Cold heading device and cold heading process for rivet nut forming, and rivet nut

A blind rivet nut and cold heading technology, which is applied in the field of fastener manufacturing, can solve the problems that the sealing performance and torque resistance performance of the blind rivet nut cannot be guaranteed, the sealing effect cannot meet the use requirements, and the torque attenuation of the blind rivet nut is achieved. The effect of small torque attenuation, guaranteed sealing performance and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

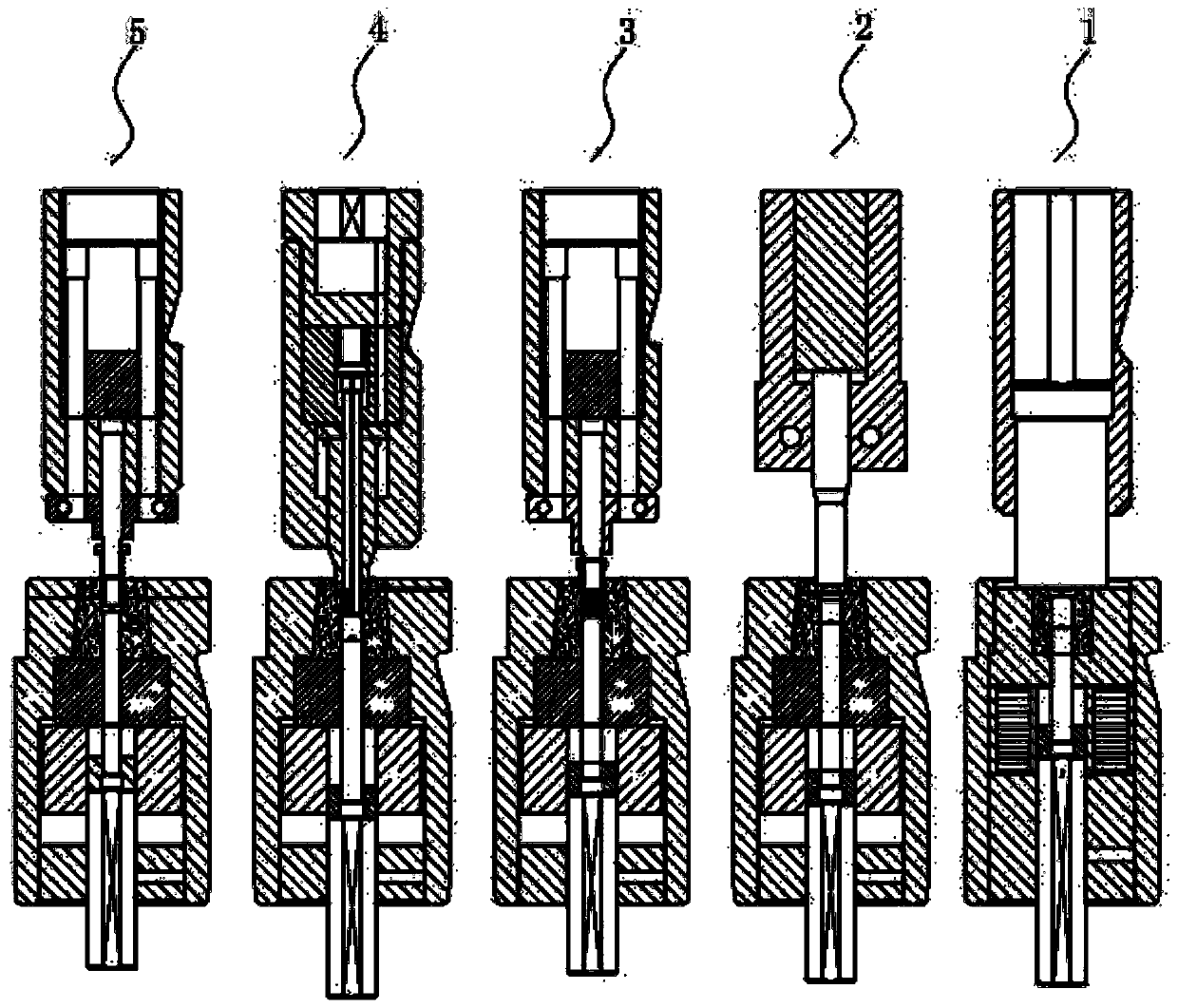

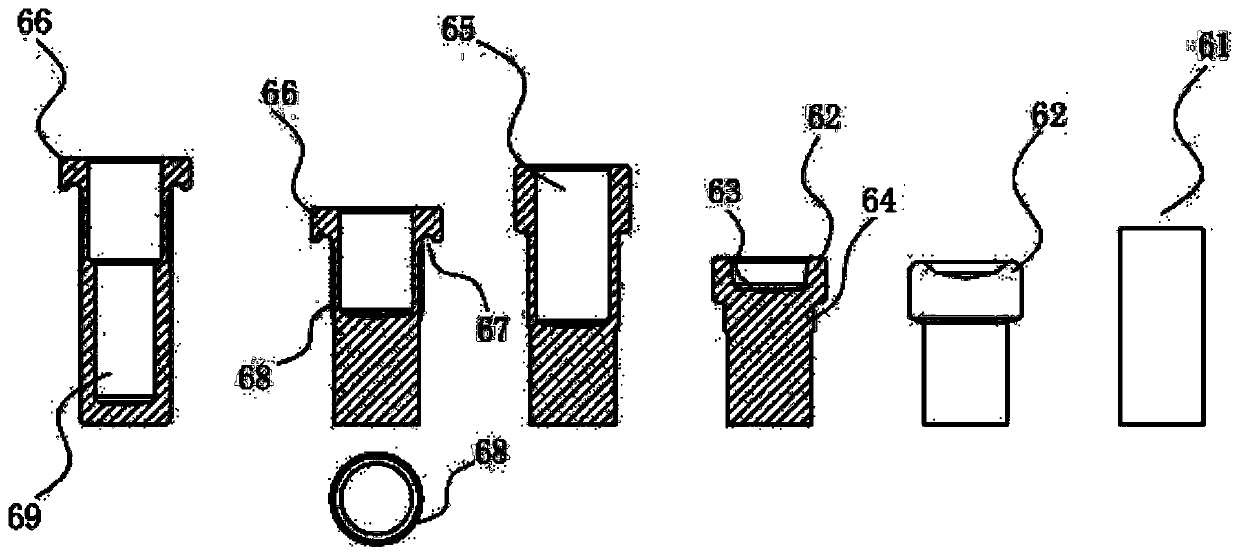

[0041] Embodiment one: see Figure 1~5 As shown, a cold heading device for forming blind rivet nuts includes a cold heading machine, and a mold assembly installed on the cold heading machine, and the mold assembly includes:

