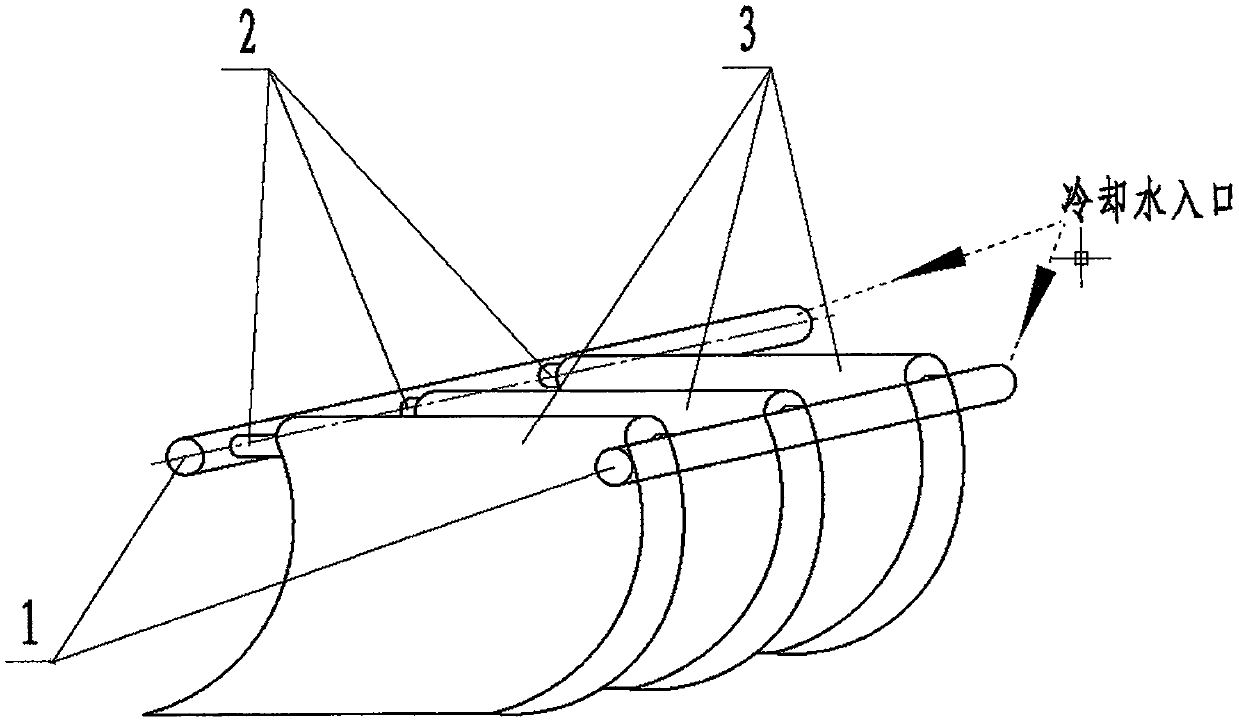

[0015] A high-temperature high-speed jet deflection device is characterized in that the device is composed of a main flow pipe 1, a branch flow pipe 2, and a guide vane array 3; the main flow pipe 1, the branch flow pipe 2, and the guide vane array 3 are all made of powder alloy and There is a flow path inside; the main flow pipe 1 is used to support the branch pipe 2 and the guide vane array 3; water.

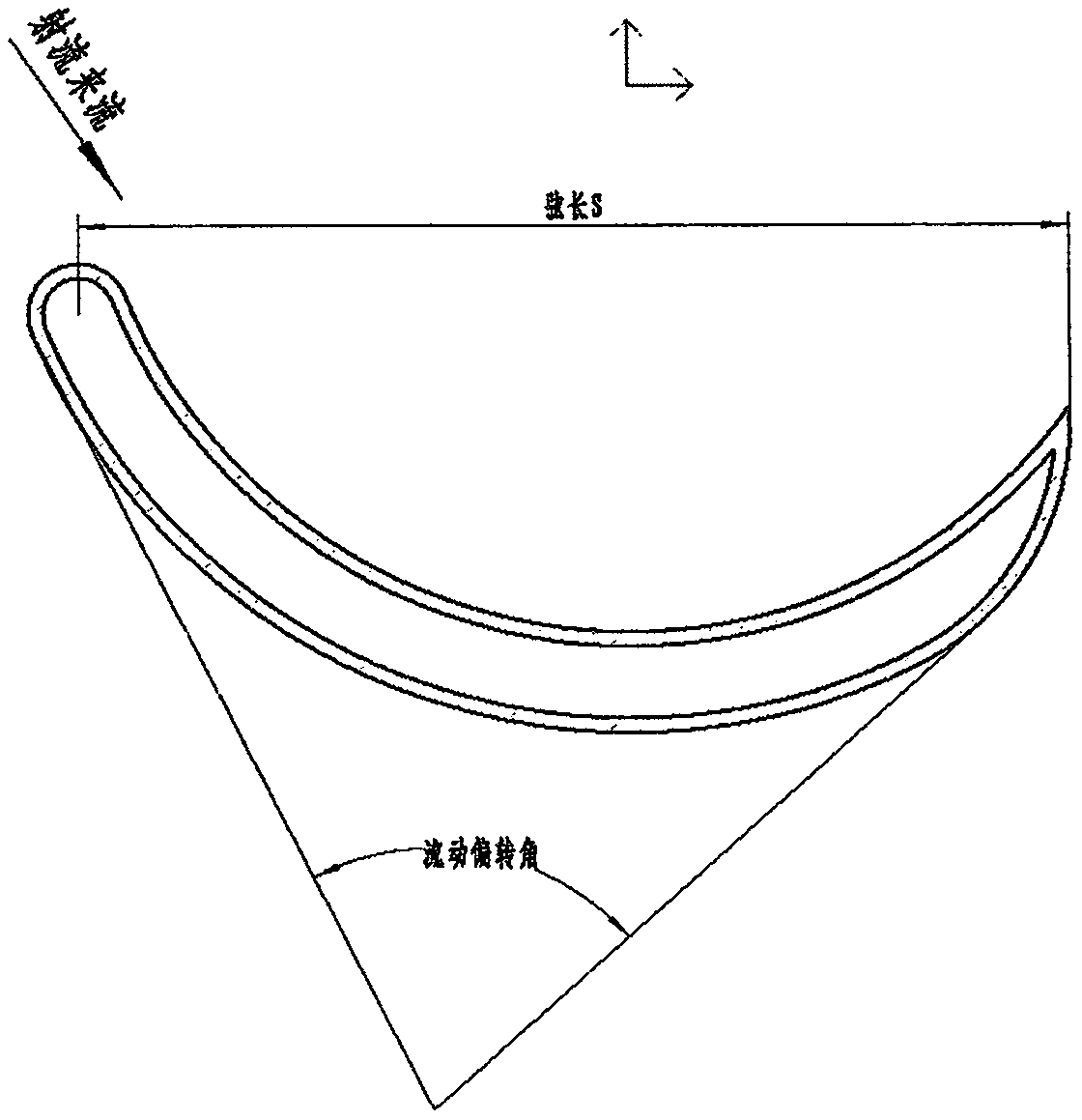

[0016] The implementation of the invention first determines the diameter D of the nozzle outlet of the engine that needs to be tested e , velocity Ue and pressure Pe, determine the aerodynamic parameters at the installation position of the jet deflection device, determine the wall thickness requirements of each guide vane in the main flow pipe 1, branch pipe 2, and blade array 3; secondly, determine the guide vane according to the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com