Direct-connection-type intelligent joint

A direct-connected, intelligent technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve problems such as knowledge difficulties, high integration, complicated disassembly and assembly of harmonic reducers and servo motor modules, and achieve high structural compatibility. The effect of stable output and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

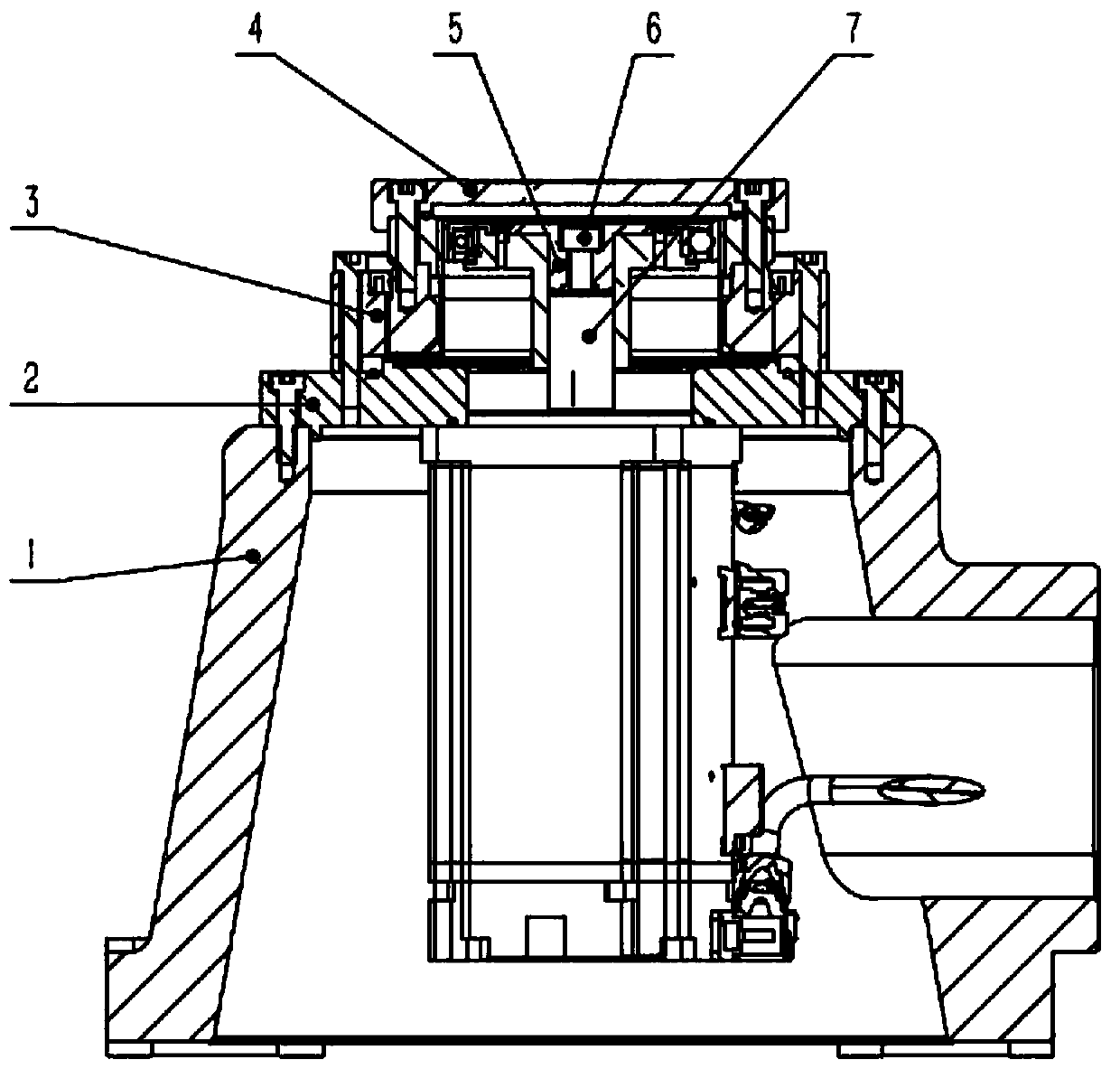

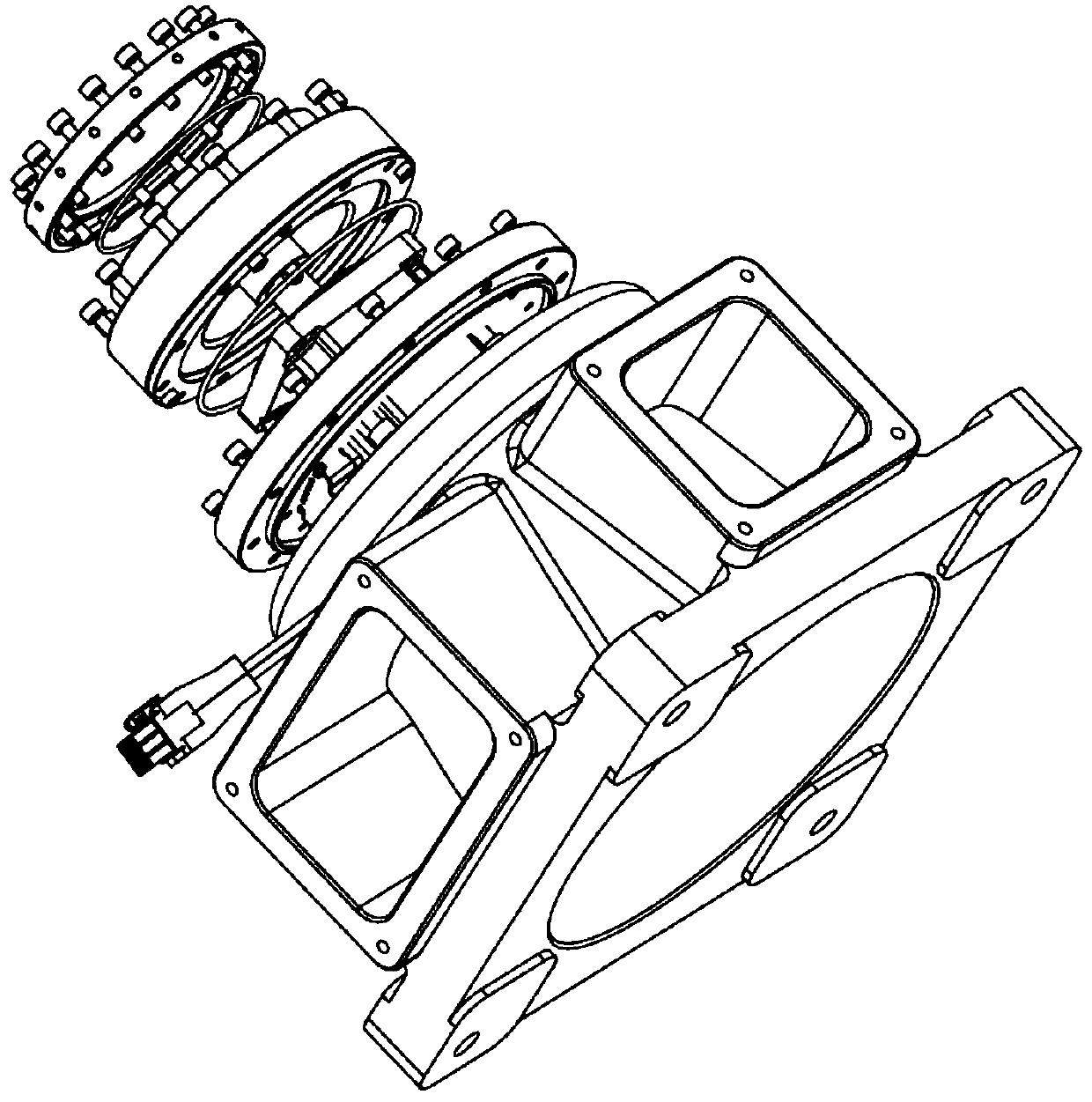

[0016] Example 1, such as Figure 1 to Figure 2 Shown:

[0017] A direct-connected intelligent joint, comprising a base 1 and a transition flange 2 at its top, the transition flange 2 is provided with a harmonic reducer 3, one end of the harmonic reducer 3 is provided with an output flange 4, and the base 1 is also provided with a There is a servo motor 7, the servo motor 7 is connected to the wave generator 5, and the wave generator 5 is located inside the output flange 4.

[0018] 2. A direct-connected intelligent joint according to claim 1, characterized in that the base 1 is fixedly connected with the transition flange 2 through screws.

[0019] In a preferred technical solution of this embodiment, the transition flange 2 is fixedly connected to the harmonic reducer 3 through screws.

[0020] In a preferred technical solution of this embodiment, the harmonic reducer 3 is fixedly connected to the output flange 4 through screws.

[0021] In a preferred technical solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com