[0042] The first mold 1, the first mold 1 is used to make the upper part of the preset blank 61 form the preset head 62;

[0043] The second mold 2, the second mold 2 is used to form the fixed point 63 of the head in the preset head 62, and form a step 64 between the preset head 62 and the lower part of the preset blank 61;

[0044] The third mold 3, the third mold 3 is used to back-extrude the first inner hole 65 in the preset head 62 and the stepped portion 64;

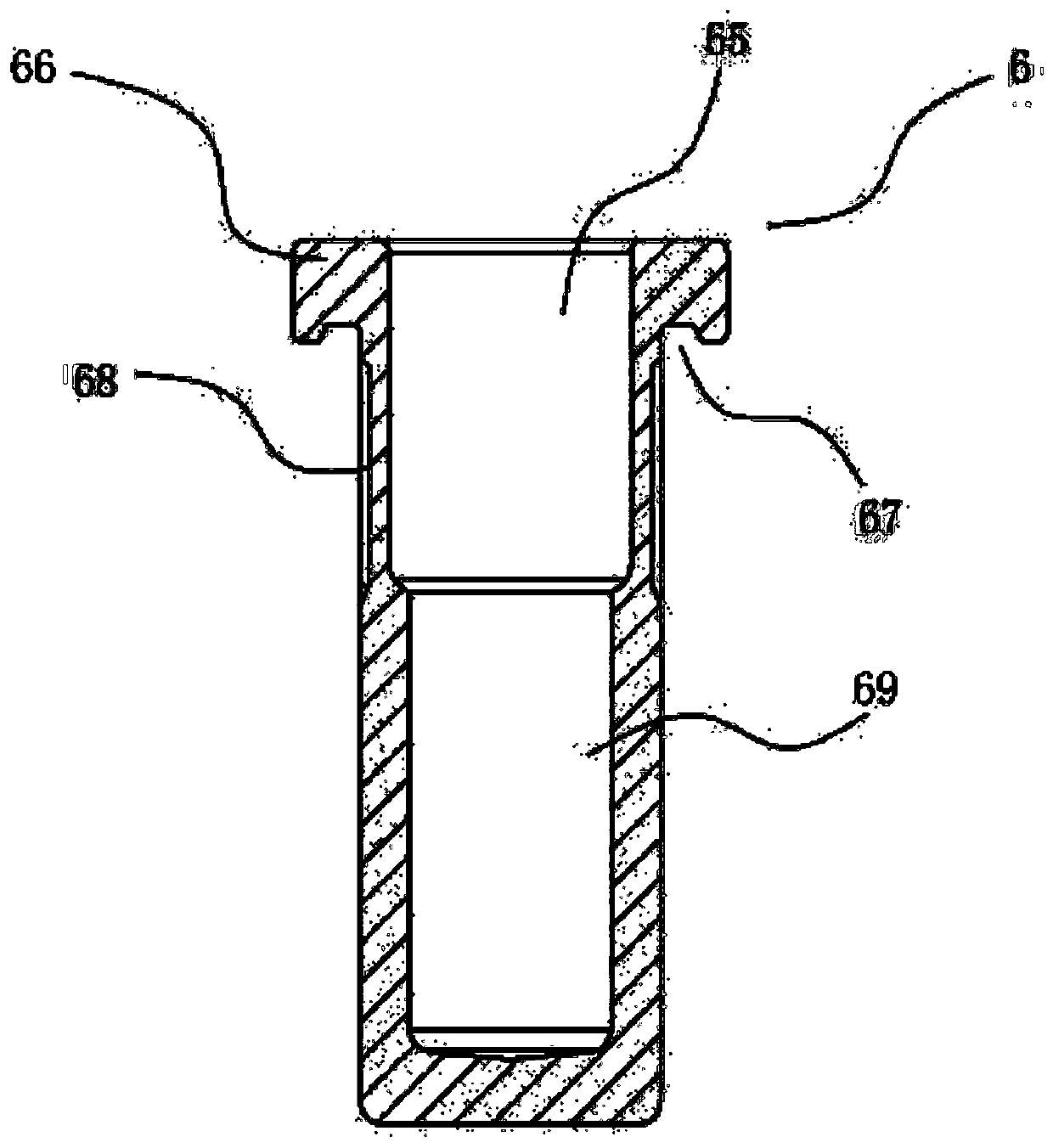

[0045] The fourth mold 4, the fourth mold 4 is used to form the preset head 62 into a flange portion 66, and form the stepped portion 64 into a flower tooth 68; the flange portion 66 includes a groove under the head 67;

[0046] The fifth mold 5, the fifth mold 5 is used to reversely extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com