Electric heating unit mold and method for preparing electric heating unit assembly

A unit component, electric heating technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of poor density, affecting the aerodynamic performance of blades, difficult to manufacture, etc. The effect of breaking the opportunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

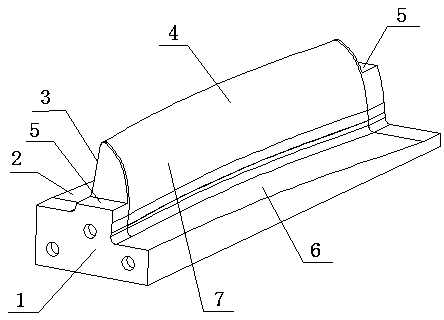

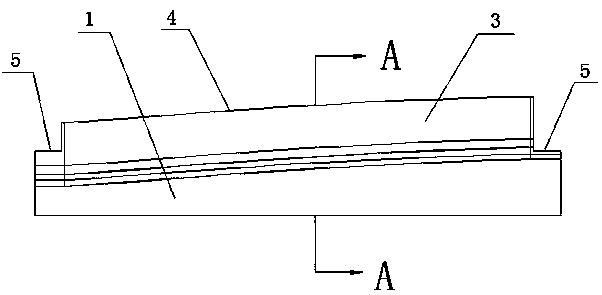

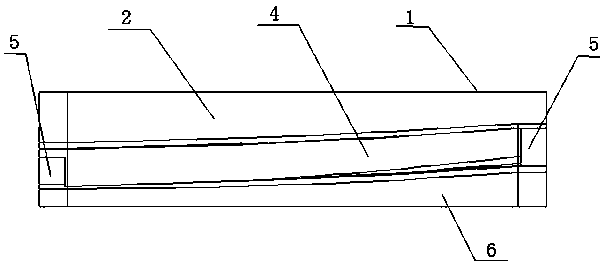

[0022] Such as Figure 1 to Figure 6 As shown, the electric heating unit mold of the present embodiment is one piece, the lower end is a base 1, and the base 1 protrudes upwards to a convex die 4 with the same shape and size as the leading edge of the blade body in the 1-2 layers of the skin. The upper end surfaces 5 of the base on the left and right sides of the punch 4 are planes, and the perimeter of the working surface end 3 of the punch 4 is the perimeter of the electric heating unit assembly 4 wrapping from the boundary line of the front edge of the blade body to the working surface end, and the non-working surface end The perimeter of 7 is the perimeter that the electric heating unit assembly wraps from the boundary line of the leading edge of the blade body to the end of the non-working surface. The upper end surfaces 2 and 6 of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com