A pressure reducing and stabilizing valve applied to the preparation of fuel cells

A fuel cell and voltage stabilizing valve technology, which is applied in the field of pressure reducing and stabilizing valves, can solve problems such as damage to power generation modules, and achieve the effects of easy processing, reduced manufacturing costs, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

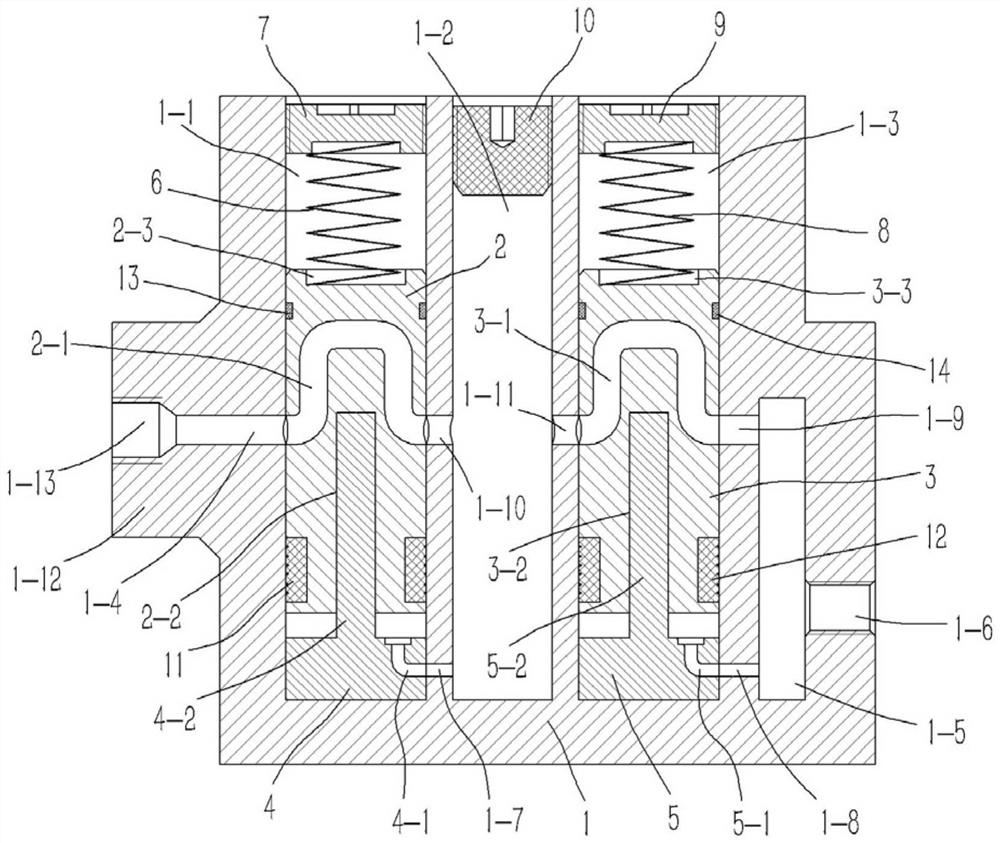

[0016] Example: see figure 1 As shown, a pressure reducing and stabilizing valve applied to the preparation of fuel cells includes a valve body 1, a cylindrical first valve core 2 and a second valve core 3, and a first valve hole 1-1 is formed on the valve body 1 And the second valve hole 1-3, between the first valve hole 1-1 and the second valve hole 1-3, the valve body 1 is formed with a pressure stabilizing groove 1-2, the first valve core 2 and the second valve core 3 are respectively plugged into the first valve hole 1-1 and the second valve hole 1-3 of the valve body 1, and the lower ends of the first valve hole 1-1 and the second valve hole 1-3 are plugged and fixed with the first The pad 4 and the second pad 5, the lower ends of the first valve core 2 and the second valve core 3 respectively press against the first pad 4 and the second pad 5, the first valve core 2 and the second valve core The upper end of 3 is respectively pressed against the first compression sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com