Enhanced boiling heat transfer surface utilizing synergistic effect of microstructure and composite wettability

A synergistic effect and enhanced boiling technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as heat transfer deterioration, achieve the effects of enhancing boiling heat transfer performance, enhancing flow field disturbance, and promoting bubble detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific working processes.

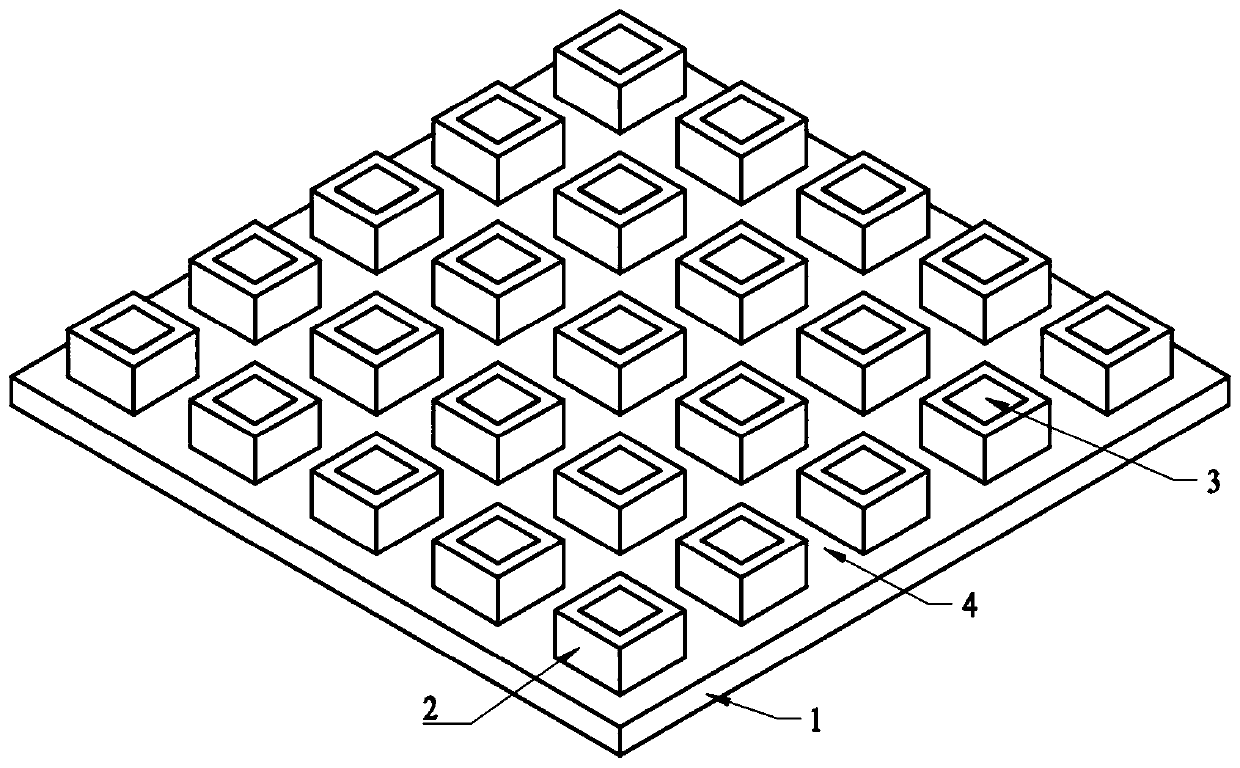

[0020] see figure 1 , the present invention includes a heating substrate 1 and a number of square pillars 2 arranged on the surface of the heating substrate 1, a number of interpenetrating channels 4 are formed between adjacent square pillars 2, and a chemical modification method is used on the top of each square pillar The surface is provided with a hydrophobic surface layer with an area smaller than that of the top of the square column, forming a partially wettability modified area 3, whose static contact angle is 94°-125°, while the rest of the surface maintains the original wettability, that is, hydrophilicity.

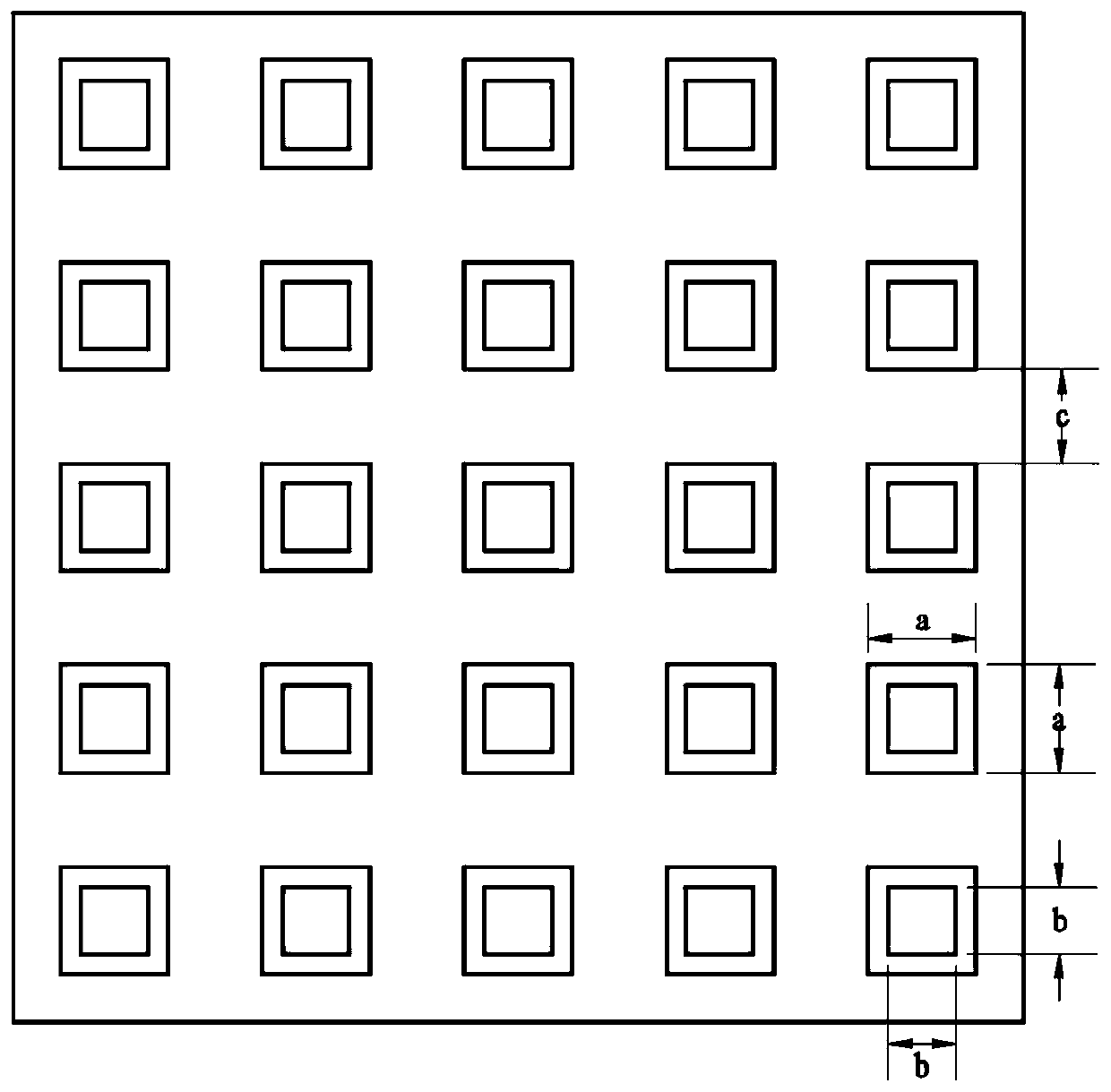

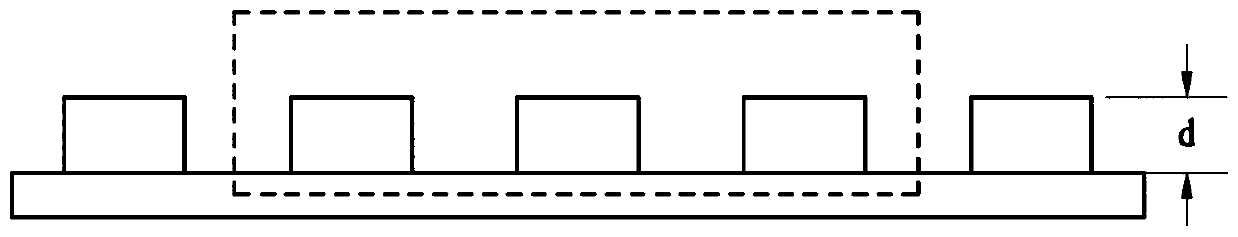

[0021] see figure 2 , image 3 , the square column 2 and the channel 4 of the present invention are processed on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com